Preparation method of novel cobaltous dihydroxycarbonate-nitrogen-doped graphene combined electrode material

A technology of nitrogen-doped graphene and composite electrodes, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve problems such as difficulty in upgrading and pseudocapacitance bottlenecks, and achieve large effective specific surface area and good pseudocapacitive performance , the effect of good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 0.2g of graphite oxide powder into 100ml of deionized water, and sonicate for 1.0h at a power of 100W to obtain a graphene oxide suspension with a concentration of 2.0mg / ml; add 7.0mg of cobalt acetate under continuous stirring conditions to obtain Co 2+ The concentration of the solution is 8mM; then add ammonia water dropwise under the condition of 80°C water bath, adjust the pH of the mixed solution to 9.5, and then stir for 40min; transfer the 35ml water bath reaction solution into a 50ml reaction kettle, and react at 180°C for 12h; Cool naturally after the reaction, centrifuge the obtained product, wash repeatedly with absolute ethanol and deionized water for 3-5 times, and freeze-dry the precipitate for 12 hours to obtain the final product.

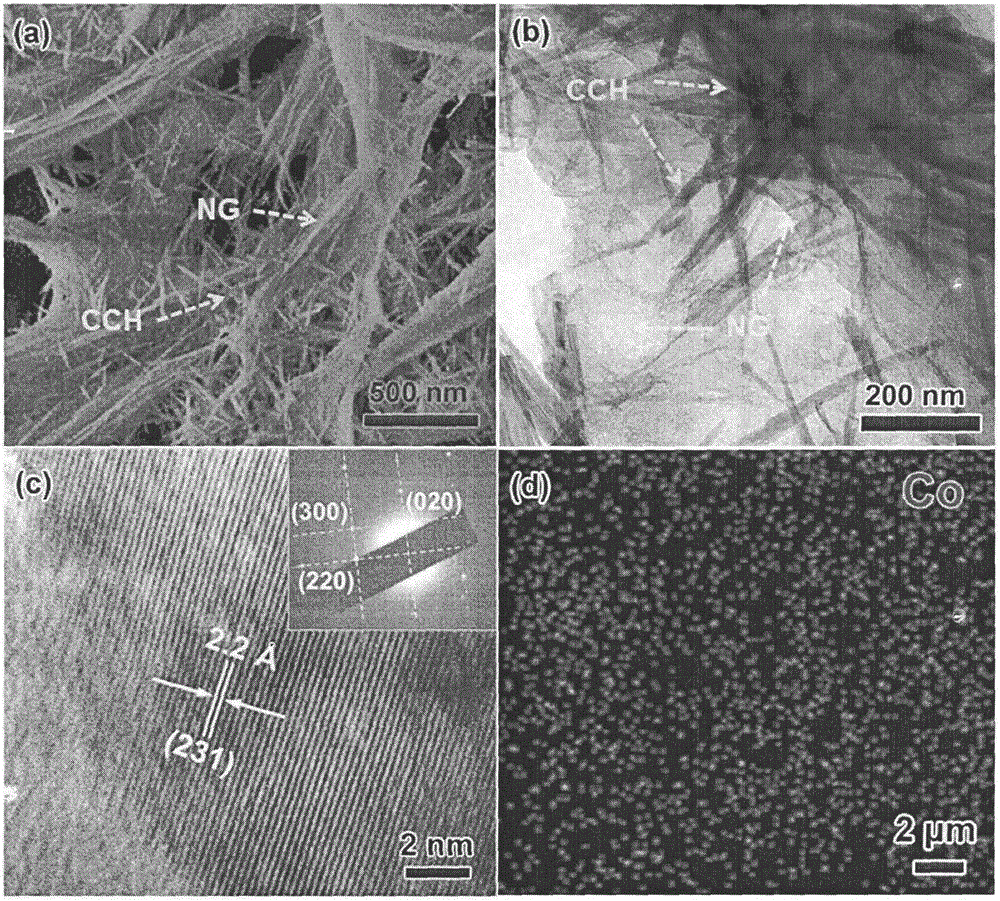

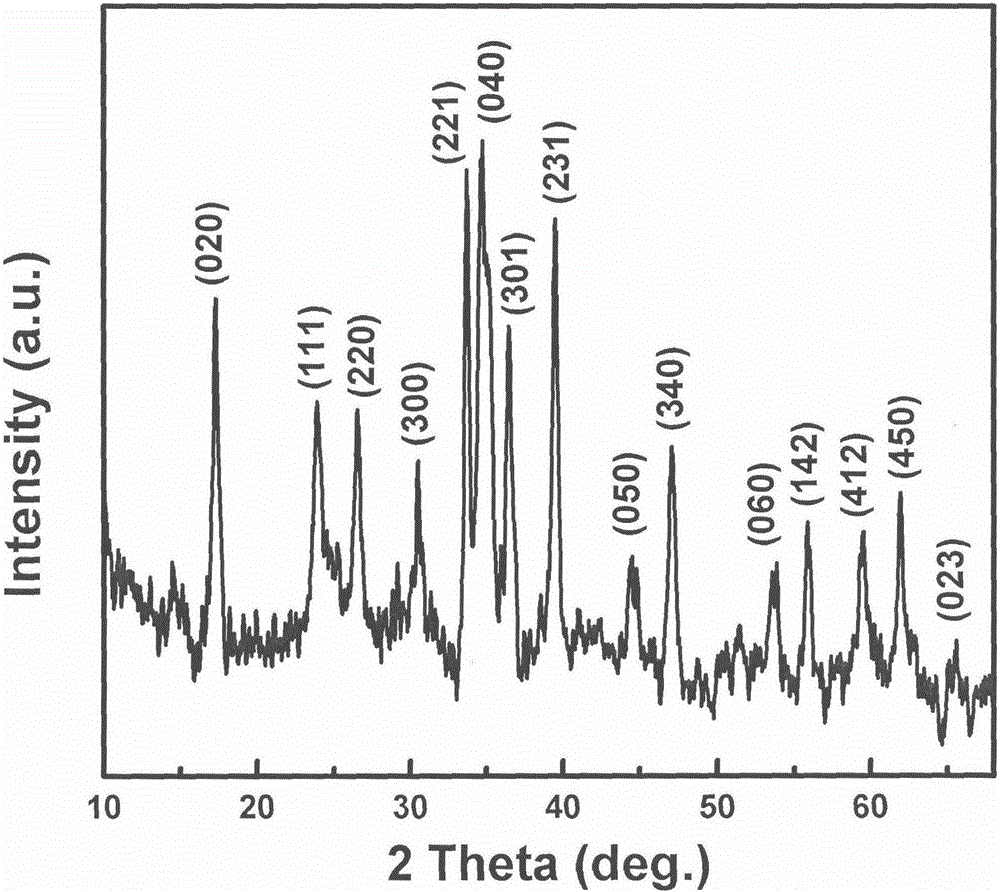

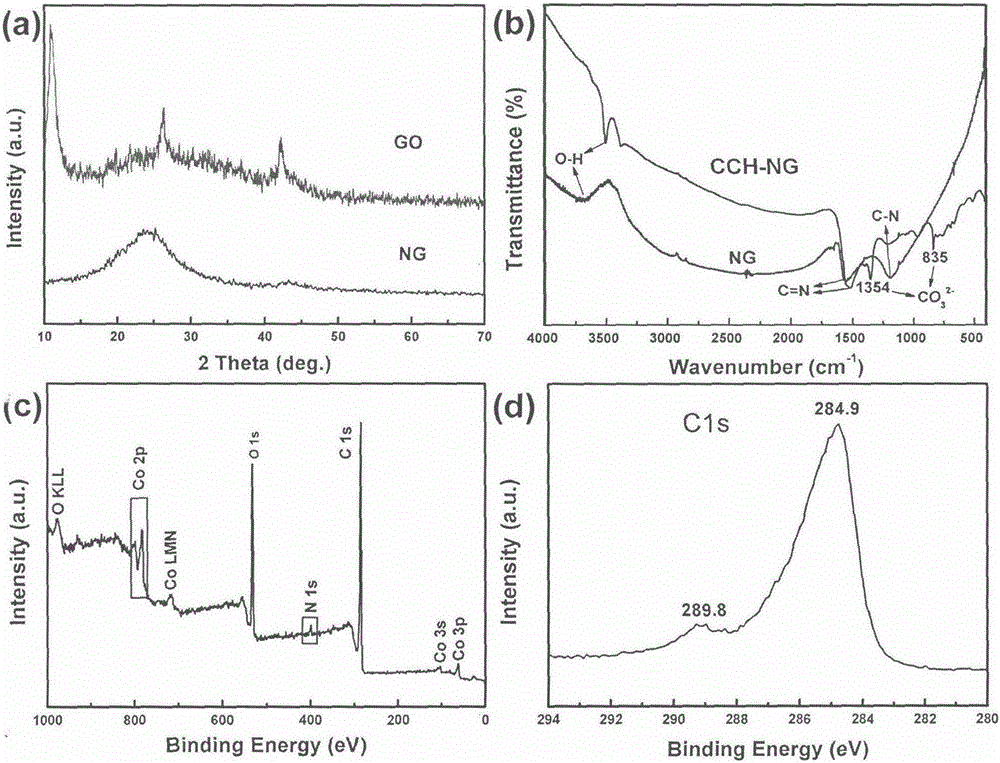

[0026] figure 1 (a) is the SEM picture of the product obtained in Example 1, as can be seen from the figure cobalt basic carbonate nanowires are evenly distributed in the nitrogen-doped graphene framework. figure 1 (b) Th...

Embodiment 2

[0031] Change Co 2+ The concentration is 2ml, and other conditions are identical with embodiment 1.

Embodiment 3

[0033] Change Co 2+ The concentration is 12ml, and other conditions are identical with embodiment 1.

[0034] Figure 5 (a)~(d) are in different Co 2+ The SEM and TEM images of the complex formed under concentration-response conditions. It can be seen from the figure that with the Co 2+ As the content increases, the number of basic cobalt carbonate nanowires increases, the length becomes longer, and the stacking becomes serious. When the reactant Co 2+ When the concentration is very high, the generated nanowires will cover the graphene, thereby reducing the capacitance performance of the composite, such as Figure 4 (b) (d) shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com