Real-time online tool wear monitoring method based on wavelet analysis and neural network

A neural network and wavelet analysis technology, applied in manufacturing tools, measuring/indicating equipment, metal processing machinery parts, etc., can solve problems such as inability to characterize local time-frequency characteristics of signals, discrete Fourier transform fence effects, and inability to process fuzzy signals. Achieve fast and efficient detection, shorten learning time, and achieve convenient results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

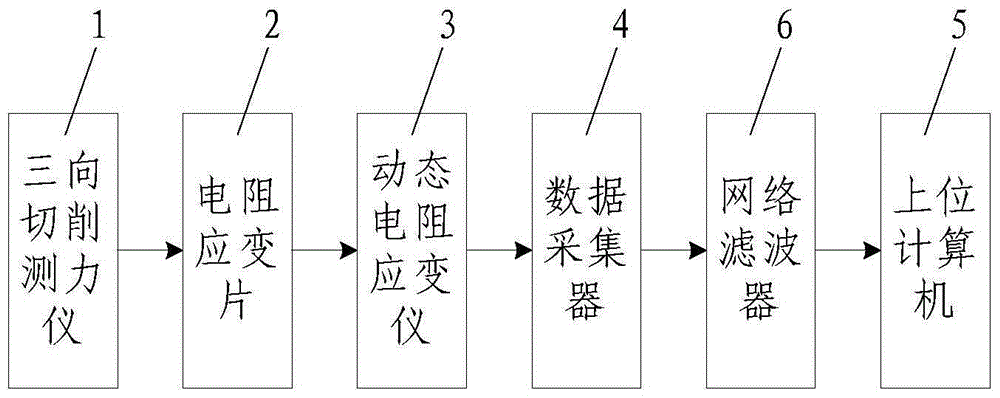

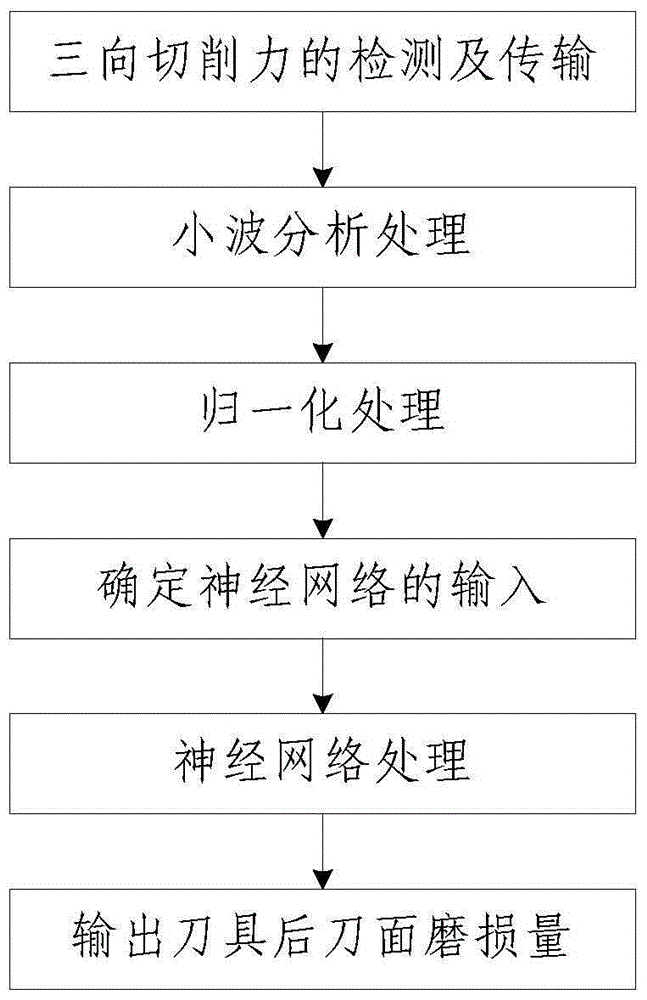

[0029] Such as figure 1 and figure 2 Shown, the tool wear real-time on-line monitoring method based on wavelet analysis and neural network of the present invention, comprises the following steps:

[0030] Step 1. Detection and transmission of the three-way cutting force: use the three-way cutting force gauge 1, the resistance strain gauge 2 pasted on the surface of the three-way cutting force gauge 1 and the dynamic resistance strain gauge 3 connected to the resistance strain gauge 2 Measure the three-way cutting force in real time, use the data collector 4 to collect the three-way cutting force, and use the network filter 6 to filter out the environmental noise interference signal and convert the three-way cutting force signal F x , F y and F z Transmission to host computer 5;

[0031] In this embodiment, the three-way cutting dynamometer 1 in step 1 is an octagonal ring type three-way cutting dynamometer, the dynamic resistance strain gauge 3 in step 1 is a SDY2101 dyna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com