Shii-take sauce processing method

A processing method and the technology of mushroom sauce, which are applied in the field of mushroom processing, can solve the problems that mushrooms are easy to deteriorate, change taste, increase cost burden, etc., and achieve the effect of pure and delicious taste and not easy to deteriorate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

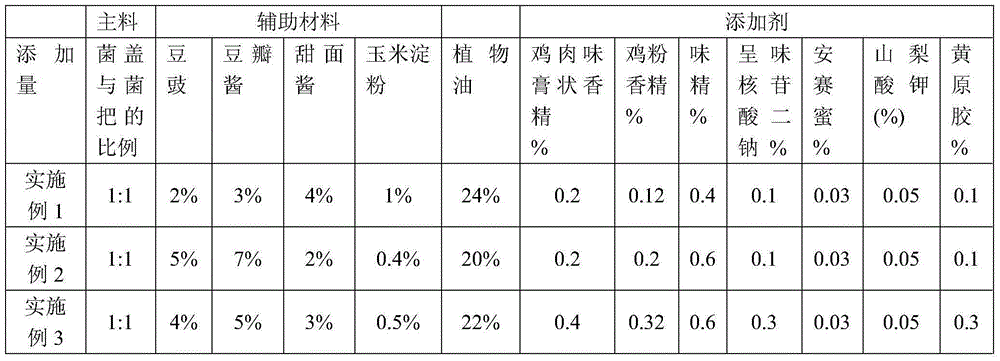

Embodiment 1 and 2 and 3

[0026] A processing method of shiitake mushroom paste, carried out according to the following steps:

[0027] a. Select materials, select main ingredients and auxiliary materials, the main ingredients are dried shiitake mushrooms, soak the dried shiitake mushrooms in cold water first, and then clean them; the auxiliary materials are composed of tempeh, bean paste, sweet noodle sauce and cornstarch.

[0028] b. Salting: Squeeze the shiitake mushrooms to remove water and cut into cubes, then add salt and salt for 3 hours. The amount of salt added is 3% of the weight of the shiitake mushrooms.

[0029] c. Stir-frying with ingredients, adding auxiliary materials and additives to shiitake mushrooms, stirring evenly, adding them to a frying pan with vegetable oil for frying, frying temperature ≥ 90°C, and frying time 20 minutes. ; The additive is composed of chicken flavor paste flavor, chicken powder flavor, monosodium glutamate, taste nucleotide disodium, acesulfame potassium, pot...

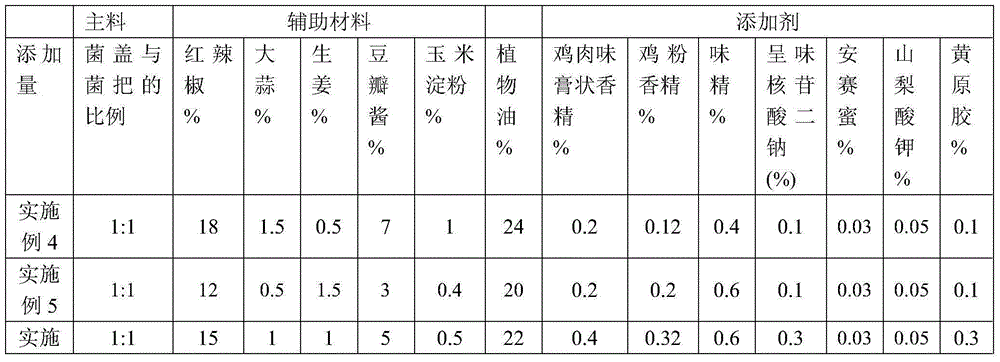

Embodiment 4 and 5 and 6

[0034] A processing method of shiitake mushroom paste, carried out according to the following steps:

[0035] a, optional materials, select main ingredients and auxiliary materials, the main ingredients are dried shiitake mushrooms, soak the dried shiitake mushrooms in cold water first, and then clean them; the auxiliary materials are red pepper, garlic, ginger, bean paste and cornstarch composition.

[0036] b, salting, the shiitake mushrooms are squeezed to remove water and cut into cubes, then salt is added for 2 hours, and the amount of salt added is 8% of the weight of the shiitake mushrooms;

[0037] c. Stir-frying with ingredients, adding auxiliary materials and additives to shiitake mushrooms, stirring evenly, adding them to a frying pan with vegetable oil for frying, frying temperature ≥ 90°C, and frying time 20 minutes. ; The additive is composed of chicken flavor paste essence, chicken powder essence, monosodium glutamate, taste nucleotide disodium, acesulfame pota...

Embodiment 7 and 8 and 9

[0043] A processing method of shiitake mushroom paste, carried out according to the following steps:

[0044] a, optional materials, select main ingredients and auxiliary materials, the main ingredients are dried shiitake mushrooms, first soak the dried shiitake mushrooms in cold water, and then clean them up; the auxiliary materials are composed of kohlrabi, pickled mustard, red pepper, garlic, ginger and corn Starch composition.

[0045] b. Salting: Squeeze the shiitake mushrooms to remove water, cut them into cubes, and then add salt to salt them for 2.5 hours. The amount of salt added is 4% of the weight of the shiitake mushrooms.

[0046] c. Stir-frying with ingredients, adding auxiliary materials and additives to shiitake mushrooms, stirring evenly, adding them to a frying pan with vegetable oil for frying, frying temperature ≥ 90°C, and frying time 20 minutes. ; The additive is composed of chicken flavor paste flavor, chicken powder flavor, monosodium glutamate, taste ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com