Equipment and method for producing xanthate and recovering carbon disulfide from production tail gas

A carbon disulfide and xanthate technology, applied in the directions of carbon disulfide, chemical instruments and methods, separation methods, etc., can solve the slow industrialization process of xanthate synthesis technology, the disjointed research and production of xanthate, and the inability to achieve very good results. transformation and other problems, to achieve the effect of improving the level of synthesis technology, good environmental protection effect and good production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

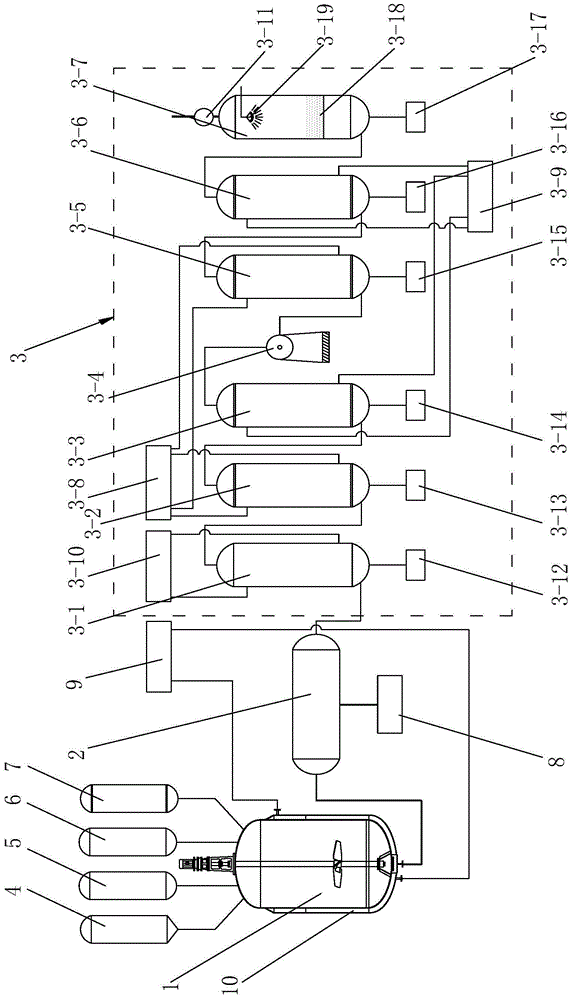

[0057] Such as figure 1 As shown, the equipment for producing xanthate and recovering carbon disulfide from the production tail gas in this embodiment includes a reactor 1, a rake dryer 2 and a carbon disulfide recovery system 3;

[0058] The top of described reactor 1 is provided with alkali feed inlet, alcohol feed inlet and carbon disulfide feed inlet, and the bottom of described reactor 1 is provided with discharge port, and described alkali feed inlet passes pipeline and alkali storage tank 4 is communicated, the alcohol feed port is communicated with the alcohol storage tank 5 through the pipeline, and the carbon disulfide feed port is communicated with the carbon disulfide storage tank 6 through the pipeline;

[0059] One end of the rake dryer 2 is provided with a feed inlet, the other end is provided with a tail gas outlet, and the bottom of the rake dryer 2 is provided with a discharge port; the discharge port of the reaction kettle 1 is connected to the The feeding ...

Embodiment 2

[0070] combine figure 1 , the present embodiment utilizes equipment as described in embodiment 1 to produce xanthate and the method for reclaiming carbon disulfide from production tail gas comprises the following steps:

[0071] Step 1, synthesis: Alcohol, alkali and carbon disulfide are added into reaction kettle 1 in molar ratio alcohol: alkali: carbon disulfide=1:1.02:6, then alcohol, alkali and carbon disulfide are reacted at a temperature of 30° C. for 7 hours to obtain Slurry; The alkali is sodium hydroxide, and the alcohol is Virahol;

[0072] Step 2, drying: add the slurry described in step 1 into the rake dryer 2, and dry it for 4 hours at a temperature of 75°C and a vacuum of -0.05MPa to obtain xanthate and production tail gas; Said xanthate is discharged into the xanthate collection tank 8 through the outlet of the rake dryer 2, and said production tail gas is discharged into the carbon disulfide recovery system 3 through the tail gas outlet of the rake dryer 2;

...

Embodiment 3

[0093] combine figure 1 , the present embodiment utilizes equipment as described in embodiment 1 to produce xanthate and the method for reclaiming carbon disulfide from production tail gas comprises the following steps:

[0094] Step 1, synthesis: Alcohol: base: carbon disulfide=1:1:5, add alcohol, base and carbon disulfide to reactor 1 in molar ratio, then react alcohol, base and carbon disulfide at a temperature of 40°C for 5h to obtain Slurry; The alkali is potassium hydroxide, and the alcohol is n-butanol;

[0095] Step 2, drying: add the slurry described in step 1 into the rake dryer 2, and dry it for 8 hours at a temperature of 65°C and a vacuum of -0.08MPa to obtain xanthate and production tail gas; Said xanthate is discharged into the xanthate collection tank 8 through the outlet of the rake dryer 2, and the production tail gas is discharged into the carbon disulfide recovery system 3 through the tail gas outlet of the rake dryer 2;

[0096] Step 3: Recovery of carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com