Waterproof anti-reflection flexible OLED device and preparation method thereof

A device packaging and device technology, which is applied in the field of waterproof anti-reflection flexible OLED device and its preparation, can solve the problems of shortening OLED life, total reflection loss, deteriorating OLED stability and photoelectric parameter performance, etc., to increase waterproof effect, Overall thin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a preparation method for the above-mentioned OLED device, comprising the following steps:

[0041] (1) modify the surface of inorganic nanoparticles, such as Figure 4 shown in;

[0042] (2) Partially modified inorganic nanoparticles are dispersed in organic materials and degassed in a vacuum chamber; then the organic materials dispersed with inorganic nanoparticles are coated on the outside of the upper flexible substrate of the OLED device to form an anti-reflection layer ,Such as Figure 5 shown in;

[0043] (3) The exposure and development process is used to form a convex-concave microstructure on the surface of the anti-reflection layer, such as Figure 6 shown;

[0044] (4) The remaining inorganic nanoparticles in step (2) are deposited on the convex-concave surface of the anti-reflection layer by plasma-chemical vapor deposition, such as image 3 shown.

[0045] In the preparation method of the OLED device described in th...

Embodiment 1

[0051] Embodiment 1 A kind of OLED device

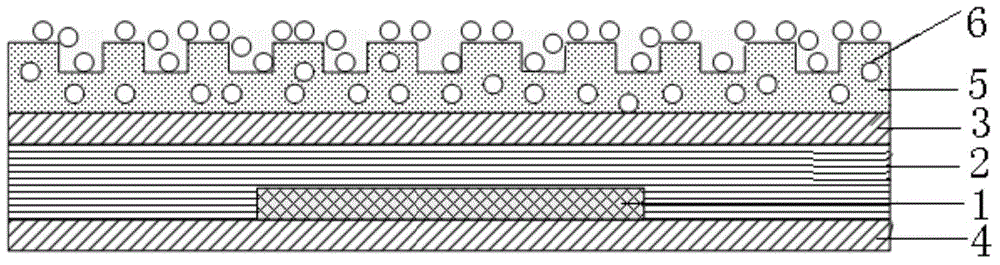

[0052] This embodiment provides an OLED device device, which is composed of an OLED device 1, a device encapsulation layer 2, an upper flexible substrate 3, and a lower flexible substrate 4; A layer of inorganic nanoparticles 6 is deposited on the surface of the layer.

[0053] Wherein, the surface of the anti-reflection layer is a convex-concave microstructure, and the film thickness is 2.6 microns; the anti-reflection layer is made of internally dispersed SiO 2 Nanoparticles are made of negative polyacrylate organic materials. Among them, the SiO 2 The molar ratio to the negative polyacrylate organic material is 8:1.

[0054] Wherein, the surface of the inorganic nanoparticles is modified by coupling agent KH550. Wherein, the mass of the coupling agent accounts for 2wt% of the total mass.

Embodiment 2

[0055] Embodiment 2 A kind of OLED device device

[0056] This embodiment provides an OLED device similar to Embodiment 1, the difference is:

[0057] 1) The anti-reflection layer is made of internally dispersed TiO 2 Nanoparticles made of organic silicone resin. Among them, the TiO 2 The molar ratio of organic material to silicone resin is 5:1.

[0058] 2) The surface of the inorganic nanoparticles is modified by coupling agent KH560. Wherein, the mass of the coupling agent accounts for 1 wt% of the total mass.

[0059] 3) The thickness of the anti-reflection layer is 2 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com