Method for removing water in hydrogen fluoride by reactive distillation

A technology of reactive distillation and hydrogen fluoride, which is applied in the fields of fluorine/hydrogen fluoride, chemical industry, climate sustainability, etc. It can solve the problems of difficult separation of impurities, high operation risk, and low water removal efficiency, and achieve safe operation and simple process , High water removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

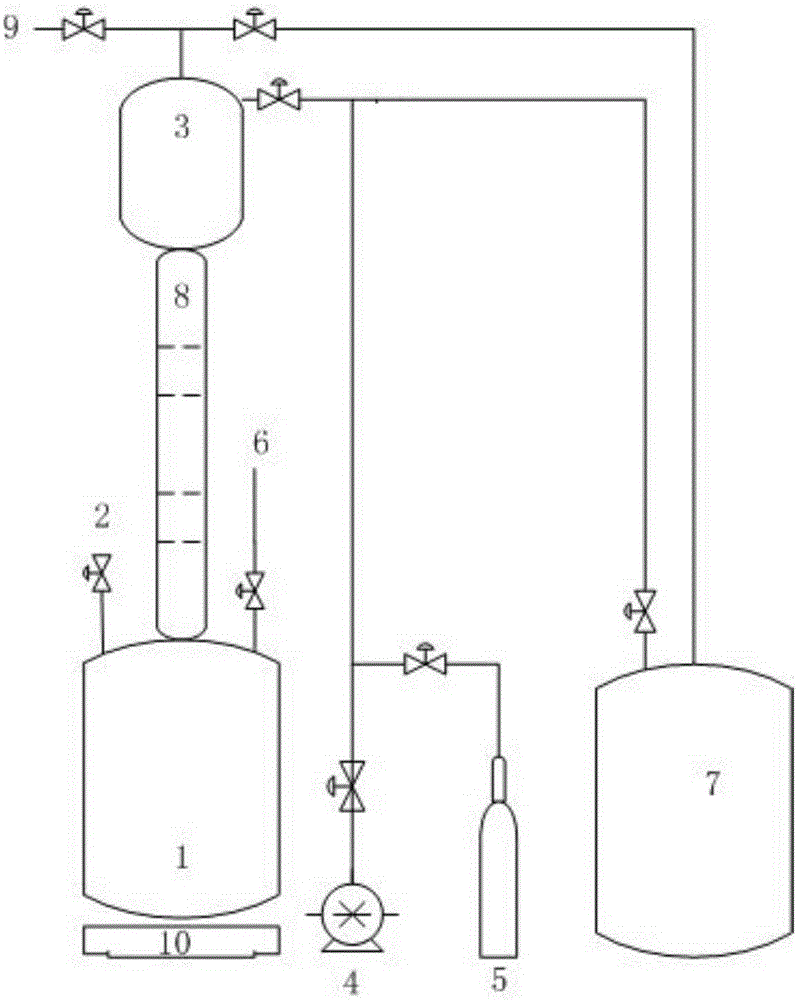

[0028] Add 1 kg of tungsten tetrafluoride with a diameter of 0.1mm into the reaction kettle 1 through the feed port I2, vacuumize the entire reaction device with a vacuum pump 4, and use the helium in the helium cylinder 5 for purging, and repeat for 10 Vacuum replacement treatment. Then, 100 kg of liquefied hydrogen fluoride was fed into the reactor 1 through the feed port II6. Utilize heating furnace 10 to heat reactor 1, utilize condenser 3 to lower the temperature, make the temperature difference between reactor 1 and condenser 3 be 5~10 ℃, pressure difference be 0.01~0.02MPa, the rectifying tower The water removal rectification temperature is controlled at 60-80°C for rectification. Take out a small amount of hydrogen fluoride from the condenser 3 through the sampling port 9 for analysis. When the water content in the hydrogen fluoride drops below 1ppm, adjust the rectification collection temperature of the rectification tower to 20-30°C and maintain a pressure differenc...

Embodiment 2

[0030] Add 1 kg of tungsten tetrafluoride with a diameter of 1 mm into the reaction kettle 1 through the feed port I2, vacuumize the entire reaction device with the vacuum pump 4, and use the helium in the helium cylinder 5 to purge, repeat 10 times Vacuum replacement treatment. Then, 800 kg of liquefied hydrogen fluoride was added into the reactor 1 through the feed port II6. Utilize heating furnace 10 to heat reactor 1, utilize condenser 3 to lower the temperature, make the temperature difference between reactor 1 and condenser 3 be 5~10 ℃, pressure difference be 0.01~0.02MPa, the rectifying tower The water removal rectification temperature is controlled at 80-100°C for rectification. Take out a small amount of hydrogen fluoride from the condenser 3 through the sampling port 9 for analysis. When the water content in the hydrogen fluoride drops below 1ppm, adjust the rectification collection temperature of the rectification tower to 30-40°C and maintain a pressure difference...

Embodiment 3

[0032] Add 0.5 kg of tungsten tetrafluoride with a diameter of 0.5 mm into the reaction kettle 1 through the feed port I2, vacuumize the entire reaction device with the vacuum pump 4, and use the helium in the helium cylinder 5 for purging, and repeat 10 vacuum replacement treatments. Then, 500 kg of liquefied hydrogen fluoride was fed into the reactor 1 through the feed port II6. Utilize heating furnace 10 to heat reactor 1, utilize condenser 3 to lower the temperature, make the temperature difference between reactor 1 and condenser 3 be 5~10 ℃, pressure difference be 0.01~0.02MPa, the rectifying tower The water removal rectification temperature is controlled at 70-90°C for rectification. Take out a small amount of hydrogen fluoride from the condenser 3 through the sampling port 9 for analysis. When the water content in the hydrogen fluoride drops below 1ppm, adjust the rectification collection temperature of the rectification tower to 25-35°C and maintain a pressure differe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com