Sensorless permanent-magnet synchronous motor starting control method and corresponding system

A permanent magnet synchronous motor and sensor technology, which is applied in the control system, vector control system, motor generator control and other directions, can solve the problem of out-of-step of the starting control method, and achieve the effect of simple and easy-to-implement starting control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

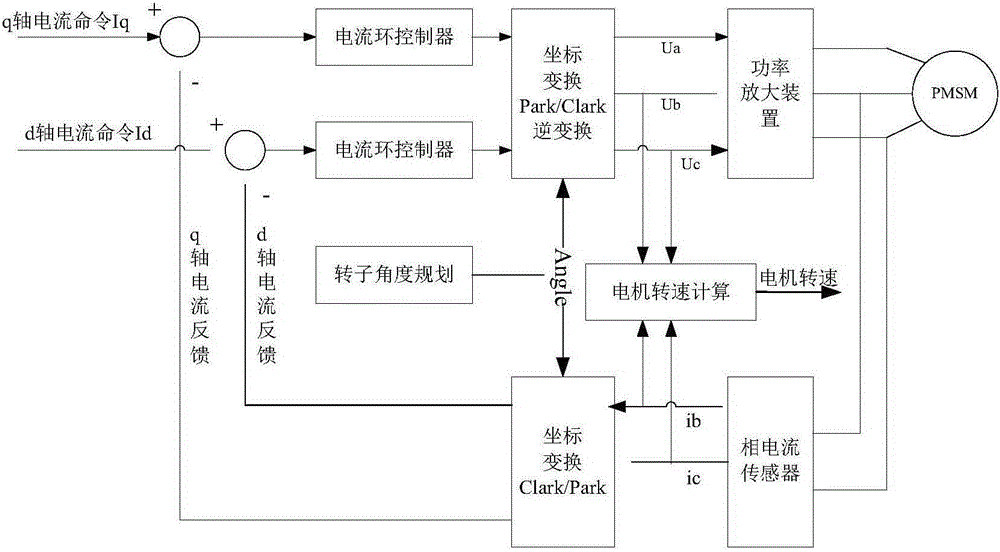

[0025] Such as figure 1 As shown, the permanent magnet synchronous motor starting control system of the present invention includes a motor control branch, a current feedback branch, an angle planning branch and a motor speed calculation branch, which constitute a motor current loop control mode.

[0026] The motor control branch includes a current comparator, a current loop controller, a Park / Clark inverse converter and a power amplifier; it is used to control the permanent magnet according to the q and d axis current control on the stator side of the permanent magnet synchronous motor in the given vector control For synchronous motors, the q-axis current on the stator side of the permanent magnet synchronous motor in the given vector control is 0, and the d-axis current is within the rated current value of the set multiple. The current commands of the d and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com