Carbonated water and manufacturing method thereof

A manufacturing method, carbonated water technology, applied in food preparation, preparation of alcoholic beverages, food science, etc., can solve problems such as not mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

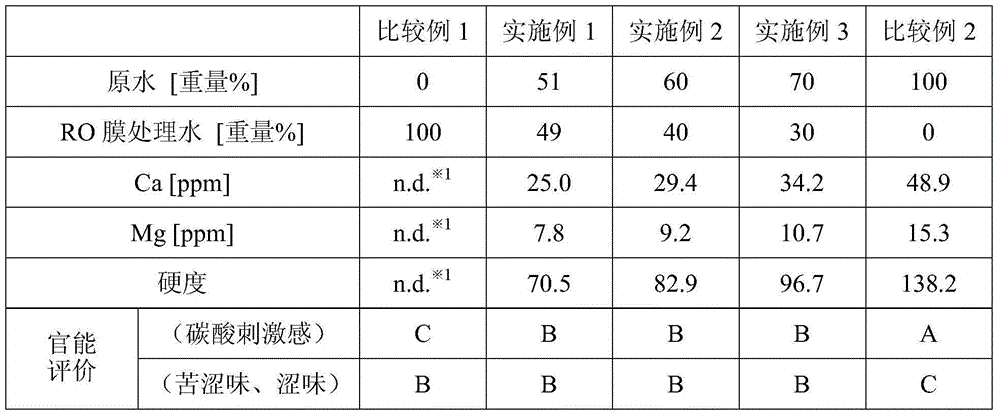

[0058] Examples 1-3, Comparative Examples 1-2

[0059] Mix RO membrane treated water and raw water according to the ratio described in Table 1, and press in carbon dioxide according to the usual press-in method to prepare carbonated water. The method of evaluating the mouthfeel of the obtained carbonated water by a sensory test was evaluated as follows, and the results are shown in Table 1.

[0060] The hardness in the raw water in this embodiment is the total hardness obtained through the determination method of 4.9 total hardness in the national standard GB / T8538-2008 detection method of drinking natural mineral water.

[0061] In this example, the content of calcium in the carbonated water was determined by the 4.13.1 disodium edetate titration method of 4.13 calcium in the national standard GB / T8538-2008 detection method for drinking natural mineral water.

[0062] In this example, the content of magnesium in the carbonated water is determined by the 4.14.1 disodium edeta...

Embodiment 4

[0090] Mix 45ml of the carbonated water of Example 2 and 135ml of whiskey with an alcohol content of 40 degrees to obtain wine containing carbonic acid gas.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com