Semi-wet electrostatic dust collector

An electrostatic precipitator, semi-wet technology, applied in the field of electrostatic precipitator, exhaust gas treatment and environmental protection, can solve the problems of noise, particle loss of charge, no obvious charge selectivity, etc., achieve high-efficiency capture, small air resistance, and reduce infection of influenza The effect of the risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

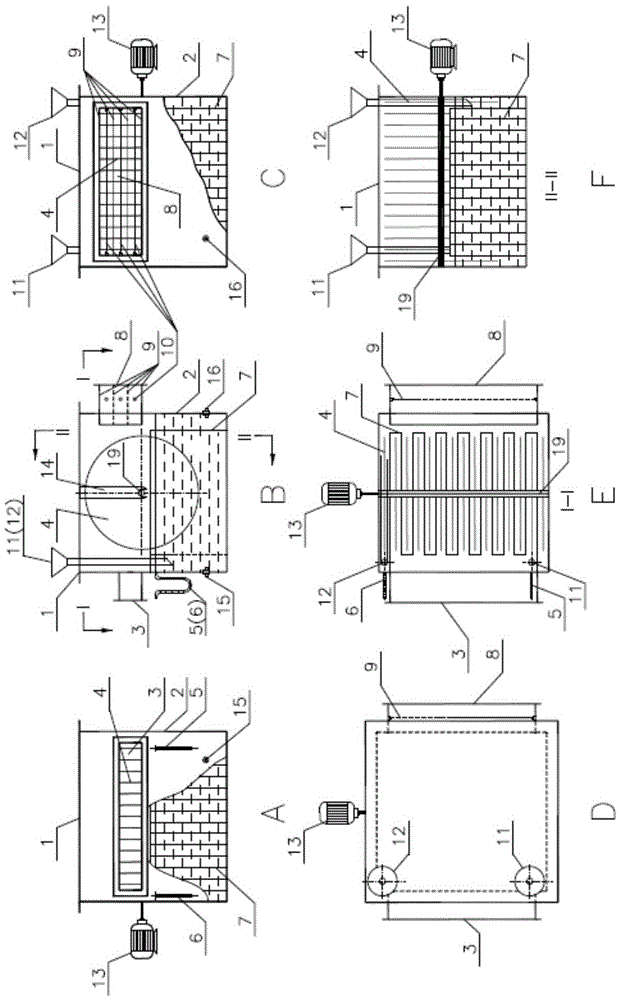

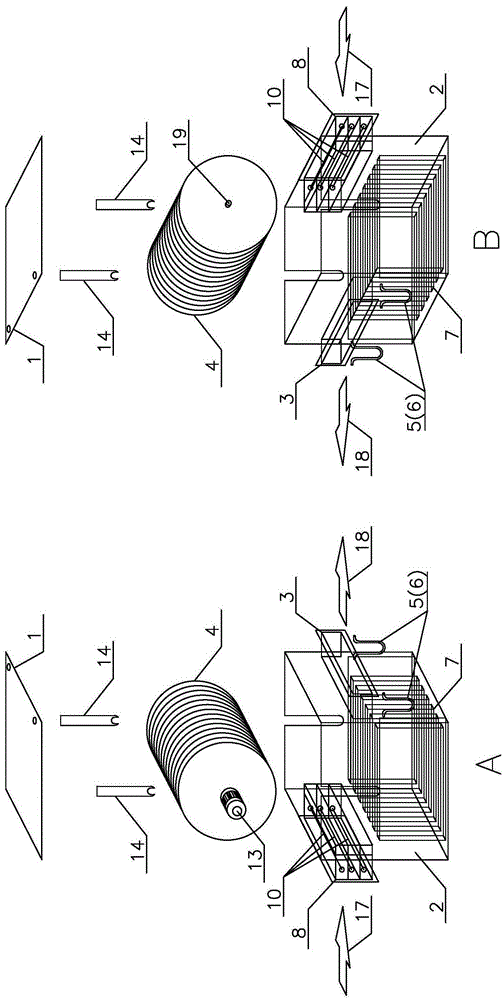

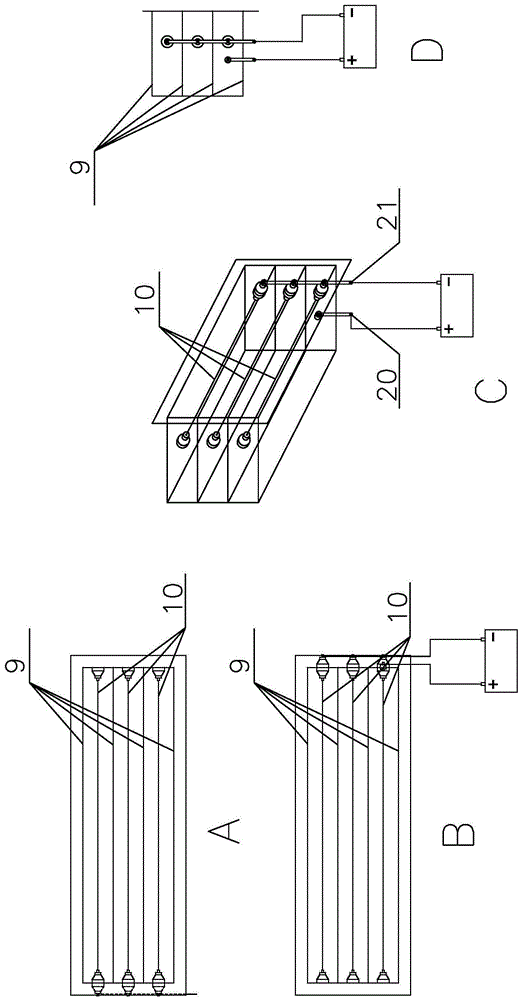

Embodiment 1

[0026] Three metal wires with a diameter of 0.2mm and a length of 20cm are used as corona electrodes, and they are placed between four dust collectors with a length of 20cm and a width of 8cm, and the technical supervision bureau is 2cm to make a pre-charged device. The corona electrodes are connected to a high-voltage power supply The positive electrode is set to 5000V, the dust collection plate is grounded, and placed at the air inlet of the dust collector. In the gas treatment box of the dust collector, take 10 pieces of aluminum discs with a diameter of 20cm as the disc dust collection poles, and fix them on the On a transmission shaft, the diameter of the transmission shaft is 1 cm, and the interval between each disc is 2 cm. Adjacent discs are placed in separate different liquid tanks. The liquid tanks are 0.5% benzalkonium bromide solution, and one of the liquid tanks is grounded. The other liquid tank is connected to the negative pole of the high-voltage power supply, t...

Embodiment 2

[0028] Take 12 star-shaped wires with a diameter of 0.1mm and a length of 5cm as corona electrodes, and place them on the center line of 12 metal cylinders with a diameter of 1cm parallel to the airflow direction and arranged in parallel. The pre-charging device, corona The pole is connected to the negative pole of the high-voltage power supply, set to 3000V, the dust collection plate is grounded, and placed at the air inlet of the dust collector. In the gas treatment box of the dust collector, take 15 pieces of phosphated steel discs with a diameter of 5cm as Disc-type dust collection pole, fixed on a transmission shaft, the diameter of the transmission shaft is 0.5cm, the distance between each disc is 0.8cm, and the adjacent discs are placed in different liquid tanks separated by 0.1% p-chlorine Ammonium xylenol solution, one of the liquid tanks is grounded, the other liquid tank is connected to the positive pole of the high-voltage power supply, and the voltage is 3000V. The...

Embodiment 3

[0030]A helical wire with a diameter of 1mm and a length of 20cm is used as a corona electrode, and is placed between two dust collecting electrodes with a length of 20cm and a width of 8cm, and the distance between the electrodes is 10cm to make a pre-charged device. The corona electrode is connected to the positive electrode of the high-voltage power supply , set to 20kV, the dust collector plate is grounded, placed at the air inlet of the dust collector, in the gas treatment box of the dust collector, take 20 hydrophilic modified PVC discs with a diameter of 30cm as the disc dust collector, Fixed on a transmission shaft, the diameter of the transmission shaft is 2cm, and the distance between each disc is 4cm. Adjacent discs are placed in separate different liquid tanks. The liquid tanks are 0.5% potassium sorbate solution, and one of the liquid tanks is grounded , the other liquid tank is connected to the negative pole of the high-voltage power supply, the voltage is 20kV, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com