Method for improving two-stage decomposition effect

A seed, high-frequency multi-stage fine screening technology, applied in the direction of alumina/hydroxide, etc., can solve the problems that it is difficult to ensure the decomposition effect, quantitative control of seed particle size, etc., and achieve easy control, simple on-site commissioning and operation, and high operating efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

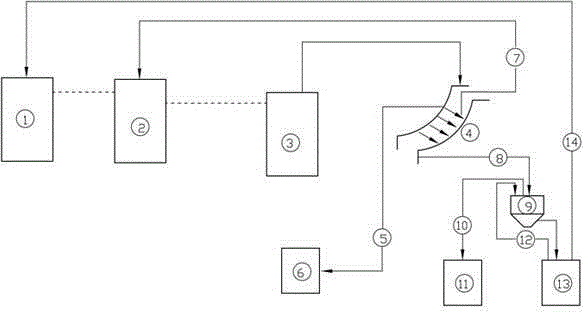

[0019] As shown in the figure, a method of improving the effect of the second-stage decomposition of the present invention, the discharge of the second-stage decomposition seed sorting tank 3 is pumped to the high-frequency multi-stage fine screen 4, and the first-stage screen size of the high-frequency multi-stage fine screen 100μm, the aluminum hydroxide product 5 on the high-frequency multi-stage fine sieve 4 flows to the flat plate filter 6 by itself, and then enters the roasting furnace to obtain alumina products; the under-sieve of the high-frequency multi-stage fine screen 4 enters the second Screen, the size of the secondary screen of the high-frequency multi-stage fine screen is 70 μm, the secondary sieve is added as coarse seeds 7 to the first tank 2 of the second-stage decomposition, the secondary sieve 8 enters the fine seed settlement tank 9, and the fine seeds The overflow of the seed settling tank 9 and the mother liquor 10 are sent to the evaporation process 11,...

Embodiment 2

[0021] As shown in the figure, a method of improving the effect of the second-stage decomposition of the present invention, the discharge of the second-stage decomposition seed sorting tank 3 is pumped to the high-frequency multi-stage fine screen 4, and the first-stage screen size of the high-frequency multi-stage fine screen 150μm, the aluminum hydroxide product 5 on the high-frequency multi-stage fine sieve 4 flows to the flat plate filter 6 by itself, and then enters the roasting furnace to obtain alumina products; Screen, the size of the secondary screen of the high-frequency multi-stage fine screen is 50 μm, the secondary sieve is added as coarse seeds 7 to the first tank 2 of the second-stage decomposition, the secondary sieve 8 enters the fine seed settlement tank 9, and the fine seeds The overflow of the seed settling tank 9 and the mother liquor 10 are sent to the evaporation process 11, and the bottom flow of the fine seed settling tank 9 enters the fine seed filter ...

Embodiment 3

[0023] As shown in the figure, a method of improving the effect of the second-stage decomposition of the present invention, the discharge of the second-stage decomposition seed sorting tank 3 is pumped to the high-frequency multi-stage fine screen 4, and the first-stage screen size of the high-frequency multi-stage fine screen 130μm, the aluminum hydroxide product 5 on the sieve of the high-frequency multi-stage fine sieve 4 flows to the flat plate filter 6 by itself, and then enters the roaster to obtain alumina products; the under-sieve of the high-frequency multi-stage fine sieve 4 enters the second Screen, the size of the secondary screen of the high-frequency multi-stage fine screen is 80 μm, the secondary sieve is added as coarse seeds 7 to the first decomposition tank 2 of the second stage, the secondary sieve 8 enters the fine seed settlement tank 9, and the fine seeds The overflow of the seed settling tank 9 and the mother liquor 10 are sent to the evaporation process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com