Transfer-printing highlight titanium porcelain plate and processing technology thereof

A processing technology, titanium porcelain technology, applied in the field of decorative panels and its processing technology, can solve the problems of poor fire resistance, casualties, toxic smoke, etc., achieve good impact resistance, low working temperature, and save processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

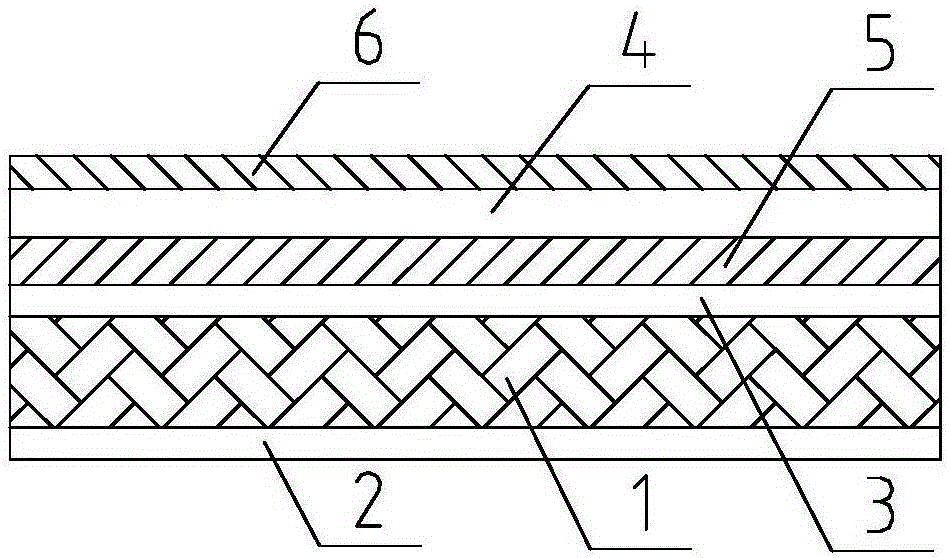

[0027] figure 1 It is a structural schematic diagram of a transfer printing high-gloss titania ceramic plate provided according to an embodiment of the present invention. figure 1 The shown transfer high-gloss titania plate includes a substrate 1, on the upper surface and the lower surface of the substrate 1, protective layers 3, 2 made of titanic paint are provided, above the protective layer 3 on the upper surface of the substrate A decorative layer 4 composed of a transfer film is provided, an adhesive layer 5 is provided between the decorative layer 4 and the protective layer 3 on the upper surface of the substrate, and an adhesive layer 5 is provided on the upper surface of the decorative layer 4. Protective layer composed of porcelain paint6.

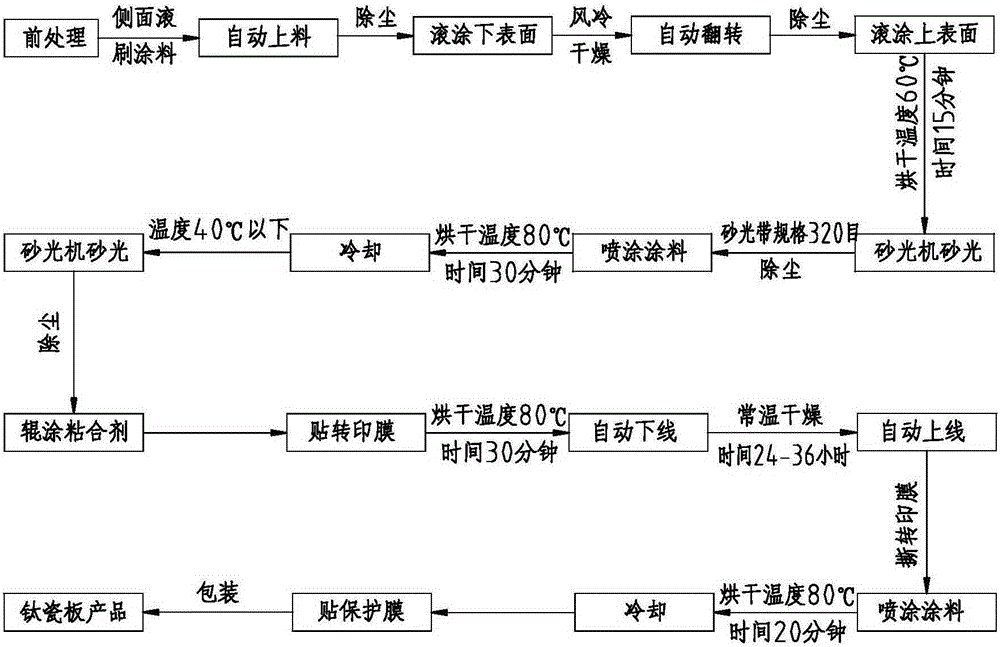

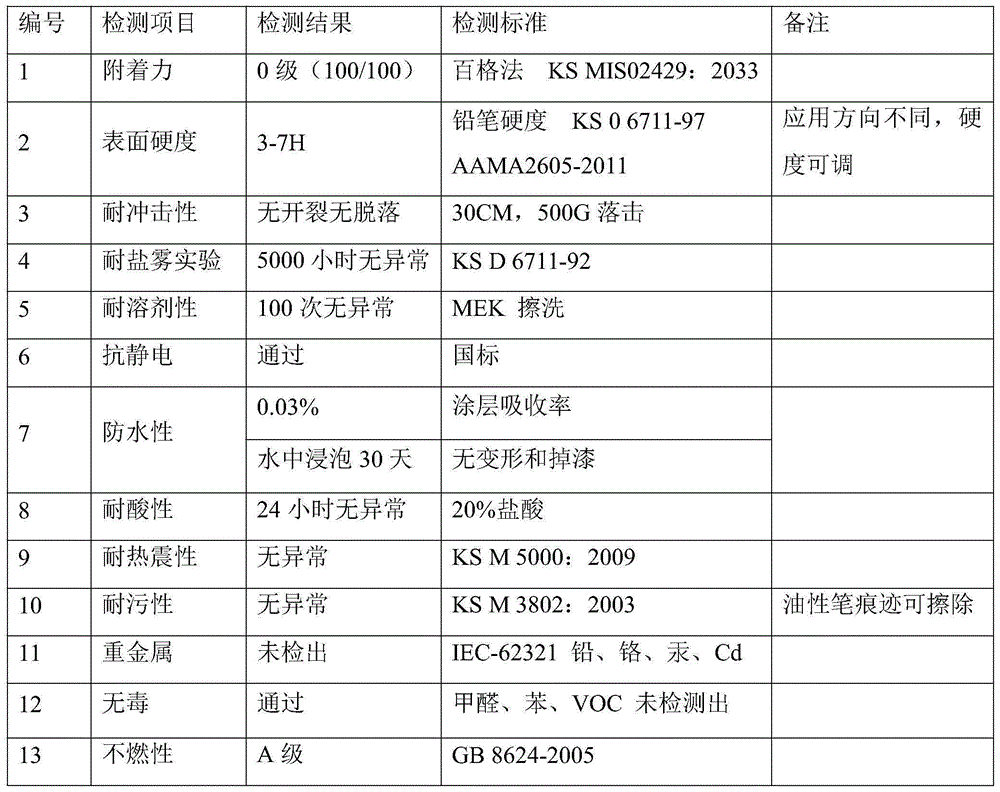

[0028] In the transfer printing high-gloss titania plate of the above-mentioned embodiment of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com