Once-through boiler corrosion and scaling risk diagnosis method

A technology of once-through boiler and diagnosis method, which is applied in the direction of boiler working condition indication, etc., can solve problems such as boiler system corrosion, and achieve the effects of improving steam quality, reducing corrosion rate, and reducing the amount of deposits and scaling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Example 1 A diagnostic method for corrosion and scaling risks of once-through boilers

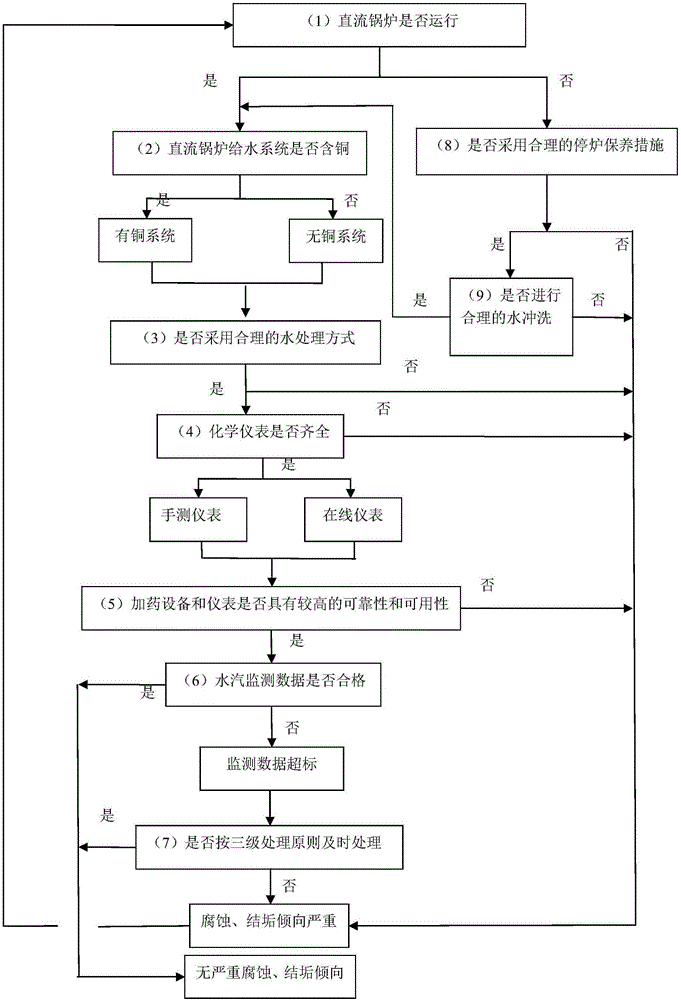

[0068] combine figure 1 The flowchart shown in the present invention describes the method of the present invention in detail. The first risk factor investigated by the diagnostic method of the present invention is (1) whether the once-through boiler is in operation. According to whether the once-through boiler is in operation, determine the boiler corrosion and scaling tendency judgment route.

[0069] Once through boiler is running

[0070] If the boiler is in operation, check the risk factors (2) Whether the once-through boiler water supply system contains copper alloy components (excluding condensers), and thus divide the water supply system into a copper system and a copper-free system. (3) Whether a reasonable water treatment method is adopted. The feed water treatment method adopted by the copper-free once-through boiler is full-volatility treatment, including reductive f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com