A method for extracting rhenium

A reaction zone and roasting technology, which is applied in the field of extracting rhenium from rhenium-containing ore to extract rhenium by oxidizing and roasting, and extracting rhenium. Production efficiency, increase rhenium volatilization rate, and improve the effect of oxidation roasting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

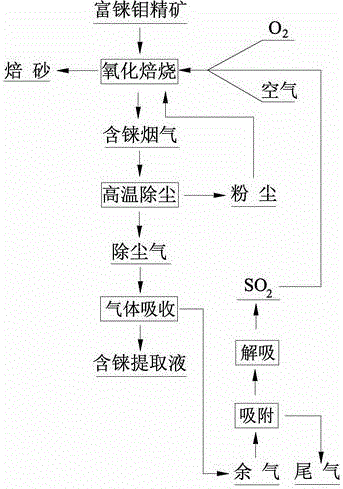

[0049] The method for extracting rhenium of the present invention, technological process such as figure 1 As shown, including the following process steps:

[0050] (1) Oxidation roasting of rhenium-containing ore

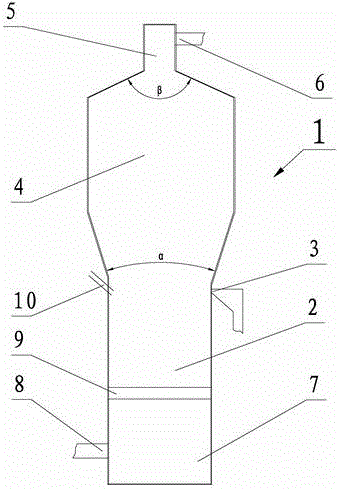

[0051] Send the rhenium-containing ore into the fluidized fluidized furnace, and contact with oxygen-containing air for roasting; the specific structure of the fluidized fluidized furnace is as follows: image 3 As shown, the lower part of the fluidized fluidized furnace is provided with a perforated gas distribution partition 9, that is, the furnace bottom. Below the furnace bottom is an air chamber 7 provided with an air inlet pipe 8. The air inlet pipe 8 is connected to the air supply system, and the furnace body 1 is upwards 1.0 along the furnace bottom At a height of ~1.5m, there are respectively a feed inlet 10 and a discharge outlet 3. The feed inlet 10 is slightly higher than the discharge outlet 3. The fluidized furnace body 1 is provided with a mixed reac...

Embodiment 2

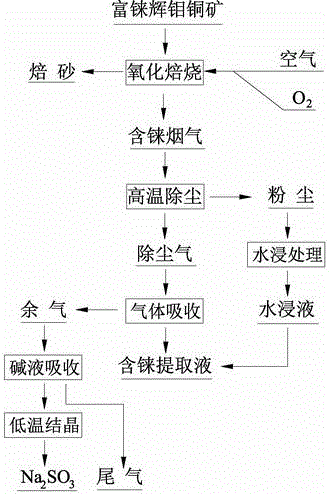

[0072] Using rhenium-rich molybdenite as raw material, the rhenium in the mineral is extracted by oxidizing and roasting. The rhenium content of the raw material is 530g / t. The process flow is as follows figure 2 As shown, including the following process steps:

[0073] (1) Oxidation roasting of rhenium-containing ore

[0074] Send the rhenium-containing ore raw materials into the fluidized fluidized furnace, and contact with oxygen-containing air for roasting; the specific structure of the fluidized fluidized furnace is as follows: image 3As shown, the fluidized furnace body 1 is provided with a mixed reaction zone 2 and a second reaction zone, the second reaction zone is higher than the discharge port 3 and is provided with an enlarged diameter section 4 and a reduced diameter section 5 along the furnace body 1 upwards. The diameter ratio of section 4 and mixing reaction zone 2 is 1.4:1, the junction of diameter expanding section 4 and mixing reaction zone 2 is in the sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com