High-refractive-index, high-toughness and vulcanization-resistant LED packaging silicone rubber

A technology of LED packaging and high refractive index, applied in adhesives, polymer adhesive additives, non-polymer adhesive additives, etc. To avoid problems such as damage, to achieve excellent substrate adhesion, increase hardness, and increase cross-linking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

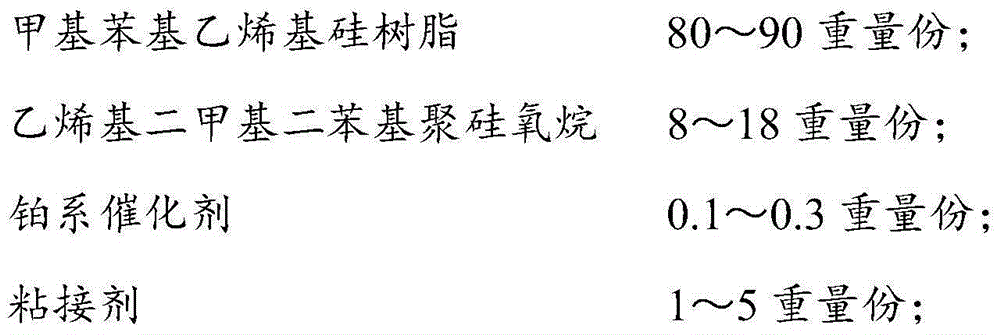

[0037] 1. Raw materials

[0038] Methylphenyl vinyl silicone resin: (ViMe 2 SiO 1 / 2 ) (PhSiO 3 / 2 ) 5 ;

[0039] Vinyl dimethyl diphenyl polysiloxane: (ViMe 2 SiO 1 / 2 ) 10 (ViMePh 2 SiO 1 / 2 ) 10 ;

[0040] The platinum series catalyst is a platinum-methylphenyl polysiloxane complex;

[0041] Methylphenyl hydrogen silicone resin: (HMe 2 SiO 1 / 2 ) 3 (MePhSiO 1 / 2 ) 5 (PhSiO 3 / 2 ) 4 ;

[0042] Hydrogen-terminated diphenyl polysiloxane: (HMe 2 SiO 1 / 2 ) 1 (Ph 2 SiO 1 / 2 ) 4 ;

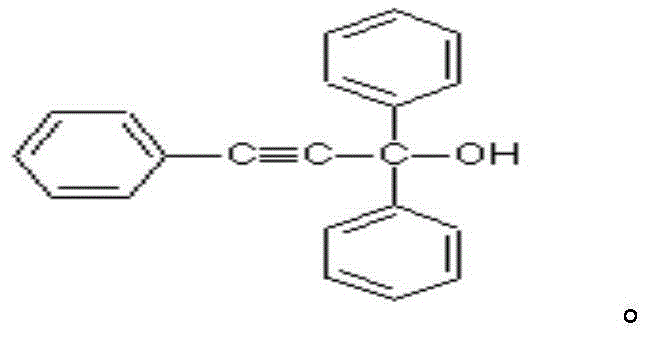

[0043] The inhibitor is ethynylcyclohexanol.

[0044] 2. Preparation method

[0045]Preparation of component A: Weigh 80 parts of methylphenyl vinyl silicone resin, 18 parts of vinyl dimethyl diphenyl polysiloxane, 0.1 part of platinum catalyst, and 2.9 parts of adhesive, and add them into the mixer in turn for mixing Stir evenly for 3 hours to obtain the A component;

[0046] Preparation of component B: Weigh 40 parts of dimethyl diphenyl hydrogen-containing silicone resin, 59.8 p...

Embodiment 2

[0049] 1. Raw materials

[0050] Methylphenyl vinyl silicone resin: (ViMe 2 SiO 1 / 2 ) (PhSiO 3 / 2 ) 3.5 ;

[0051] Vinyl dimethyl diphenyl polysiloxane: (ViMe 2 SiO 1 / 2 ) 70 (ViMePh 2 SiO 1 / 2 ) 70 ;

[0052] The platinum series catalyst is a platinum-olefin complex;

[0053] Methylphenyl hydrogen silicone resin: (HMe 2 SiO 1 / 2 ) 3 (MePhSiO 1 / 2 ) 4 (PhSiO 3 / 2 ) 4 ;

[0054] Hydrogen-terminated diphenyl polysiloxane: (HMe 2 SiO 1 / 2 ) 1 (Ph 2 SiO 1 / 2 ) 5 ;

[0055] The inhibitor is 1,1,3-triphenyl-2-propyn-1-ol.

[0056] 2. Preparation method

[0057] Preparation of component A: Weigh 90 parts of methylphenyl vinyl silicone resin, 8 parts of vinyl dimethyl diphenyl polysiloxane, 0.3 parts of platinum catalyst, and 1.0 parts of adhesive, and add them to the mixer in turn and mix them Stir evenly for 5 hours to obtain the A component;

[0058] Preparation of component B: Weigh 60 parts of dimethyl diphenyl hydrogen-containing silicone resin, 39.7 parts o...

Embodiment 3

[0061] 1. Raw materials

[0062] Methylphenyl vinyl silicone resin: (ViMe 2 SiO 1 / 2 ) 2 (PhSiO 3 / 2 ) 8 ;

[0063] Vinyl dimethyl diphenyl polysiloxane: (ViMe 2 SiO 1 / 2 ) 40 (ViMePh 2 SiO 1 / 2 ) 40 ;

[0064] The platinum series catalyst is a platinum-methylphenyl polysiloxane complex;

[0065] Methylphenyl hydrogen silicone resin: (HMe 2 SiO 1 / 2 ) 3 (MePhSiO 1 / 2 ) 6 (PhSiO 3 / 2 ) 4 ;

[0066] Hydrogen-terminated diphenyl polysiloxane: (HMe 2 SiO 1 / 2 ) 1 (Ph 2 SiO 1 / 2 ) 6 ;

[0067] The inhibitor is 1,1,3-triphenyl-2-propyn-1-ol.

[0068] 2. Preparation method

[0069] Preparation of component A: Weigh 85 parts of methylphenyl vinyl silicone resin, 9.8 parts of vinyl dimethyl diphenyl polysiloxane, 0.2 parts of platinum catalyst, and 5 parts of adhesive into the mixer in sequence, Mix for 4 hours and stir evenly to obtain the A component;

[0070] Preparation of component B: Weigh 50 parts of dimethyl diphenyl hydrogen-containing silicone resin, 49.9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com