A method for preparing rare earth-doped tungsten oxide nanostructure film

A nanostructure, rare earth doping technology, applied in chemical instruments and methods, luminescent materials, etc., can solve problems such as changes in material structure and electronic energy band structure, changes in optical properties of materials, etc., and achieves good crystallinity, simple preparation method, The obvious effect of fluorescence performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

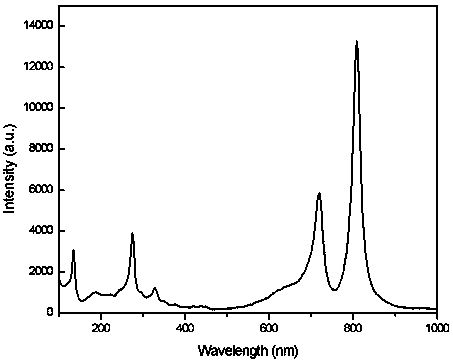

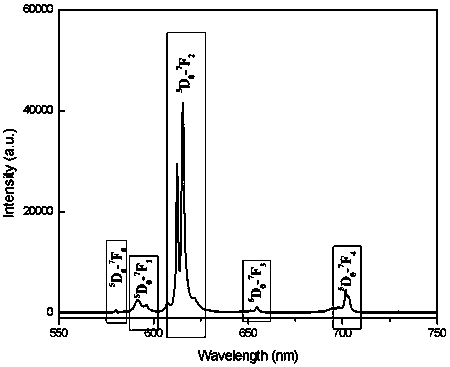

Embodiment 1

[0022] 1) Silicon wafers (20*20 mm 2 ) Ultrasonic cleaning in alcohol and deionized water for 15 min, and then drying in an oven at 120 °C;

[0023] 2) Weigh 0.4504 g of tungsten powder and 0.0508 g of europium oxide powder respectively, mix and grind them for 10 minutes, spread them evenly in the tungsten boat, place the dried silicon substrate on the tungsten boat, the distance between the tungsten boat and the substrate is 4 mm ;

[0024] 3) Vacuumize the chamber. When the vacuum degree is 7.0 Pa, inject Ar 30 sccm and stabilize for 20 min;

[0025] 4) Turn on the evaporation current for heating, and raise the temperature of the tungsten boat to 1000 °C within 5 minutes. The heating process is fast first and then slow;

[0026] 5) After holding at 1000 °C for 30 minutes, reduce the evaporation current to 0 A within 5 minutes, turn off the evaporation power supply, and cool the sample to room temperature naturally;

[0027] 6) Finally, put the sample into the annealing fu...

Embodiment 2

[0030] 1) Quartz slices (20*20 mm 2 ) ultrasonic cleaning in alcohol and deionized water for 15 min, and then drying at 110 °C;

[0031] 2) Weigh 0.7904 g tungsten powder and 0.0103 g europium oxide powder respectively, mix and grind them for 10 min, spread them evenly in a tungsten boat, place a dried quartz substrate on the tungsten boat, the distance between the tungsten boat and the substrate is 30 mm ;

[0032] 3) Vacuumize the chamber. When the vacuum degree is 1.0 Pa, feed Ar 100 sccm and stabilize for 10 min;

[0033] 4) Turn on the evaporation current for heating, and raise the temperature of the tungsten boat to 1200 °C within 10 minutes. The heating process is fast at first and then slow;

[0034] 5) After holding at 1200 °C for 60 minutes, reduce the evaporation current to 0 A within 15 minutes, turn off the evaporation power supply, and cool the sample to room temperature naturally;

[0035] 6) Finally, put the sample into an annealing furnace and anneal at 550...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com