Transparent polystyrene linear material for 3D printing and preparation method thereof

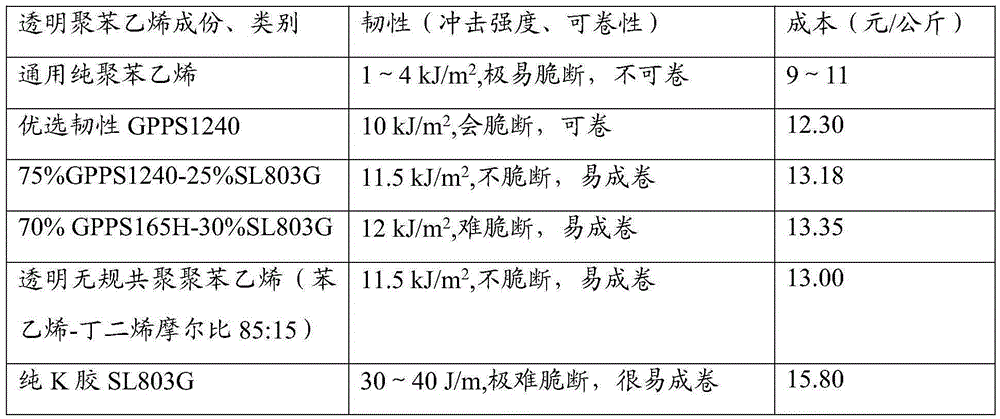

A transparent polystyrene and linear material technology, applied in the field of materials, can solve the problems of poor impact resistance, high rigidity, fragility and resistance to bending, etc., and achieve the effect of good fluidity, low cost and broad market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In this embodiment, a transparent polystyrene linear material for 3D printing is prepared as follows:

[0024] Use a balance scale to accurately weigh Total polystyrene GPPS-1240 10Kg, Maomingzhong and K glue (transparent styrene-butadiene random copolymer, wherein the molar percentage of butadiene is about 30%) SL- 803G2.5Kg, pre-disperse and compound after drying at 80°C, then melt compound at 230°C for 6 minutes in a twin-screw compound extrusion equipment, and then extrude in a circular die with a diameter of 1.75mm. The wire rod is cooled and shaped by the cooling water tank, pulled by the two-wheel tractor, wound on the duplex winder at a speed of 30m / min at a high speed, and finally dried to obtain the product.

Embodiment 2

[0026] In this embodiment, a transparent polystyrene linear material for 3D printing is prepared as follows:

[0027] Accurately Weigh Yangzi Petrochemical-BASF's PS Using a Balance Scale 165H10Kg, Maoming Zhonghe K glue SL-805F3.0Kg, pre-disperse and compound after drying at 100°C, then melt compound at 220°C for 8 minutes in a twin-screw compound extrusion equipment, and then in a diameter of 3.0mm Extruded in a circular die, the extruded wire is cooled and shaped in a cooling water tank, pulled by a two-wheel tractor, wound up on a duplex winder at a speed of 40m / min, and finally dried to obtain the product.

Embodiment 3

[0029] In this embodiment, a transparent polystyrene linear material for 3D printing is prepared as follows:

[0030] Accurately Weigh Yangzi Petrochemical-BASF's PS Using a Balance Scale 143E5Kg, GPPS-535N5Kg, Maomingzhonghe K glue SL-801G2.5Kg, pre-disperse and compound after drying at 80°C, then melt compound at 210°C for 10 minutes in a twin-screw compound extrusion equipment, and then in diameter It is extruded in a circular die with a diameter of 1.75mm. The extruded wire rod is cooled and shaped in a cooling water tank, pulled by a two-wheel tractor, and wound up on a duplex winder at a speed of 30m / min at a high speed, and finally dried.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com