Clean self-thermogenesis pressurization reservoir reconstruction liquid and preparation method thereof

A technology for reservoir reconstruction and self-generating heat, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of lagging and unsatisfactory effects after compaction, and achieve convenient operation, simple preparation method, and good sand-carrying performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

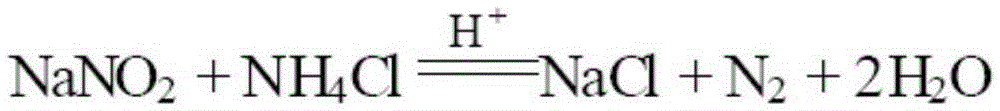

Problems solved by technology

Method used

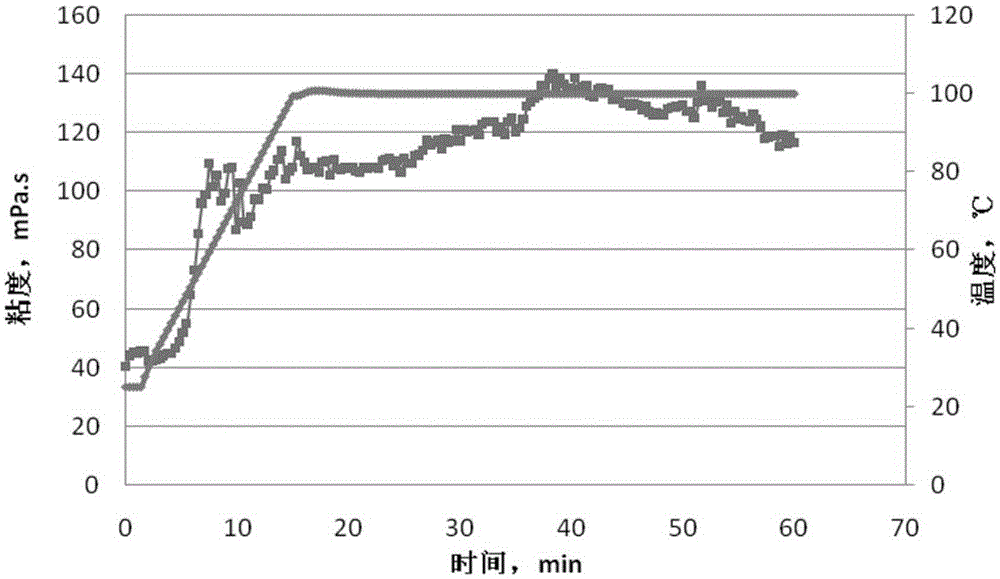

Image

Examples

Embodiment 1

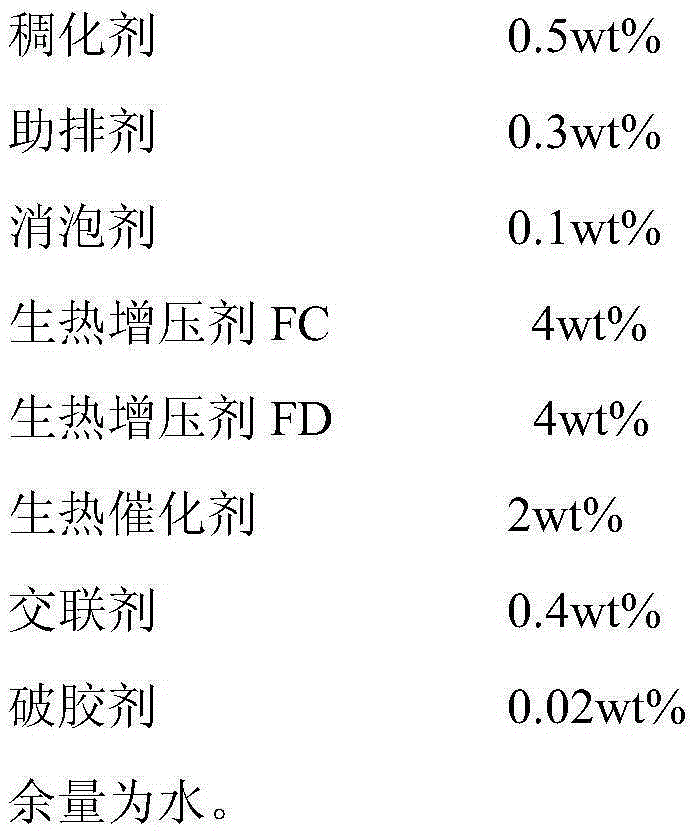

[0033] This embodiment provides a clean self-generating heat pressurized reservoir reforming fluid, based on the total mass of the clean self-generating heat pressurized reservoir reforming fluid as 100%, the raw material of the clean self-generating heat pressurized reservoir reforming fluid Composition includes:

[0034]

[0035] Wherein, the thickening agent is hydrophobic polyacrylamide (polymerization degree 16000), the drainage aid is drainage aid DL-8, the defoamer is nonylphenol polyoxyethylene ether, and the solid acid included in the heat generating catalyst is citric acid, The breaker is ammonium persulfate, the heat-generating booster FC is ammonium chloride, and the heat-generating booster FD is sodium nitrate.

[0036] This embodiment also provides a method for preparing the above-mentioned clean self-generating heat pressurized reservoir reforming fluid, which specifically includes the following steps:

[0037] In the state of stirring, add heat-generating s...

Embodiment 2

[0039] This embodiment provides a clean self-generating heat pressurized reservoir reforming fluid, based on the total mass of the clean self-generating heat pressurized reservoir reforming fluid as 100%, the raw material of the clean self-generating heat pressurized reservoir reforming fluid Composition includes:

[0040]

[0041] Among them, the thickener is hydrophobic polyacrylamide (the degree of polymerization is 16000), the drainage aid is DL-8, and the defoamer is alkyl Phenolic Resin Block polyether, the solid acid included in the heat-generating catalyst is ethylenediaminetetraacetic acid, the gel breaker is ammonium persulfate, the heat-generating booster FC is ammonium chloride, and the heat-generating booster FD is sodium nitrate.

[0042] This embodiment also provides a method for preparing the above-mentioned clean self-generating heat pressurized reservoir reforming fluid, which specifically includes the following steps:

[0043] In the state of stirring, ...

Embodiment 3

[0045] This embodiment provides a clean self-generating heat pressurized reservoir reforming fluid, based on the total mass of the clean self-generating heat pressurized reservoir reforming fluid as 100%, the raw material of the clean self-generating heat pressurized reservoir reforming fluid Composition includes

[0046]

[0047] Among them, the thickener is hydrophobic polyacrylamide (the degree of polymerization is 16000), the drainage aid is DL-8, the defoamer is nonylphenol polyoxyethylene ether, the solid acid included in the heat generating catalyst is oxalic acid, and the gel breaker is sodium persulfate, the heat-generating supercharger FC is ammonium chloride, and the heat-generating supercharger FD is sodium nitrate.

[0048]This embodiment also provides a method for preparing the above-mentioned clean self-generating heat pressurized reservoir reforming fluid, which specifically includes the following steps:

[0049] In the state of stirring, add heat-generatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com