Multi-scale and double-state structure titanium alloy based on eutectic transformation, preparation and application

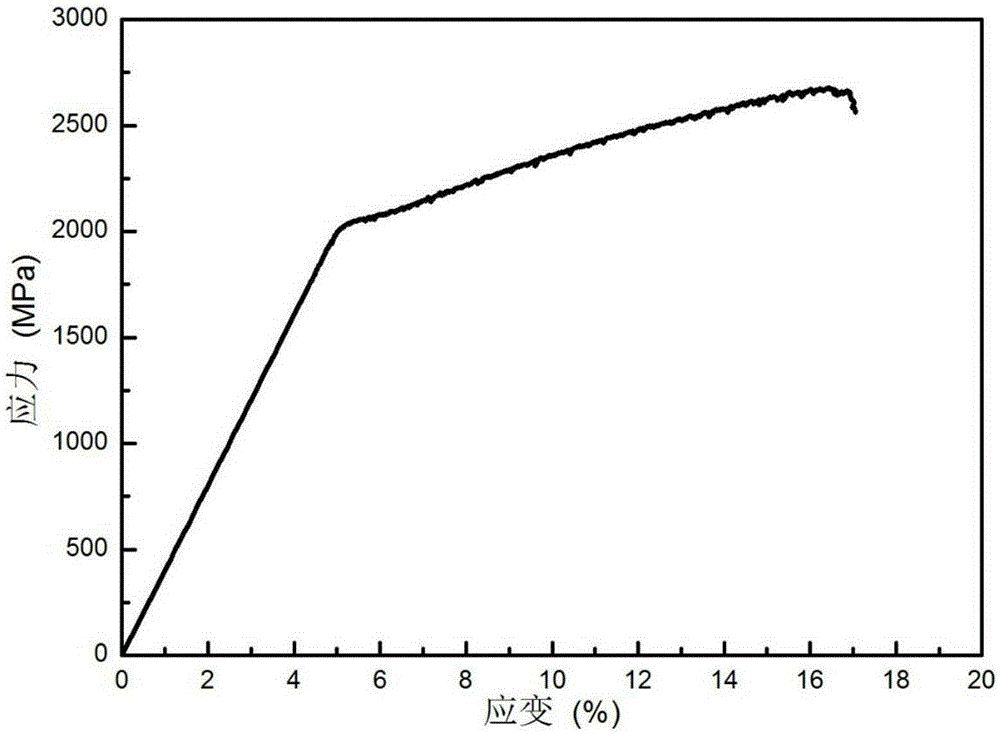

A dual-state structure and eutectic transformation technology, applied in the field of alloy processing, can solve the problems of coarse grains, complicated preparation procedures, and difficulty in obtaining ultra-fine grains, and achieve the effect of improving fracture strength and fracture strain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

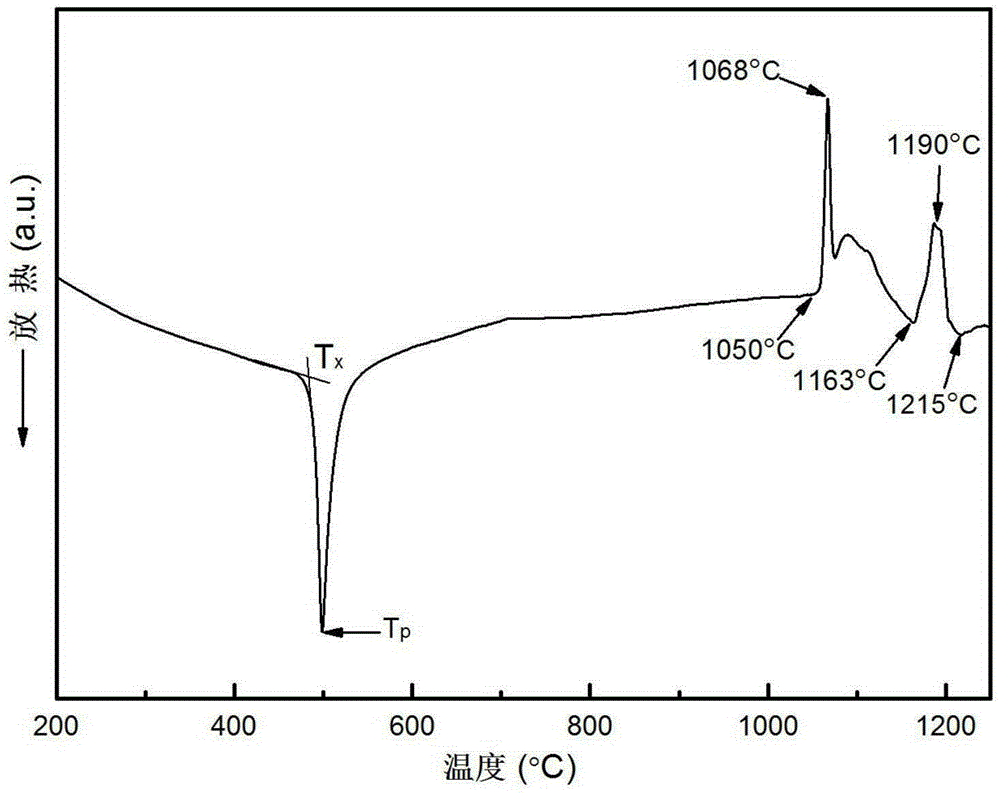

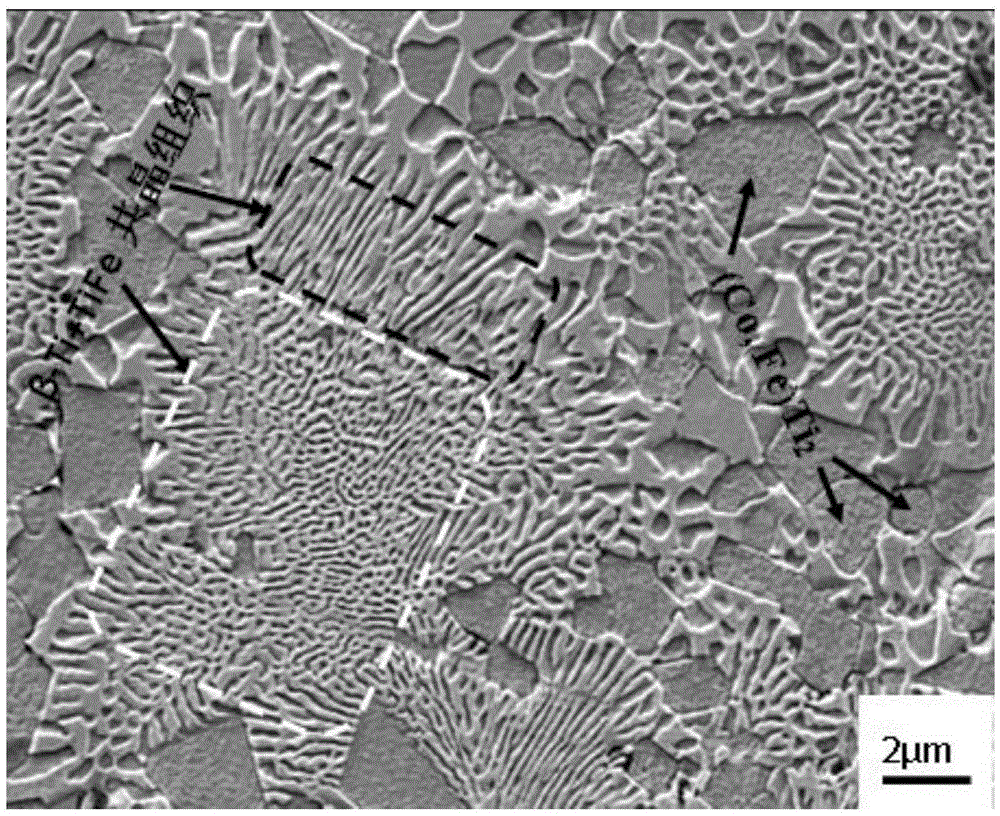

[0037] (1) Powder mixing: According to the material design principle that the alloy system has multiple crystalline phases, and two phases can preferentially undergo eutectic transformation, the designed alloy system is Ti 52.5 Nb 12.2 Fe 21.5 co 8 Al 5.8 (atomic percent), which includes bccβ-Ti, bccTiFe, and fccCoTi 2 and other three crystalline phases, among which bccβ-Ti and bccTiFe can preferentially undergo eutectic transformation to form a liquid phase, and the elemental powders of Ti, Nb, Fe, Co and Al elements with a particle size of 75 μm prepared by atomization method are calculated by atomic percentage For ingredients, mix the elemental powders in a mixer until they are evenly mixed.

[0038] (2) Preparation of alloy powder by high-energy ball milling: Place the uniformly mixed alloy powder in a planetary ball mill (QM-2SP20) for high-energy ball milling. The ball milling medium such as the tank body and ball material of the ball mill are all stainless steel, an...

Embodiment 2

[0046] (1) Powder mixing: According to the material design principle that the alloy system has multiple crystalline phases, and two phases can preferentially undergo eutectic transformation, the designed alloy system is Ti 62 Nb 14.1 Fe 5.5 co 11.7 Al 6.7 (atomic percent), which includes bccβ-Ti, bccTiFe, and fccCoTi 2 and other three crystalline phases, among which bccβ-Ti and bccTiFe can preferentially undergo eutectic transformation to form a liquid phase, and the elemental powders of Ti, Nb, Fe, Co and Al elements with a particle size of 150 μm prepared by atomization method are calculated by atomic percentage For ingredients, mix the elemental powders in a mixer until they are evenly mixed.

[0047] (2) Preparation of alloy powder by high-energy ball milling: Place the uniformly mixed alloy powder in a planetary ball mill (QM-2SP20) for high-energy ball milling. The ball milling medium such as the tank body and ball material of the ball mill are all stainless steel, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com