Inorganic fireproof thermal insulation plate and preparation method thereof

A fire-proof insulation board, inorganic technology, applied in the direction of heat preservation, fire prevention, chemical instruments and methods, etc., can solve the problems of high cost, pollute the environment, large water absorption, etc., achieve good heat insulation performance, stable chemical performance, improve resistance The effect of compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

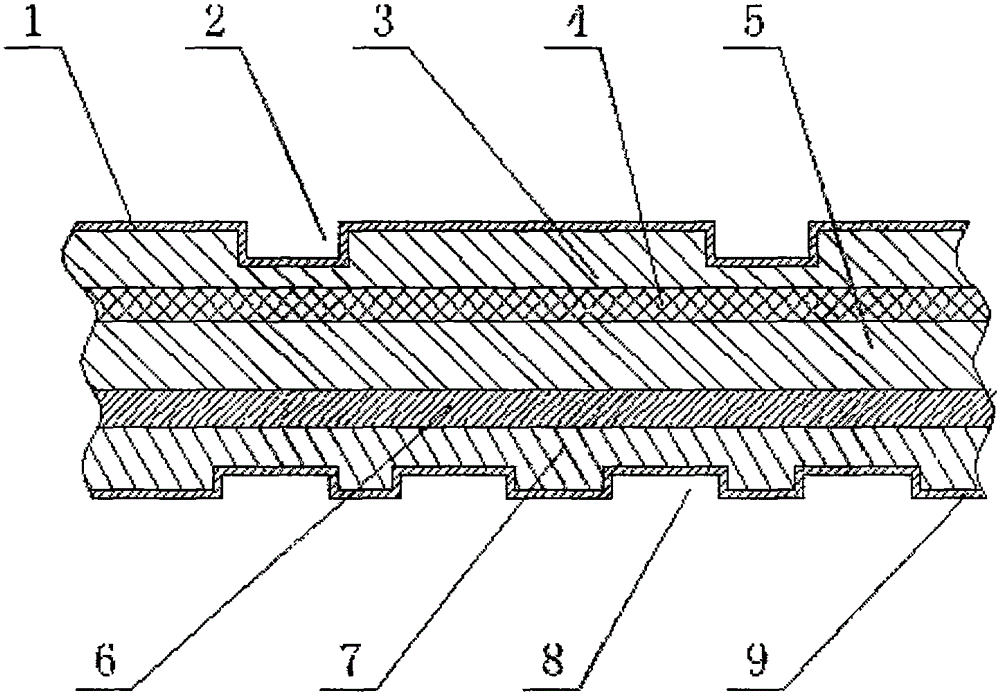

[0022] An inorganic fireproof insulation board, as shown in the accompanying drawings, from top to bottom is a hollow ceramic bead surface layer 3, a glass fiber mesh cloth layer 4, an expanded perlite composite layer 5, a glass fiber mesh cloth layer 6 and a hollow Ceramic bead bottom layer7.

[0023] Several pits 2 are arranged on the upper surface of the hollow ceramic bead surface layer 3 , and several grooves 8 are arranged on the outer surface of the hollow ceramic bead bottom layer 7 . In this embodiment, the purpose of the pits 2 is to fix the anchor during installation; the purpose of the grooves 8 is to prevent slippage when bonding the wall, and the arrangement is much denser than that of the pits 2 . The upper surface of the hollow ceramic bead surface layer 3 and the lower surface of the hollow ceramic bead bottom layer 7 are respectively provided with non-woven fabric layers 1 and 9 made of non-woven fabric. processed.

[0024] The hollow ceramic bead surface l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com