Stainless steel material modified through ruthenium complex and preparation method and application thereof

A technology of ruthenium complexes and stainless steel, which is applied in the field of stainless steel materials modified by ruthenium complexes and its preparation and application, can solve the problems of poor biocompatibility, toxicity, and failure of orthopedic surgery of stainless steel, so as to improve biocompatibility, improve Activity, effect of improving antibacterial and anticancer ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0033] A stainless steel material, the surface of the stainless steel material is modified with a ruthenium complex.

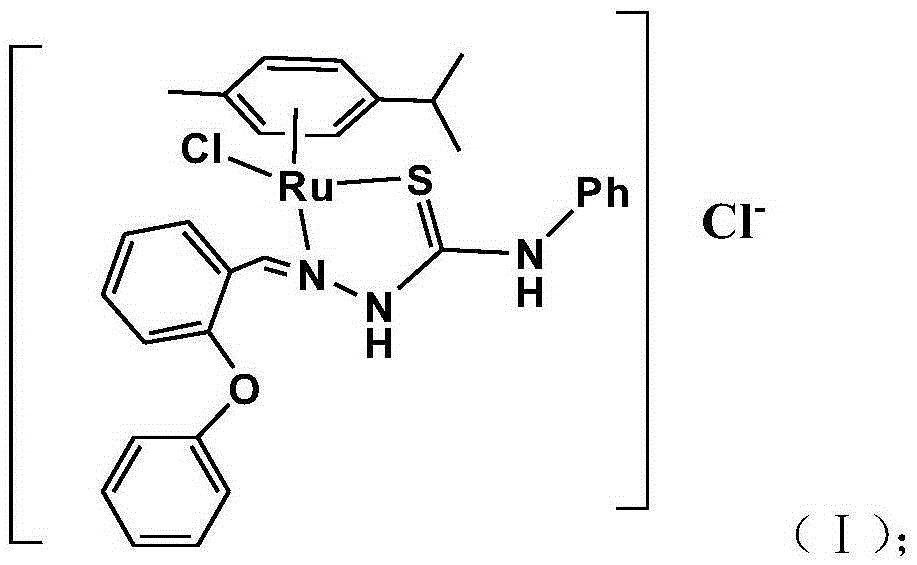

[0034] For the stainless steel material, the structural formula of the ruthenium complex is formula (I);

[0035]

[0036] The chemical name of the ruthenium complex is: monochloro-chloro-o-phenoxybenzene-2-condensed N 4 -Phenylthiosemicarbazide-cymene ruthenium, the molecular formula of the ruthenium complex is C 30 h 31 ON 3 SRuCl 2 , the relative molecular weight of the ruthenium complex is 618.178;

[0037] The physical and chemical properties of the ruthenium complex are: yellow crystals, easily soluble in organic solvents, and its hydrogen nuclear magnetic resonance spectrum data is 1 HNMR (CDCl 3 Solvent): δ: 8.857(1H, s), 8.522-8.375(7H, m), 7.516-7.433(7H, m), 5.733(1H, d, J=6.0Hz), 5.218(1H, d, J= 5.9Hz), 5.119(1H,d,J=6.0Hz), 5.018(1H,d,J=6.0Hz), 2.730-2.617(1H,m), 2.146(3H,s), 1.218(3H,d, J=6.9Hz), 1.165 (3H,d, J=6.9Hz).

[0038] The pre...

example 2

[0053] A stainless steel material, the surface of the stainless steel material is modified with a ruthenium complex.

[0054] For the stainless steel material, the structural formula of the ruthenium complex is formula (I);

[0055]

[0056] The chemical name of the ruthenium complex is: monochloro-chloro-o-phenoxybenzene-2-condensed N 4 -Phenylthiosemicarbazide-cymene ruthenium, the molecular formula of the ruthenium complex is C 30 h 31 ON 3 SRuCl 2 , the relative molecular weight of the ruthenium complex is 618.178.

[0057] The preparation method of described ruthenium complex comprises the following steps:

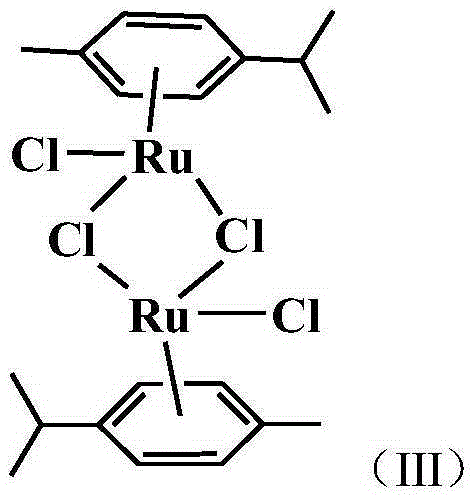

[0058] Step 1, 65 parts by weight of ruthenium trichloride hydrate and 470 parts by weight of gamma-terpinene were dissolved in 1450 parts by weight of dehydrated alcohol, heated to reflux and stirred for 5 hours, and left to separate out to obtain dichlorinated dichloro- Two-methylcumene diruthenium (II), its structural formula is formula (III)

[0059] ...

example 3

[0073] A stainless steel material, the surface of the stainless steel material is modified with a ruthenium complex.

[0074] The structural formula of the ruthenium complex is formula (I);

[0075]

[0076] The chemical name of the ruthenium complex is: monochloro-chloro-o-phenoxybenzene-2-condensed N 4 -Phenylthiosemicarbazide-cymene ruthenium, the molecular formula of the ruthenium complex is C 30 h 31 ON 3 SRuCl 2 , the relative molecular weight of the ruthenium complex is 618.178.

[0077] The preparation method of described ruthenium complex comprises the following steps:

[0078] Step 1. Dissolve 70 parts by weight of ruthenium trichloride hydrate and 480 parts by weight of gamma-terpinene in 1500 parts by weight of dehydrated alcohol, heat and reflux and stir for 7 hours, and leave to precipitate to obtain dichlorodichloro- Two-methylcumene diruthenium (II), its structural formula is formula (III)

[0079]

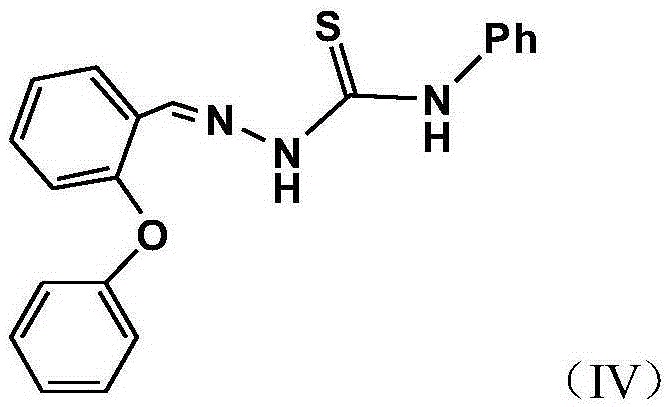

[0080] Step 2, take 35 parts by weight of N 4 -...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap