Solid-state imaging element, manufacturing method for same, curable composition for forming infrared cutoff filter, and camera module

A solid-state imaging element and a technology for a cut-off filter are applied to the solid-state imaging element of an infrared cut-off filter and its manufacture, a curable composition for forming an infrared cut-off filter, and a camera module field, which can solve the problems of increasing the number of pixels and the like , to achieve the effect of full infrared light shading ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0373] Hereinafter, examples of the present invention will be described, but the present invention is not limited to these examples. In addition, unless otherwise indicated, "part" and "%" are a mass basis.

Synthetic example 1

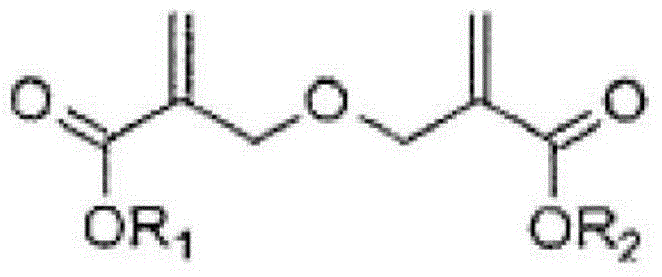

[0374] (Synthesis Example 1: Binder A)

[0375] 159 g of 1-methoxy-2-propanol was added to a 1,000 mL three-necked flask, and it heated to 85 degreeC under nitrogen stream. Prepared by adding 63.4 g of benzyl methacrylate, 72.3 g of methacrylic acid, and 4.15 g of V-601 (manufactured by Wako Pure Chemical Industries) to 159 g of 1-methoxy-2-propanol dropwise over 2 hours. solution. After completion of the dropwise addition, the reaction was further heated for 5 hours.

[0376] Then, heating was stopped, and the copolymer of benzyl methacrylate / methacrylic acid (30 / 70 mol ratio) was obtained.

[0377] Next, 120.0 g of the copolymer solution was transferred to a 300 mL three-necked flask, 16.6 g of glycidyl methacrylate and 0.16 g of p-methoxyphenol were added, stirred and dissolved. After dissolving, 3.0 g of triphenylphosphine was added, and it heated to 100 degreeC, and added reaction was performed. The disappearance of glycidyl methacrylate was confirmed by gas chromatog...

Synthetic example 2

[0378] (Synthesis Example 2: Binder D)

[0379] (ACA) 230AA (acid-group-containing methacrylic resin manufactured by Daicel-Cytec Co., Ltd. (acid group content is 0.7meq / g, cross-linking group content is 1.9meq / g) g, a weight average molecular weight of 14000 (polystyrene conversion value obtained by GPC method))) in a propylene glycol monomethyl ether (PGME; alias 1-methoxy-2-propanol) solution having a solid content of 55% by mass , PGME was further added to prepare a binder D solution having a solid content of 40% by mass.

[0380] (Red (Red) pigment dispersion: dispersion containing PR254 / PY139)

[0381] Using a bead mill (zirconia beads with a diameter of 0.3 mm), 9.6 parts of pigment red (PigmentRed) 254, 4.3 parts of pigment yellow (PigmentYellow) 139, 6.8 parts of pigment dispersant Bi Ke (BYK)-161 (manufactured by BYK) and 79.3 parts of propylene glycol methyl ether acetate (hereinafter referred to as "PGMEA") were mixed and dispersed for 3 hours to prepare a pigmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com