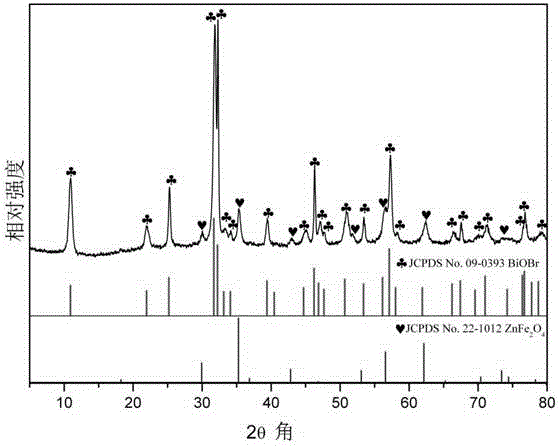

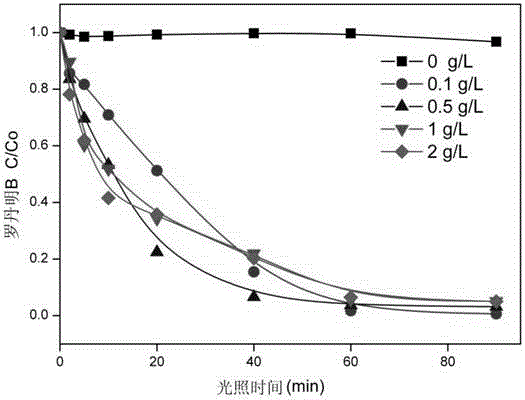

ZnFe2O4/BiOBr magnetic photocatalyst and preparation method thereof

A photocatalyst, znfe2o4 technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of secondary pollution, separation and recovery, human health and environmental hazards, and achieve low cost, Easy-to-control, actionable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A ZnFe 2 o 4 The preparation method of / BiOBr magnetic photocatalyst specifically comprises the following steps:

[0035] a. ZnCl 2 and FeCl 3 ·6H 2 O is dissolved in ethylene glycol solution with a molar ratio of 1:0.5-3, and stirred evenly to obtain solution A;

[0036] b. Add NaAc and polyethylene glycol to the solution A, stir evenly to obtain solution B;

[0037] c. Transfer the solution B to a reaction kettle, heat and react to obtain solution C and precipitate D;

[0038] d. Separate the solution C and the precipitate D, wash the precipitate D with ethanol, and dry it, the precipitate D is ZnFe 2 o 4 ;

[0039] e. Bi(NO 3 ) 3 ·5H 2 O and the precipitate D are dissolved in the acetic acid solution with a molar ratio of 1:0.6-1.2, and stirred evenly to obtain a solution E;

[0040] f. KBr is added to the solution E at a molar ratio twice that of the precipitate D, stirred evenly, and aged to obtain solution F and precipitate G;

[0041] g. Separate the ...

Embodiment 1

[0050] 2.5mmol of ZnCl 2 and 5 mmol FeCl 3 ·6H 2 O was dissolved in 40mL of ethylene glycol solution and stirred evenly to obtain solution A;

[0051] Weigh 3.6g of NaAc and 1.0g of polyethylene glycol 20000, pour them into the above solution A, and stir evenly, then mechanically stir the solution for 30min to obtain solution B;

[0052] Transfer the solution B to a 50mL reaction kettle, react at 200°C for 8 hours, separate the solution C and the precipitate D, wash the precipitate D with absolute ethanol 3 times, and dry it at 60°C for 6h, the obtained precipitate D is ZnFe 2 o 4 ,spare;

[0053] Weigh 2mmolZnFe 2 o 4 and 2mmol Bi(NO 3 ) 3 5H2O was ultrasonically dispersed into 100mL aqueous solution containing 5mL acetic acid, and stirred evenly at room temperature to obtain solution E;

[0054] Weigh 2mmol KBr, pour it into the above solution E, and stir evenly, then mechanically stir the solution for 60min, and age for 3h to obtain solution F and precipitate G; ...

Embodiment 2

[0058] 2.5mmol of ZnCl 2 and 1.25 mmol FeCl 3 ·6H 2 O was dissolved in 40mL of ethylene glycol solution and stirred evenly to obtain solution A;

[0059] Weigh 3.6g of NaAc and 1.0g of polyethylene glycol 20000, pour them into the above solution A, and stir evenly, then mechanically stir the solution for 30min to obtain solution B;

[0060] Transfer the solution B to a 50mL reaction kettle, react at 200°C for 8 hours, separate the solution C and the precipitate D, wash the precipitate D with absolute ethanol 3 times, and dry it at 60°C for 6h, the obtained precipitate D is ZnFe 2 o 4 ,spare;

[0061] Weigh 2mmolZnFe 2 o 4 and 2mmol Bi(NO 3 ) 3 ·5H 2 O was ultrasonically dispersed into 100 mL of aqueous solution containing 5 mL of acetic acid, and stirred evenly at room temperature to obtain solution E;

[0062] Weigh 2mmol KBr, pour it into the above solution E, and stir evenly, then mechanically stir the solution for 60min, and age for 3h to obtain solution F and p...

PUM

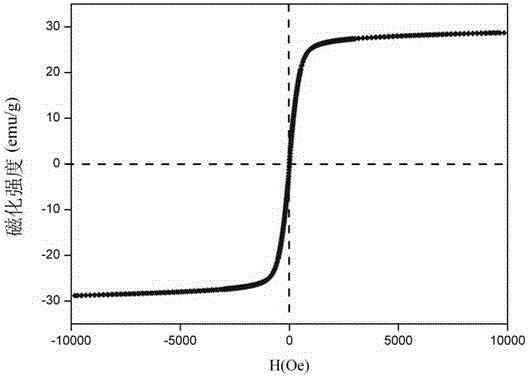

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com