High-temperature compost composition, high-temperature compost and preparation method thereof

A technology of high-temperature composting and composition, which is applied to the preparation of fertilizer mixtures, organic fertilizers, organic fertilizers, etc., can solve the problems of high preparation costs, impact on traffic safety, and complicated methods, so as to promote rapid reproduction, avoid limited sites, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of static high-temperature compost, which comprises the following steps:

[0031] 1) Stack 900 tons of wheat straw into haystacks with length, width and height of 150m, 6m and 3m respectively.

[0032] 2) Use a water pump to evenly inject 700 tons of water from the top of the haystack to ensure that the haystack is thoroughly watered from top to bottom.

[0033] 3) After 5 days, inject 300 tons of water evenly from the top of the haystack again, and evenly spray 30 tons of ammonium chloride, 2.5 tons of composite bacterial agents, and 30 tons of water on the top of the haystack. The composite bacterial agent is a mixture of Aspergillus niger, Penicillium, Trichoderma viride, Geobacillus stearothermophilus, and its weight ratio is 5:2:3:3; the total effective number of viable bacteria of the composite bacterial agent is 8× 10 8 individual / mL.

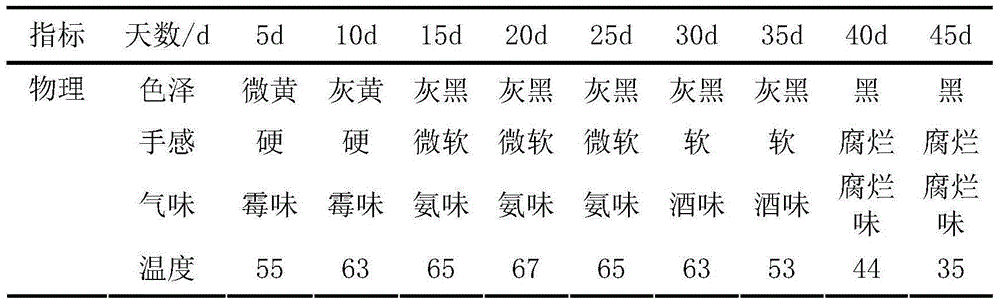

[0034] 4) Cover the haystack with a plastic sheet and compact it around, and make high-temperature compo...

Embodiment 2

[0041] A preparation method of static high-temperature compost, which comprises the following steps:

[0042] 1) Stack 1000 tons of wheat straw into haystacks with length, width and height of 200m, 6m and 4m respectively.

[0043] 2) Use a water pump to evenly inject 900 tons of water into the haystack from the top of the haystack to ensure that the haystack is thoroughly watered from top to bottom.

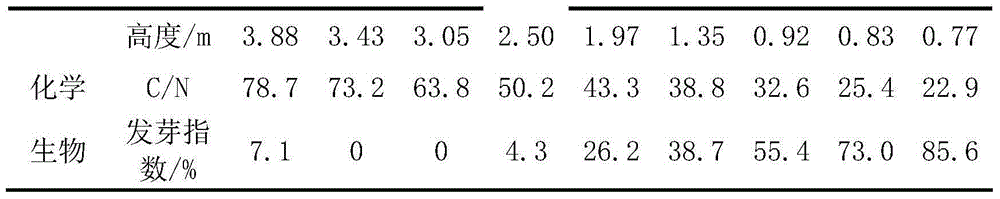

[0044]3) After 6 days, inject 350 tons of water evenly from the top of the haystack again, and evenly spray 7 tons of ammonium chloride, 7 tons of ammonium sulfate, 7 tons of ammonium bicarbonate, 3.5 tons of compound bacterial agents, and 50 tons of water system on the top of the haystack. The resulting aqueous solution. Described composite bacterial agent is the mixture of Trichoderma reesei, Trichoderma harzianum, Phanerochaete chrysosporium, Metarhizium anisopliae, and its weight ratio is 3:1:3:2; The total effective number of viable bacteria of described composite bacterial...

Embodiment 3

[0051] A preparation method of static high-temperature compost, which comprises the following steps:

[0052] 1) Pile 500 tons of wheat straw and 500 tons of corn straw together into several haystacks with length, width and height of 50m, 5m and 2.5m respectively. Wherein, the corn stalks are crushed to a length of about 4-7 cm before composting.

[0053] 2) Use a water pump to evenly inject 850 tons of water from the top of the haystack to ensure that the haystack is thoroughly watered from top to bottom.

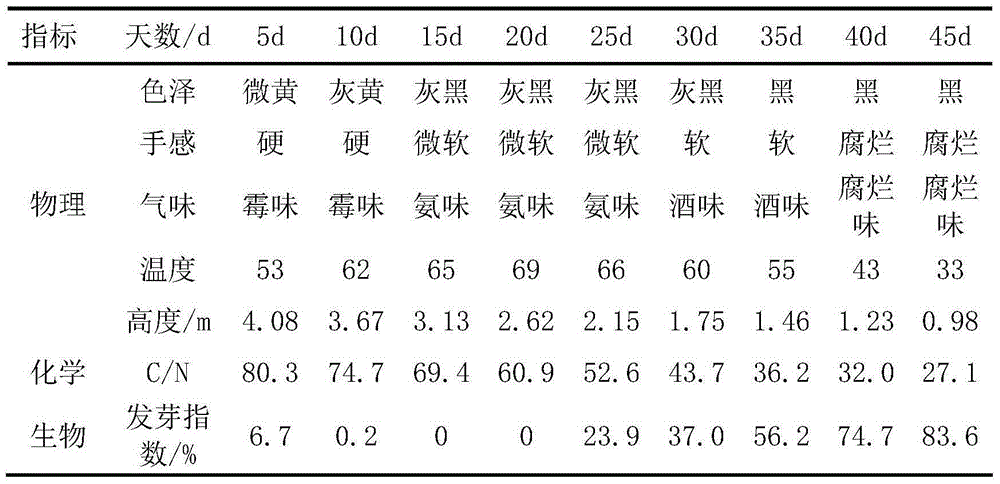

[0054] 3) After 6 days, inject 380 tons of water evenly from the top of the haystack again, and evenly spray 5 tons of urea, 5 tons of ammonium chloride, 12 tons of ammonium bicarbonate, 3 tons of compound bacterial agent, and 40 tons of water on the top of the haystack. of aqueous solution. Described composite bacterial agent is the mixture of Penicillium, Aspergillus oryzae, Trichoderma reesei, Pleurotus pellagra, Geobacillus stearothermophilus, Saccharomyces cerevisia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com