A kind of plugging agent for drilling fluid and preparation method thereof

A technology for plugging agent and drilling fluid, applied in the field of plugging agent for drilling fluid and its preparation, can solve the problems of lack of bridging materials, reduced permeability of filter cake, difficult realization, etc. The effect of pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

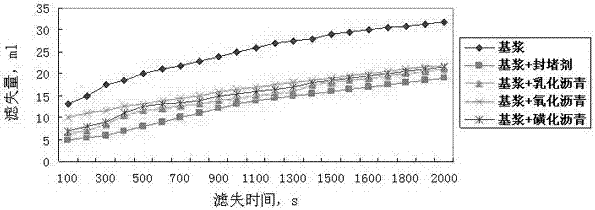

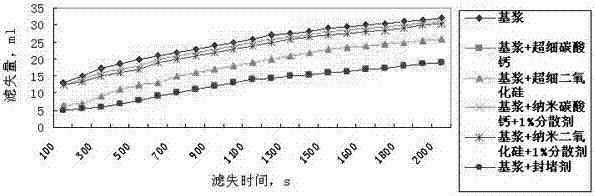

Image

Examples

Embodiment 1

[0040] Embodiment 1: a kind of plugging agent for drilling fluid, it is made up of following raw material of heavy part:

[0041]

[0042]

[0043] The preparation method of plugging agent for above-mentioned drilling fluid, it may further comprise the steps:

[0044] S1. Ingredients according to the proportion of the above formula, set aside;

[0045] S2. Add natural solid asphalt particles into the container, heat to 130°C, add one-third volume of No. 5 white mineral oil to dilute, and cool the diluted natural solid asphalt particles to 100°C;

[0046] S3. Heat the rosin particles in a heating kettle to 250°C, add castor oil and continue heating for 1h, heat to 280°C, then stir and cool to 200°C;

[0047] S4. Add the mixture of rosin granules and castor oil obtained in step S3 to the natural solid asphalt granules cooled in step S1, fully stir, add calcium carbonate granules and No. 5 white mineral oil of the remaining 2 / 3 volume, and stir evenly , to make a plugging...

Embodiment 2

[0048] Embodiment 2: a kind of plugging agent for drilling fluid, it is made up of following raw material of heavy part:

[0049]

[0050] The preparation method of plugging agent for above-mentioned drilling fluid, it may further comprise the steps:

[0051] S1. Ingredients according to the proportion of the above formula, set aside;

[0052] S2. Add natural solid asphalt particles into the container, heat to 180°C, add 1 / 4 volume of No. 5 white mineral oil to dilute, and cool the diluted natural solid asphalt particles to 130°C;

[0053] S3. Heat the rosin particles in a heating kettle to 280°C, add castor oil and continue heating for 3h, heat to 320°C, then stir and cool to 240°C;

[0054]S4. the mixture of the rosin particles and castor oil obtained in step S3 is added in the natural solid asphalt particles cooled in step S1, fully stirred, adding calcium carbonate particles and No. 5 white mineral oil of three-quarter volume, stirred evenly, A plugging agent for dril...

Embodiment 3

[0055] Embodiment 3: a kind of plugging agent for drilling fluid, it is made up of following raw material of weight part:

[0056]

[0057] The preparation method of plugging agent for above-mentioned drilling fluid, it may further comprise the steps:

[0058] S1. Ingredients according to the proportion of the above formula, set aside;

[0059] S2. Add natural solid asphalt particles into the container, heat to 140°C, add 1 / 5 volume of No. 5 white mineral oil to dilute, and cool the diluted natural solid asphalt particles to 108°C;

[0060] S3. Heat the rosin particles in a heating kettle to 262°C, add castor oil and continue heating for 1.5h, heat to 290°C, then stir and cool to 210°C;

[0061] S4. Add the mixture of rosin granules and castor oil obtained in step S3 to the natural solid asphalt granules cooled in step S1, fully stir, add calcium carbonate granules and No. 5 white mineral oil No. 5 white of the remaining four-fifths volume Mineral oil, stirred evenly, to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com