Method for preparing perylene bisimide nanometer fibers through one-step method

A peryleneimide and nanofiber technology is applied in the field of preparation of peryleneimide nanofibers, which can solve the problems of cumbersome preparation steps, complicated materials and high cost, and achieves cheap and easy-to-obtain raw materials, mild and environmentally friendly reaction conditions, and good dispersive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Prepare an ammonia solution with a mass concentration of 25%; add 20 mg of PTCDA to the prepared ammonia solution so that the mass ratio of PTCDA to ammonia in the ammonia solution is 1:50, and mix evenly; heat the mixed solution at 140°C for 12 hours under reflux, A perylene imide nanofiber solution is obtained; the solution is concentrated, filtered, washed, and freeze-dried to obtain a peryleneimide nanofiber solid.

[0025] The experimental result of embodiment 1 shows:

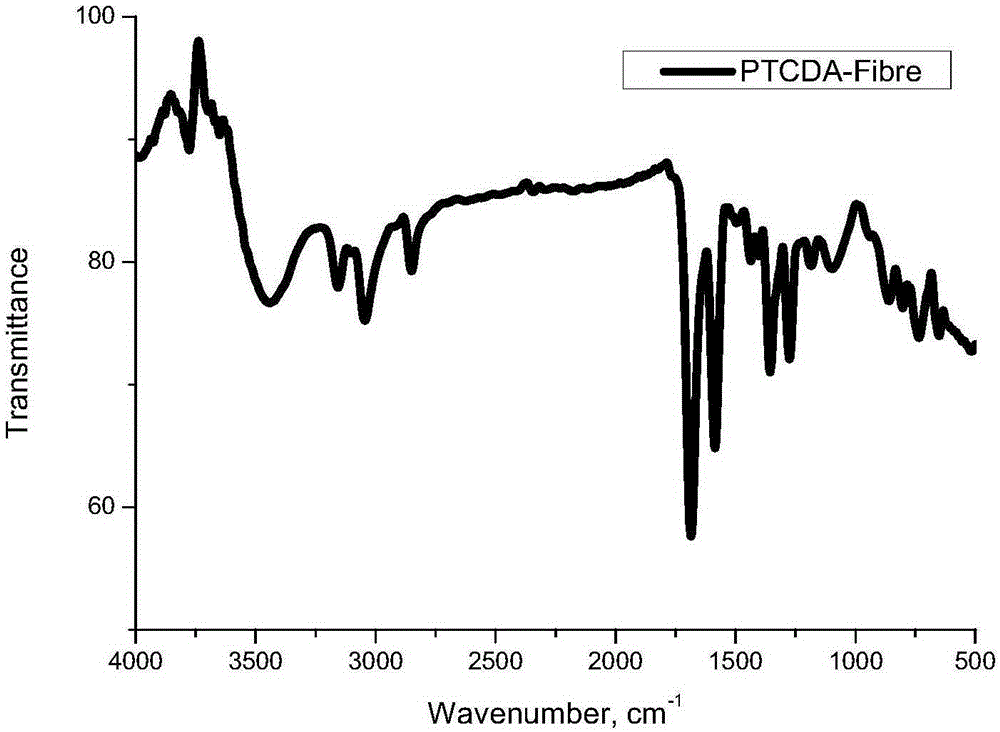

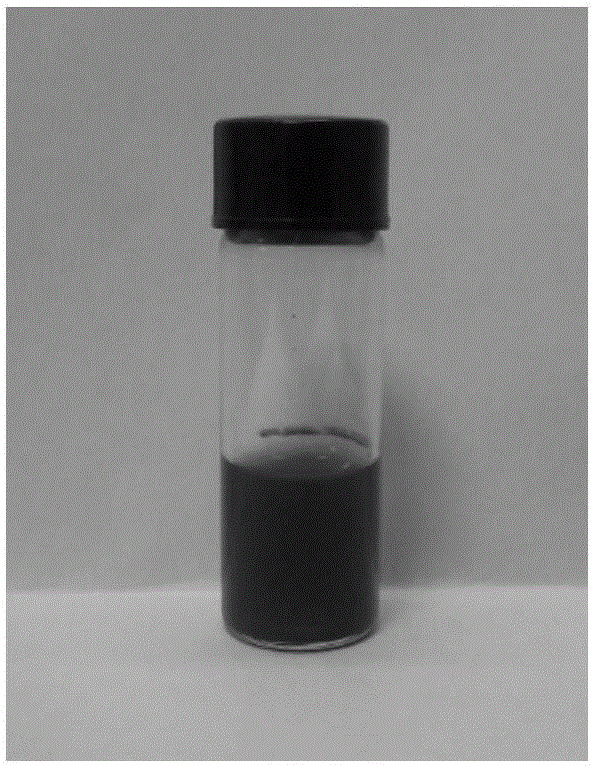

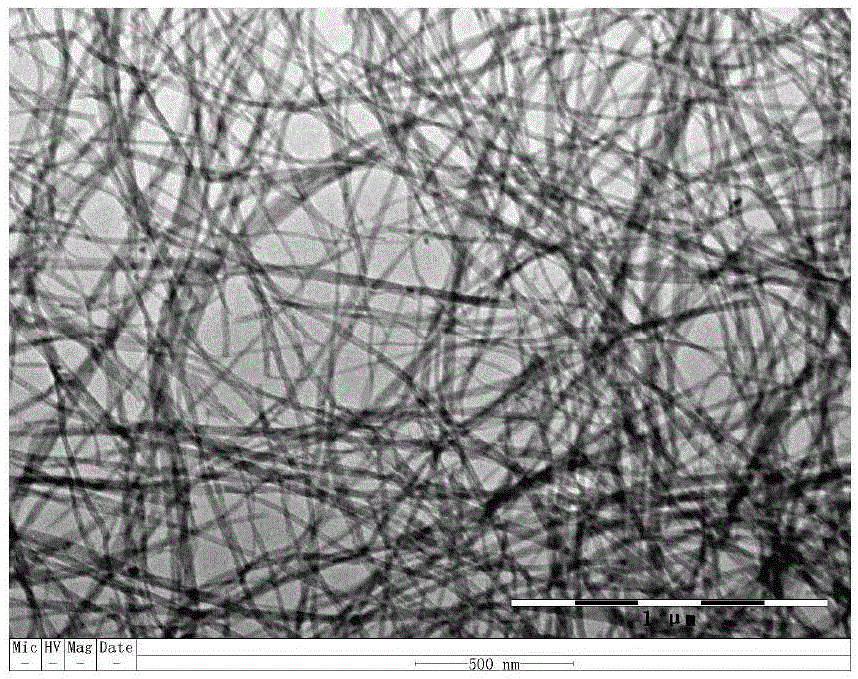

[0026] Such as figure 1 As shown, the experimental results are very close to the standard spectrum of perylene imide, in the figure 3400cm -1 There are obvious aromatic secondary amine peaks at 1700cm -1 There is a strong carbonyl peak at 1600cm -1 The left and right peaks are N-H bending vibration absorption peaks; dissolve the perylene imide nanofibers in water and wait for them to disperse evenly. Physical photos such as figure 2 As shown, the prepared peryleneimide nanofiber solution was ...

Embodiment 2

[0028] 10 groups of parallel experiments were designed, and the mass concentrations of the prepared ammonia solutions were 0.005%, 0.01%, 0.05%, 0.5%, 1%, 5%, 10%, 20%, and 25%, and all the other preparation methods were the same as in Example 1.

[0029] Table 1 Different ammonia solution concentrations make perylene imide nanofiber solid performance comparison table

[0030]

[0031] It can be seen from Table 1 that when the concentration of ammonia water is 0.01-25%, the morphology and dispersibility of the obtained peryleneimide nanofibers are good, and the higher the concentration of ammonia water, the better the morphology and dispersibility of the obtained nanofibers , the lower the concentration of ammonia water, the slightly worse morphology and dispersion performance of the obtained nanofibers.

Embodiment 3

[0033] Eight sets of parallel experiments were designed, and the mass ratios of PTCDA and ammonia were: (1:0.001), (1:0.005), (1:0.01), (1:0.1), (1:1), (1:10) , (1:20), (1:50), and all the other preparation methods are the same as in Example 1.

[0034] Table 2 Comparison table of solid properties of peryleneimide nanofibers prepared with different mass ratios of PTCDA and ammonia

[0035]

[0036] It can be seen from Table 2 that the higher the mass ratio of PTCDA to ammonia, the worse the solid morphology of the prepared peryleneimide nanofibers and the more large particles of impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com