Composition for forming upper layer film and resist pattern forming method using same

一种组合物、图案的技术,应用在用于光机械设备的光敏材料、电气元件、半导体/固态器件制造等方向,能够解决污染光学系统或光掩模、曝光精度劣化等问题,达到优异图案、减轻深紫外线的影响、吸收率高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 101~121

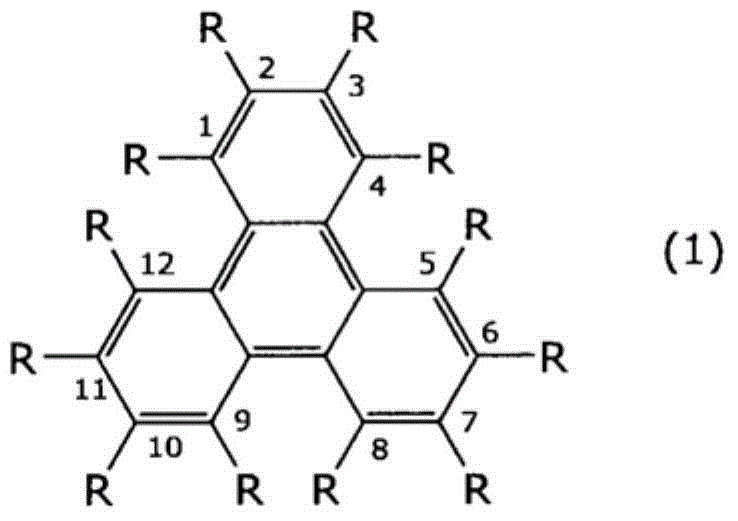

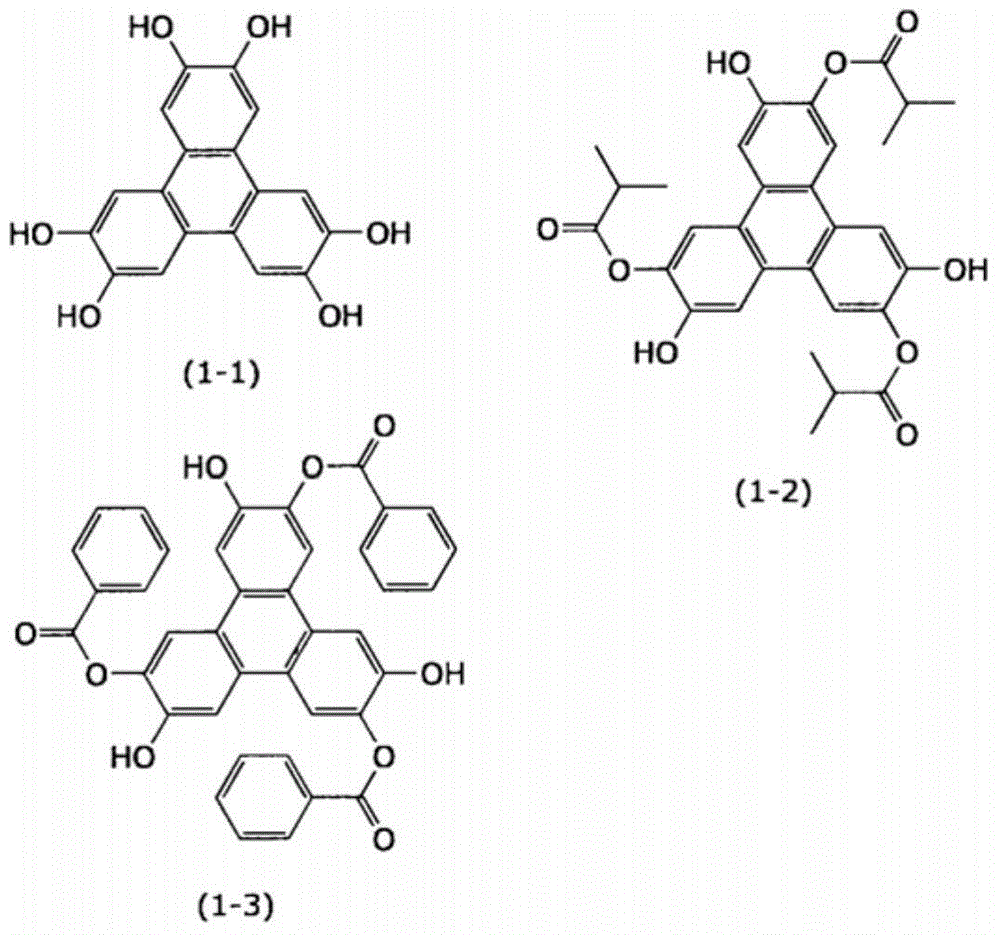

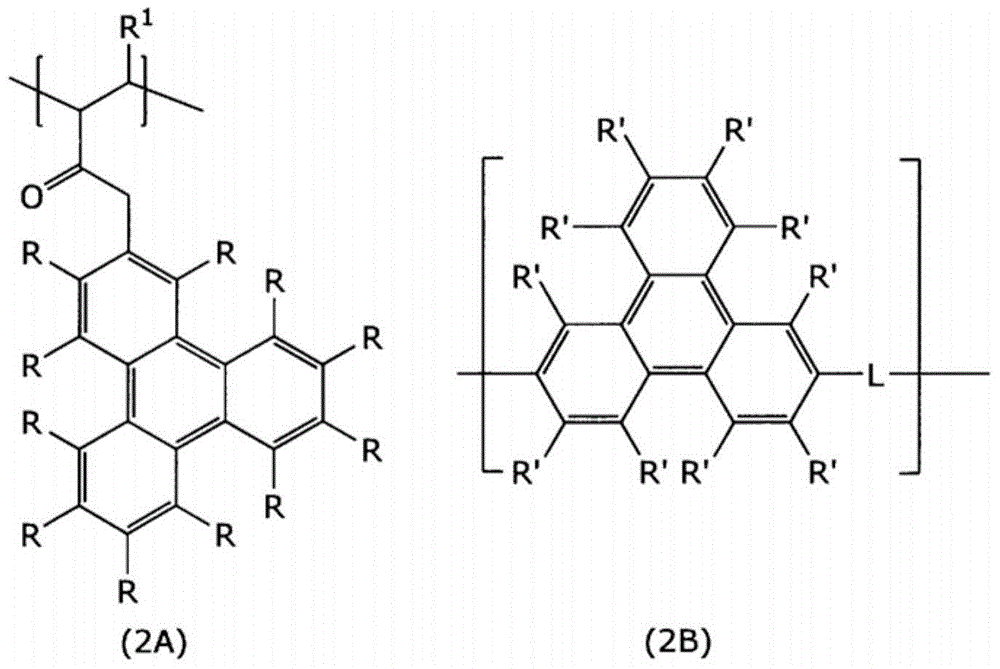

[0086] As triphenylene derivatives, the aforementioned compounds (1-1), (1-2), (1-3) and (2B-1) were prepared. Compound (1-1) used a commercial item. Compounds (1-2) and (1-3) are synthesized by reacting compound (1-1) as a raw material with a carboxylic anhydride compound. Specifically, compound (1-1) was dissolved in dimethylformamide, triethylamine was added and stirred for 10 minutes, thereafter, 3 equivalents of isobutyric anhydride or benzoic anhydride were added, and heated and stirred at 110°C for 2 hours , thereby reacting. The reaction mixture was cooled to room temperature, the solvent was distilled off by distillation under reduced pressure and concentrated until it became about half the amount. A 0.1 M hydrochloric acid aqueous solution was slowly added to the concentrated reaction mixture with stirring, to form a precipitate. The generated precipitate was separated by filtration, washed with water, and dried to obtain the target triphenylene derivative.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com