Method of manufacturing electrode applied to wearable device

A technology for electrode manufacturing and wearable devices, which is applied in the field of electrode manufacturing for wearable devices, can solve problems such as current sting, limited washing times, and short electrode life, so as to avoid current sting or burn, improve washing resistance, and reduce silver the lost effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

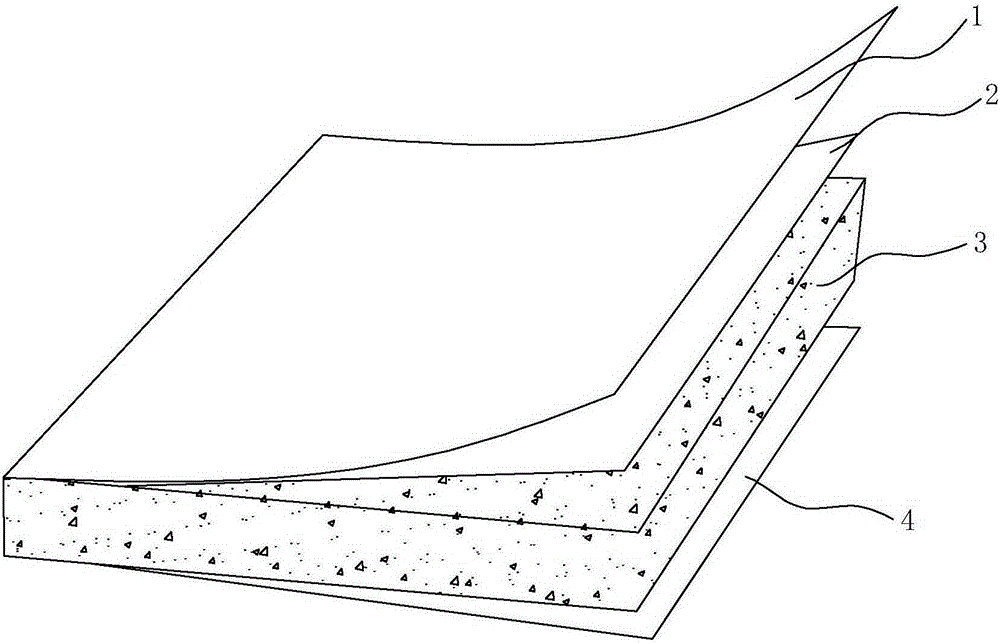

[0025] see figure 1 , an electrode applied to wearable devices, including silver-plated cloth 1, film 2, elastic layer 3 and base layer cloth 4 arranged in sequence to form an electrode, and the base layer cloth 4 is used for connection and fixing (usually by sewing) in the On the inner side of the clothing, the silver-plated cloth 1 fits the muscles of the human body.

[0026] The manufacturing method of above-mentioned electrode is:

[0027] 1) Making silver-plated cloth 1: In industrial applications, there are many types of conductive materials, mainly various metals, among which precious metals such as gold and silver have excellent electrical conductivity. Therefore, in the present invention, nylon fibers and spandex are selected for weaving Stretch fabrics (warp-knitted, weft-knitted or woven).

[0028] Preferably, superfine nylon fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com