Magnetic doped magnetite heterogenous Fenton catalyst, preparation and application of catalyst in dye wastewater treatment

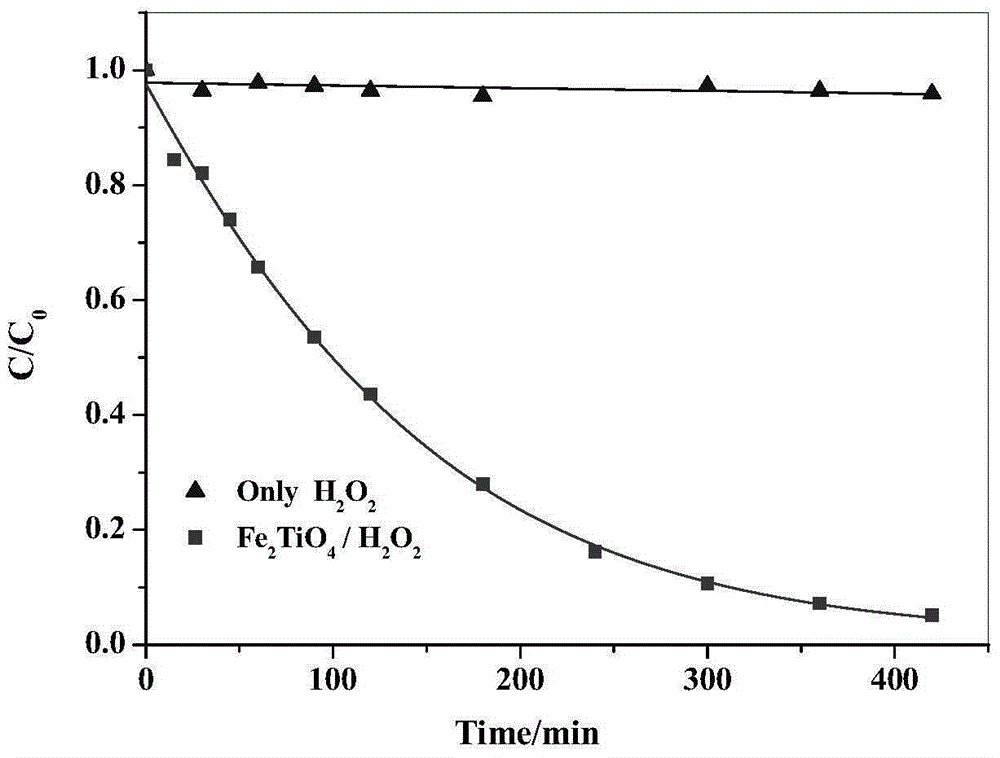

A technology of magnetic doping and dye wastewater, which is applied in oxidation water/sewage treatment, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of less anionic dyes and low catalyst purity. problem, to achieve the effect of reuse, good effect and high removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

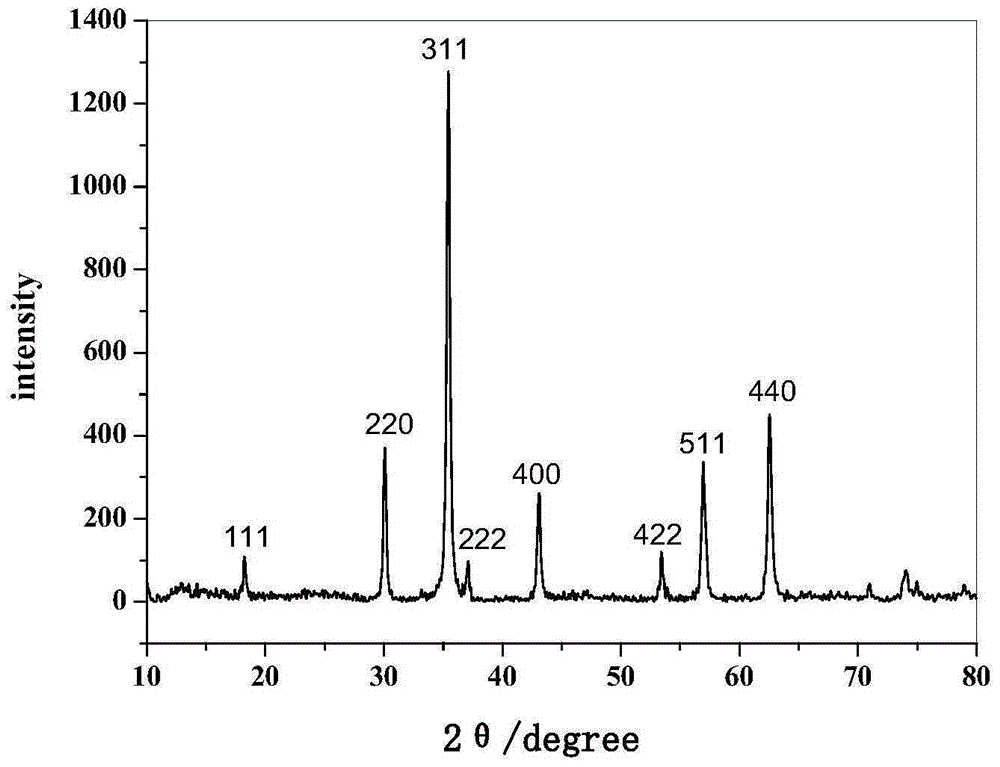

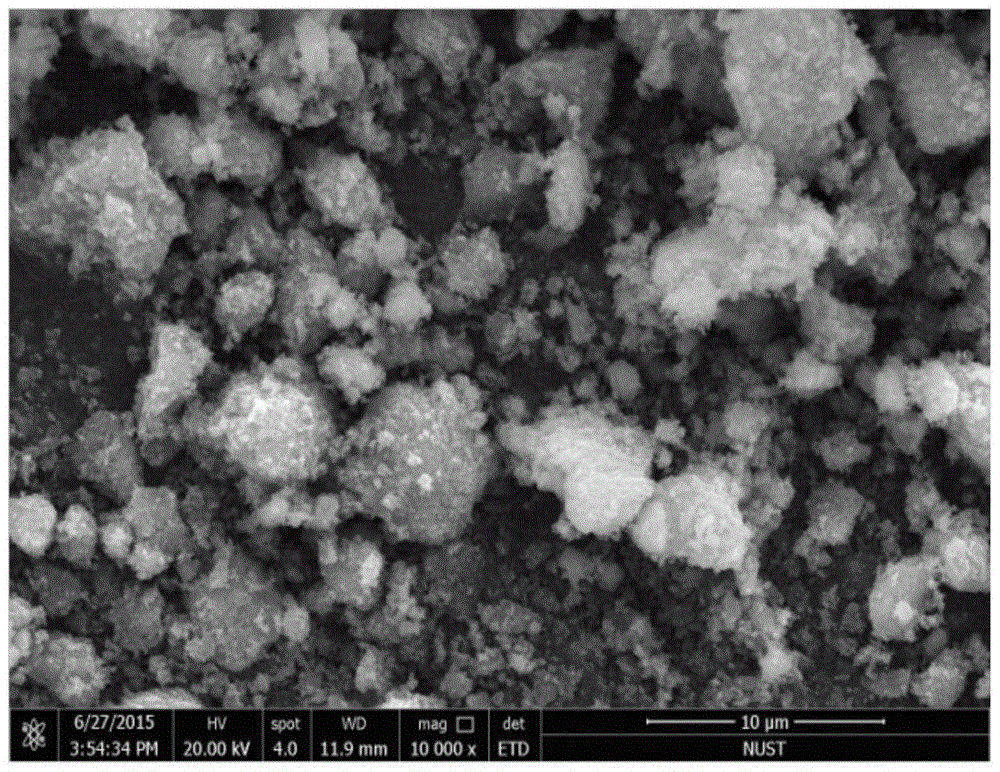

[0024] Embodiment one: pure phase TiFe 2 o 4 The preparation process and steps are as follows:

[0025] (1) Take an appropriate amount of ferrous sulfate and titanium tetrachloride respectively, according to the molar ratio Fe 2+ : Ti 4+ = Dissolve in deionized water at a ratio of 2:1 and stir evenly.

[0026] (2) Slowly add the mixed solution of metal ions obtained in (1) dropwise into an appropriate amount of ammonia alkali solution, and after the dropwise addition of the metal solution is completed, the reaction system is magnetically stirred for 2 hours.

[0027] (3) After the stirring is completed, the mixed solution is repeatedly washed with water and centrifuged to obtain a catalyst solid.

[0028] (4) The precipitate after centrifugation was dried in an oven at 100° C. for 12 hours.

[0029] (5) After the sample dried in step (4) is cooled, it is ground and sieved, and placed in a muffle furnace for calcination at 400° C. for 3 h. High-efficiency Magnetic Heterog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com