Non-absorbent silkscreen printing ink for gold and sliver cards

A non-absorbent, gold-silver technology, which is applied in the field of non-absorbable gold and silver card screen printing ink and its preparation, can solve the problems of endangering human health, toxic gas, and polluting the environment, and achieve good adhesion, clean ink, and good The effect of suitability and gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

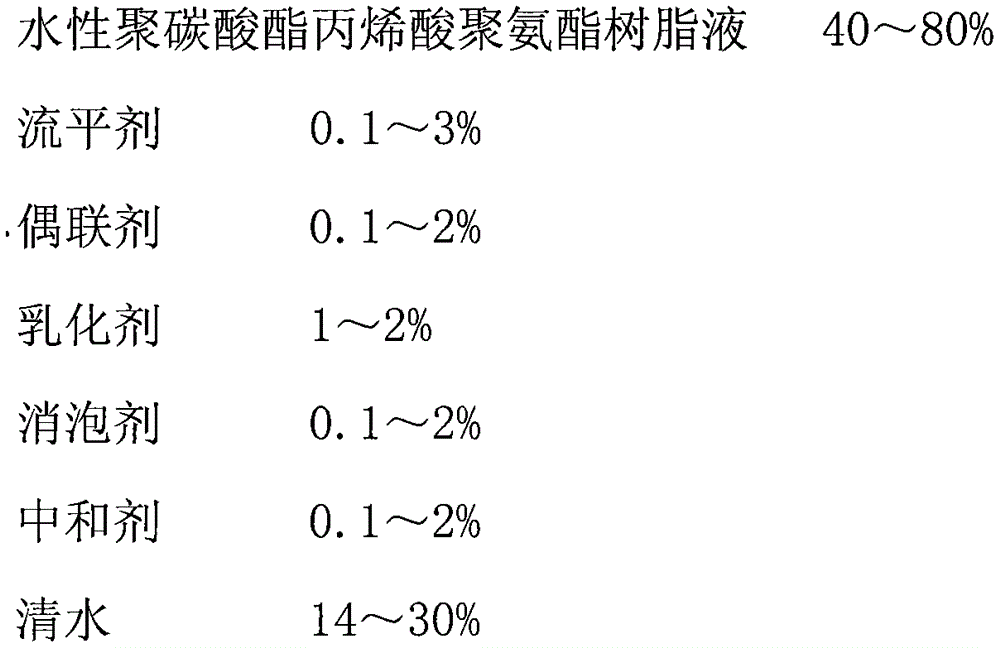

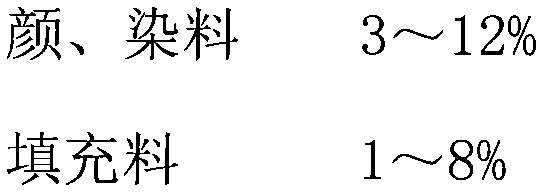

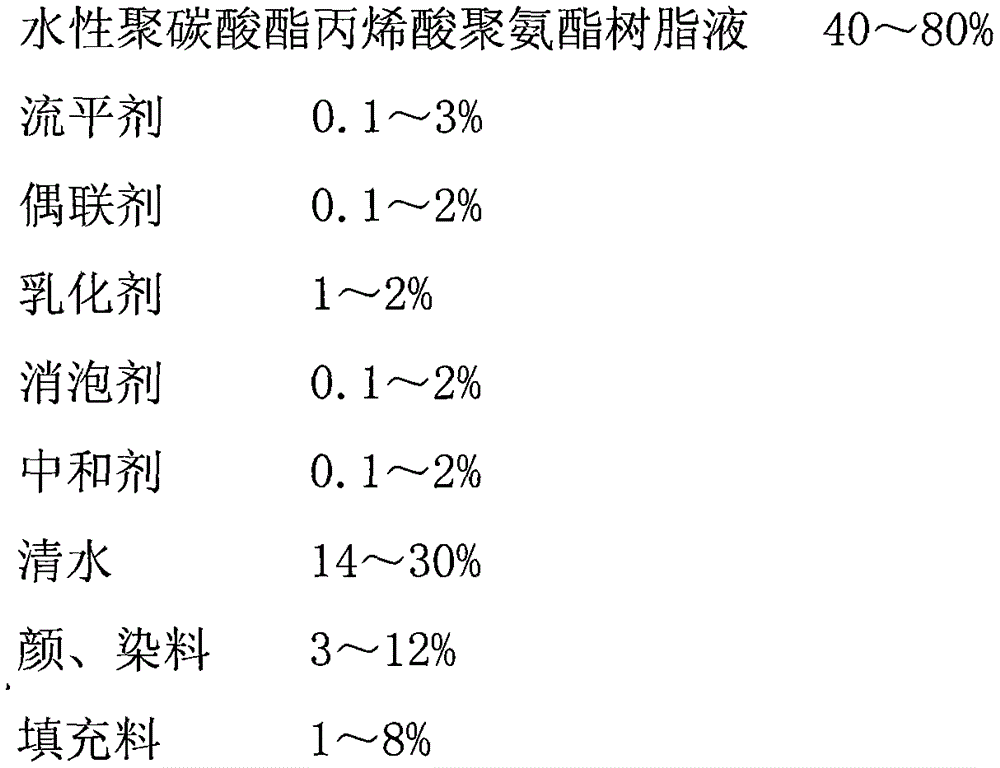

[0022] Formula weight percentage is as follows:

[0023] Water-based polycarbonate acrylic polyurethane resin solution 40Kg, accounting for 40%, leveling agent 3Kg, accounting for 3%, coupling agent 2Kg, accounting for 2%, emulsifier 2Kg, accounting for 2%, defoamer 2Kg, accounting for 2%, medium Blender 2Kg, accounting for 2%, clear water 30Kg, accounting for 30%, color, dyestuff 12Kg, accounting for 12%, filler 7Kg, accounting for 7%, the preparation method is as follows: Step 1, take water-based polycarbonate acrylic acid polyurethane resin liquid and put Put it into the container, add the neutralizing agent to adjust the pH value, and control the pH value to 6.6-8.0; step 2, take all the ingredients in the weight ratio of the formula and mix them evenly with step 1, and use a bead mill or a sand mill to grind it into a slurry; Step 3. Filter out impurities from the ground slurry to obtain finished ink.

[0024] The water-based polycarbonate acrylic polyurethane resin liqu...

Embodiment 2

[0033] Water-based polycarbonate acrylic polyurethane resin liquid 50Kg, accounting for 50%, leveling agent 2.5Kg, accounting for 2.5%, coupling agent 1.5Kg, accounting for 1.5%, emulsifier 2Kg, accounting for 2%, defoamer 1.5Kg, accounting for 1.5% %, neutralizing agent 1.5Kg, accounting for 1.5%, clear water 23Kg, accounting for 23%, color, dyestuff 10Kg, accounting for 10%, filler 8Kg, accounting for 8%, the preparation method is as follows: Step 1, water-based polycarbonate acrylic poly Put the ammonia resin liquid into the container, add the neutralizer to adjust the pH value, and control the pH value to 6.6-8.0; Step 2, take all the formula weight ratio ingredients and mix them evenly with Step 1, and use a bead mill or sand mill to grind It is a slurry; step 3, filtering out impurities from the ground slurry to obtain the finished ink.

[0034] The water-based polycarbonate acrylic polyurethane resin liquid in the formula is composed of 10-20% of polycarbonate, 15-30% o...

Embodiment 3

[0043] Water-based polycarbonate acrylic polyurethane resin solution 60Kg, accounting for 60%, leveling agent 2Kg, accounting for 2%, coupling agent 1Kg, accounting for 1%, emulsifier 1.5Kg, accounting for 1.5%, defoamer 1Kg, accounting for 1%, Neutralizer 1Kg accounts for 1%, clear water 20Kg accounts for 20%, color and dye 8.5Kg accounts for 8.5%, filler 5Kg accounts for 5%, and the preparation method is as follows: Step 1, take water-based polycarbonate acrylic polyurethane resin Put the liquid into the container, add the neutralizer to adjust the pH value, and control the pH value to 6.6-8.0; Step 2, take all the formula weight ratio ingredients and mix them evenly with Step 1, and use a bead mill or a sand mill to grind it into a slurry material; step 3, filtering out impurities from the ground slurry to obtain finished ink.

[0044] The water-based polycarbonate acrylic polyurethane resin liquid in the formula is composed of 10-20% of polycarbonate, 15-30% of acrylic res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com