Preparation of zn-doped p-type β‑ga by chemical vapor deposition 2 o 3 nanowire approach

A technology of chemical vapor deposition and nanowires, applied in chemical instruments and methods, inorganic chemistry, nanotechnology, etc., can solve the problems of difficult doping of nanomaterials, and achieve the effects of overcoming preparation difficulties, simple equipment, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

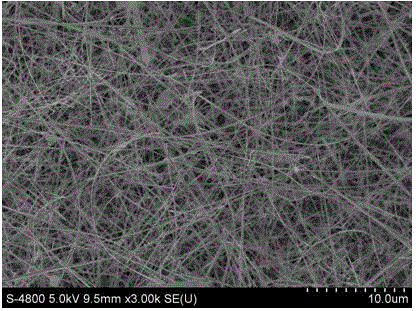

Embodiment 1

[0022] Proceed as follows:

[0023] a. first vapor-deposit a layer of metal catalyst with a thickness of 20nm on the cleaned substrate, the metal catalyst is gold;

[0024] b. The gallium source and the zinc source are fully mixed to make the reaction source material according to the mass ratio of 10:1, the gallium source is elemental gallium with a purity of 99%; the zinc source is a mixed powder of zinc oxide powder and carbon powder, The mass ratio of zinc oxide powder to carbon powder is 7:1;

[0025] c. Put the reaction source material and the substrate evaporated with the metal catalyst into the quartz boat, and then put the quartz boat into the high-temperature heating zone in the growth chamber of the chemical vapor deposition system. The substrate is located 1cm away from the reaction source material downstream of the gas flow , feed high-purity argon as the carrier gas, and the flow rate of argon is 200ml / min; when the heating temperature reaches 00°C, feed oxygen, ...

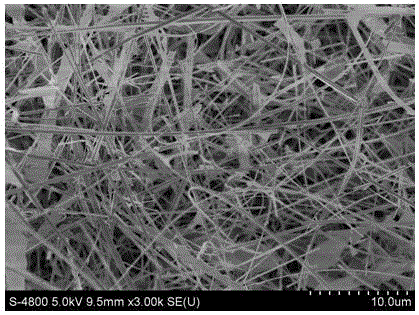

Embodiment 2

[0029] Proceed as follows:

[0030] a. On the cleaned substrate, vapor-deposit a metal catalyst with a thickness of 20nm, and the metal catalyst is gold;

[0031] b. The gallium source and the zinc source are fully mixed to make the reaction source material according to the mass ratio of 7:1, and the gallium source is elemental gallium with a purity of 99%; the zinc source is a mixed powder of zinc oxide powder and carbon powder, The mass ratio of zinc oxide powder to carbon powder is 7:1;

[0032] c. Put the reaction source material and the substrate evaporated with the metal catalyst into the quartz boat, and then put the quartz boat into the high-temperature heating zone in the growth chamber of the chemical vapor deposition system. The substrate is located 1cm away from the reaction source material downstream of the gas flow , feed high-purity argon as the carrier gas, and the flow rate of argon gas is 200ml / min; when the heating temperature reaches 900°C, feed oxygen, th...

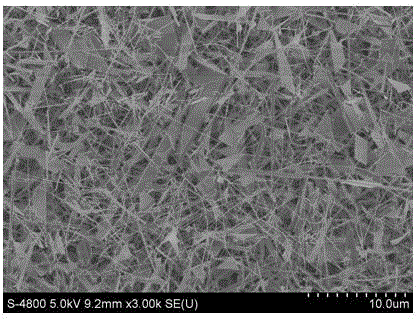

Embodiment 3

[0036] Proceed as follows:

[0037] a. On the cleaned substrate, vapor-deposit a metal catalyst with a thickness of 20nm, and the metal catalyst is gold;

[0038] b. The gallium source and the zinc source are fully mixed to make the reaction source material according to the mass ratio of 5:1, and the gallium source is elemental gallium with a purity of 99%; the zinc source is a mixed powder of zinc oxide powder and carbon powder, The mass ratio of zinc oxide powder to carbon powder is 7:1;

[0039] c. Put the reaction source material and the substrate evaporated with the metal catalyst into the quartz boat, and then put the quartz boat into the high-temperature heating zone in the growth chamber of the chemical vapor deposition system. The substrate is located 1cm away from the reaction source material downstream of the gas flow , feed high-purity argon as the carrier gas, and the flow rate of argon gas is 200ml / min; when the heating temperature reaches 900°C, feed oxygen, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com