Water-based paint bucket with oxidation-resistant and dustproof functions

A water-based paint, anti-oxidation technology, applied in the field of paint, can solve the problems of poor performance of water-based paint, water droplets, dust and mold, easy to stick to paint, etc., to reduce temperature difference, avoid pollution, and ensure the effect of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, further illustrate the present invention.

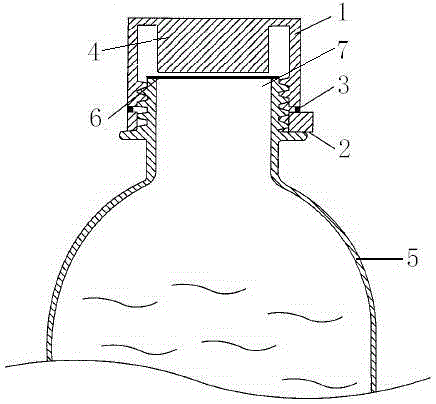

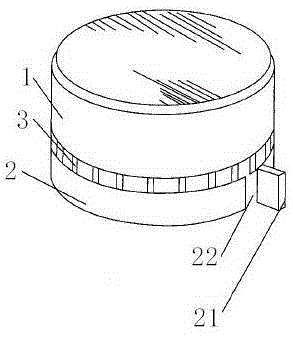

[0025] Such as figure 1 figure 2 As shown, a portable water-based paint bucket according to the present invention includes: a bottle cap body 1 , a pull ring 2 , a connecting post 3 , a bump 4 , a bottle body 5 , a plastic film 6 and a bottle mouth 7 .

[0026] The lower part of the side wall of the bottle cap body 1 is provided with an internal thread that cooperates with the external thread of the bottle mouth 7, a bump 4 is provided in the bottle cap body 1, and a connecting column 3 is provided in the middle of the bottle cap body 1 and the pull ring 2;

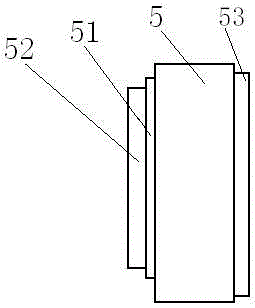

[0027] Such as image 3 As shown, an anti-corrosion layer 51 with a thickness of 50 μm to 100 μm is provided on the inner surface of the bottle body 5. The anti-corrosion layer is an epoxy resin coating layer, which can effectively avoid the metal dissolution of the metal container and cause the precipitation of dispersed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com