Preparation method of zirconic acid sodium bismuthide lithium cerium doped potassium-sodium niobate based ceramic material

A technology based on sodium bismuth zirconate lithium cerium and potassium sodium niobate is applied in the field of preparation of sodium bismuth zirconate lithium cerium doped potassium sodium niobate based ceramic materials, which can solve the problems of doping and the like, and achieve the improvement of sintering activity, High density and good sintering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Preparation of potassium sodium niobate based ceramic powder by solid phase method

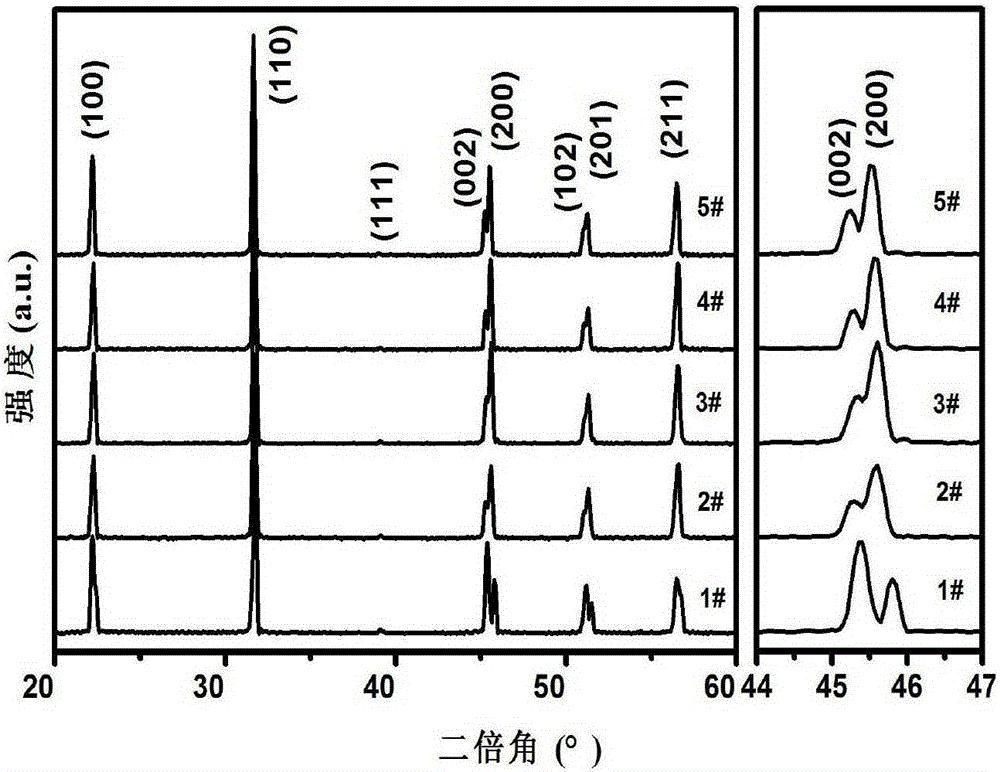

[0038] Raw material according to general formula K 0.48 Na 0.52 Nb0.95 Sb 0.05 o 3 (x=0.00, y=0.10, number 1 # ), carry out weighing, batching, put in the polyurethane ball mill jar, take absolute ethanol as dispersion medium, after ball milling with planetary ball mill for 12h, the rotating speed is 300rpm, bake 2h under drying lamp to make it dry, then in program control The temperature was continuously raised to 850° C. in an incubator furnace, and kept for 6 hours to obtain potassium sodium niobate-based ceramic powder.

[0039] (2) Granulation and tableting

[0040] Add a polyvinyl alcohol solution with a concentration of 8wt% to the above-mentioned dried powder, mix thoroughly and then granulate, and then press under a pressure of 10MPa to form bismuth sodium zirconate lithium cerium doped niobium with a diameter of 10mm and a thickness of 1.0mm Potassium sodium based ce...

Embodiment 2

[0046] (1) Preparation of potassium sodium niobate based ceramic powder by solid phase method

[0047] According to the general formula 0.97K 0.48 Na 0.52 Nb 0.95 Sb 0.05 o 3 -0.03 (Bi 0.5 Na 0.5 ) 0.9 (Li 0.5 Ce 0.5 ) 0.1 ZrO 3 (x=0.03, y=0.10, number 2 # ), carry out weighing, batching, put in the polyurethane ball mill jar, take absolute ethanol as dispersion medium, after ball milling with planetary ball mill for 12h, the rotating speed is 300rpm, bake 2h under drying lamp to make it dry, then in program control The temperature was continuously raised to 850° C. in an incubator furnace, and kept for 6 hours to obtain potassium sodium niobate-based ceramic powder.

[0048] (2) Granulation and tableting

[0049] Add a polyvinyl alcohol solution with a concentration of 8wt% to the above-mentioned dried powder, mix thoroughly and then granulate, and then press under a pressure of 10MPa to form bismuth sodium zirconate lithium cerium doped niobium with a diameter o...

Embodiment 3

[0055] (1) Preparation of potassium sodium niobate based ceramic powder by solid phase method

[0056] Raw materials according to the general formula 0.9675K 0.48 Na 0.52 Nb 0.95 Sb 0.05 o 3 -0.0325 (Bi 0.5 Na 0.5 ) 0.9 (Li 0.5 Ce 0.5 ) 0.1 ZrO 3 (x=0.0325, y=0.10, number 3 # ), carry out weighing, batching, put in the polyurethane ball mill jar, take absolute ethanol as dispersion medium, after ball milling with planetary ball mill for 12h, the rotating speed is 300rpm, bake 2h under drying lamp to make it dry, then in program control The temperature was continuously raised to 850° C. in an incubator furnace, and kept for 6 hours to obtain potassium sodium niobate-based ceramic powder.

[0057] (2) Granulation and tableting

[0058] Add a polyvinyl alcohol solution with a concentration of 8wt% to the above-mentioned dried powder, mix thoroughly and then granulate, and then press under a pressure of 10MPa to form bismuth sodium zirconate lithium cerium doped niobi...

PUM

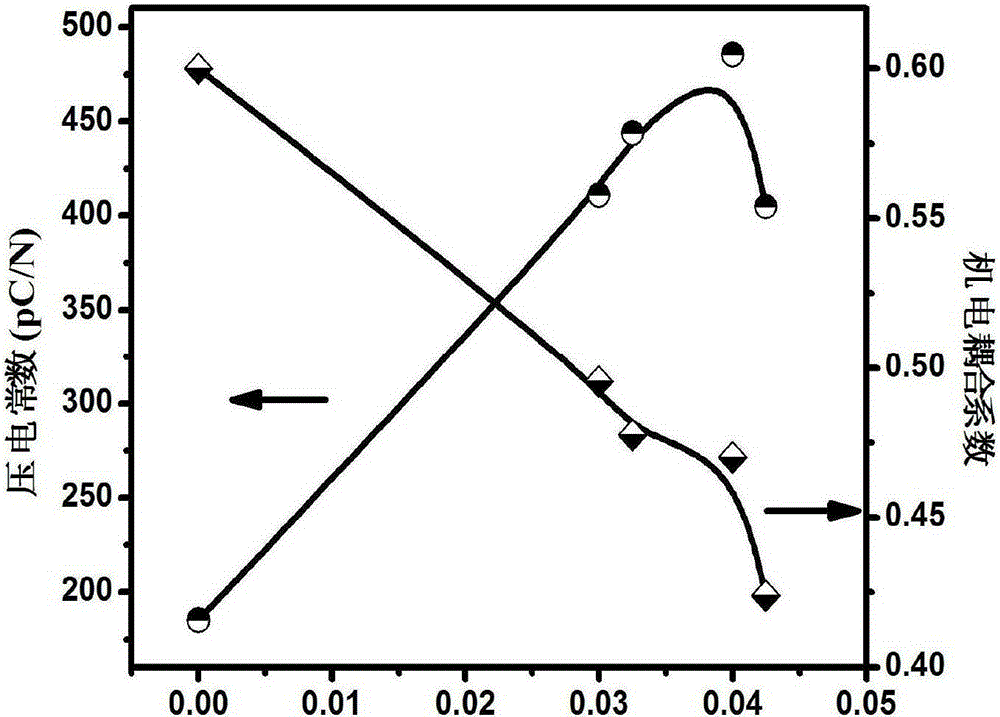

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com