Preparation and application of a nitrogen-doped iron-based catalyst for Fischer-Tropsch reaction

A Fischer-Tropsch reaction and catalyst technology, used in the preparation of liquid hydrocarbon mixtures, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. High activity, simple method, and the effect of being beneficial to industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

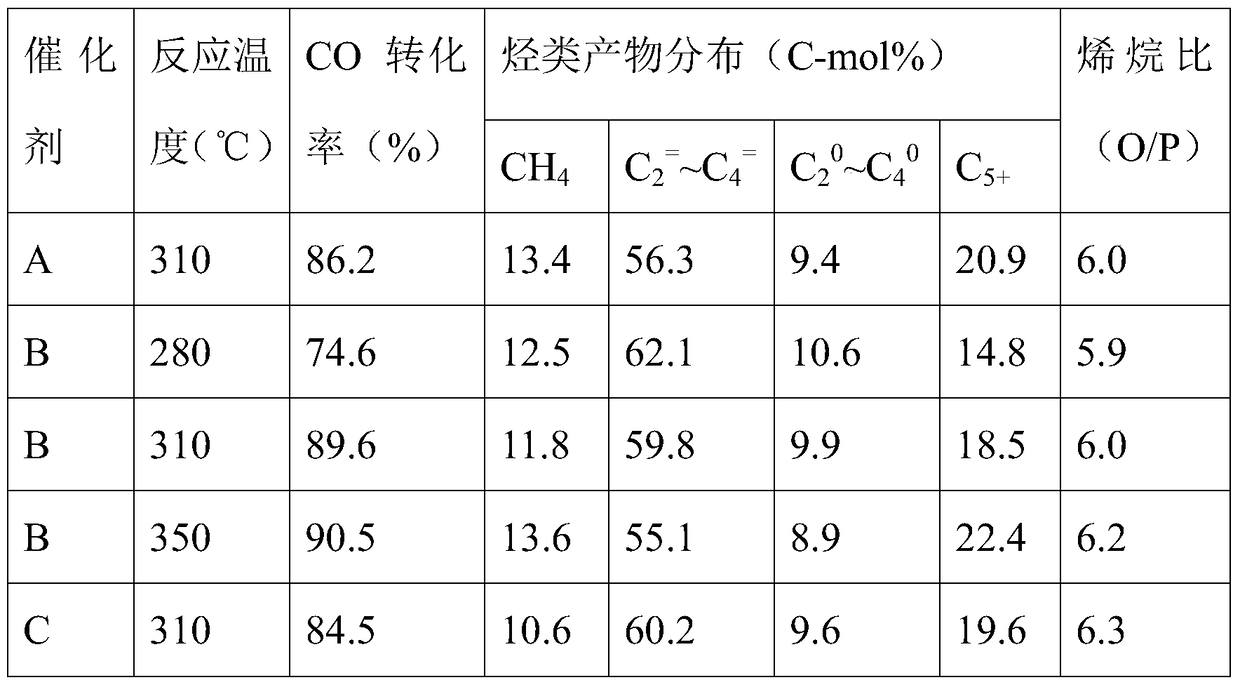

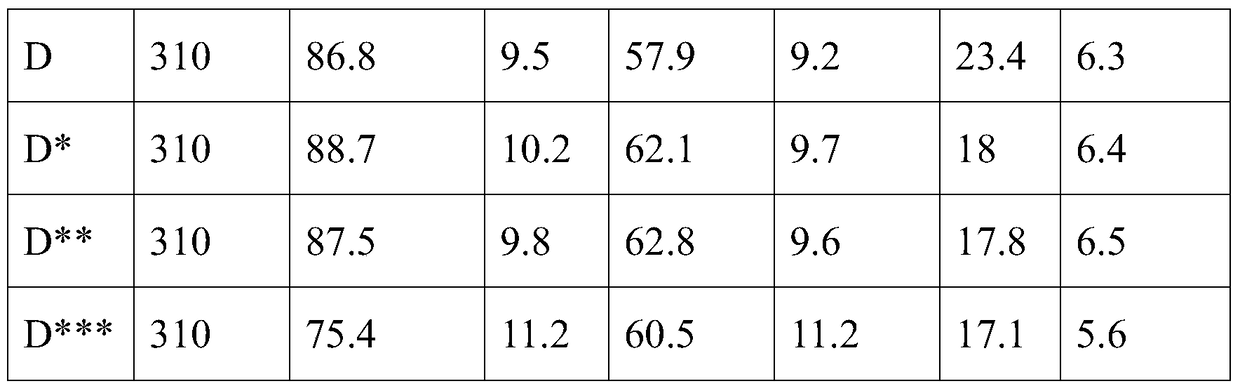

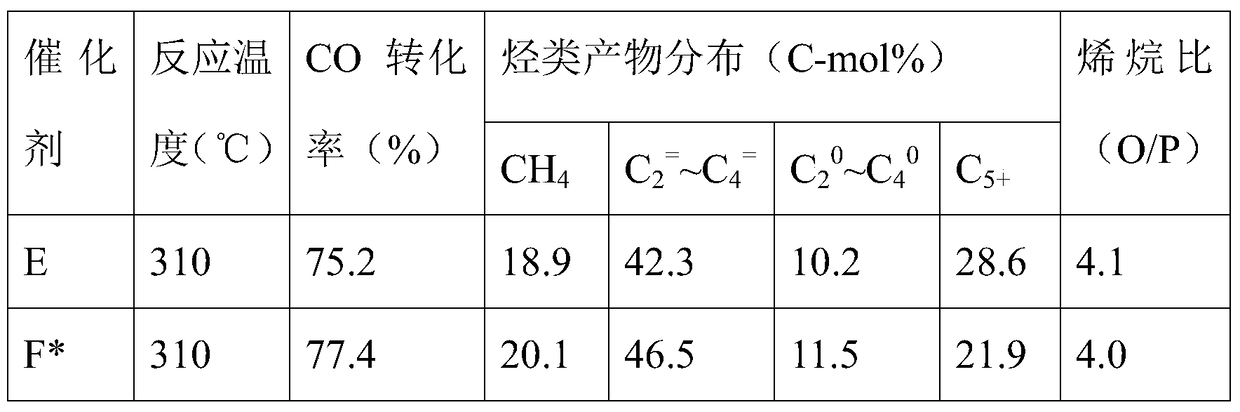

Embodiment 1

[0020] Take 2.372g of ferric nitrate, 2.05g of glucose, and 40g of melamine, respectively, and grind them in an agate mortar for 6h, then in a tube furnace in a nitrogen atmosphere at 2℃ / min from room temperature to 600℃ for 6h, then cool down To room temperature, Fe 2 O 3 Catalyst A with a content of 27.4wt%;

Embodiment 2

[0022] Take the ferric nitrate, glucose, and melamine in the same proportion as mentioned above and grind it in an agate mortar for 6 hours, then in a tube furnace in a nitrogen atmosphere at 2 ℃ / min from room temperature to 750 ℃, roast for 6 hours, and then cool to At room temperature, Fe is prepared 2 O 3 Catalyst B with a content of 26.2wt%;

Embodiment 3

[0024] Take the ferric nitrate, glucose, and melamine in the same proportion as mentioned above and grind it in an agate mortar for 6 hours, then in a tube furnace in a nitrogen atmosphere at 2°C / min from room temperature to 900°C for 6 hours, then cool to At room temperature, Fe is prepared 2 O 3 Catalyst C with a content of 25.9% by weight;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com