Preparation of α‑fe based on hydrothermal method 2 o 3 nanotube array method

A technology for nanotube arrays and nanorod arrays is applied in the field of preparing-Fe2O3 nanotube arrays based on a hydrothermal method, which can solve the problems of difficulty in assembling into ordered arrays, unfavorable large-scale production, complex and expensive use, etc., and achieves low equipment requirements. , The effect of low production cost and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation α-Fe provided by the present invention 2 o 3 The nanotube array approach has at least the following advantages:

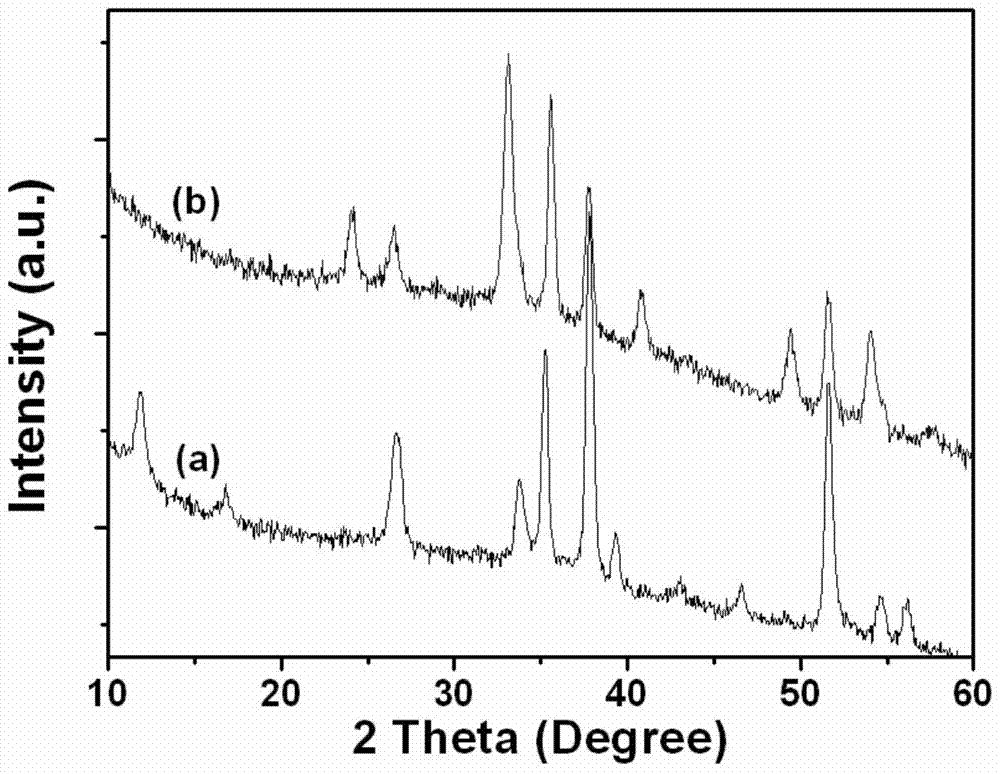

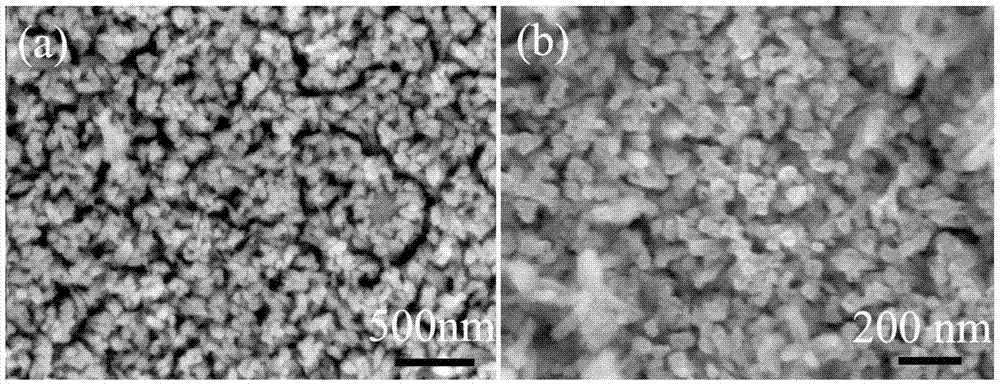

[0035] (1) the α-Fe that the embodiment of the present invention makes 2 o 3 Nanotube arrays are an ordered α-Fe 2 o 3 nanotube array films, these α-Fe 2 o 3 The nanotube arrays are uniformly distributed on the FTO substrate, and the α-Fe 2 o 3 The nanotube array film not only has a high density of oxygen vacancies, but also has a large specific surface area, a high carrier concentration, and a high photocatalytic activity. Therefore, the α-Fe prepared in the embodiment of the present invention 2 o 3 Nanotube arrays are well suited for use as photoelectrodes.

[0036] (2) The embodiment of the present invention is based on FeCl 3 、NaNO 3 , deionized water, nitrogen, and glass substrates covered with FTO as raw materials, these raw materials are not expensive raw materials, and in the preparation process, there is no need for compl...

Embodiment 1

[0042] A preparation of α-Fe based on hydrothermal method 2 o 3 A method for nanotube arrays, comprising the steps of:

[0043] Step 1, FTO pretreatment: Sonicate commercial FTO with a size of 30mm X 14mm in acetone, absolute ethanol, and deionized water for 30 minutes each, then wash with deionized water, and then dry the clean FTO in air.

[0044] Step 2, preparation of FeCl 3 and NaNO 3 The mixed solution: deionized water, FeCl 3 ·6H 2 O and NaNO 3 Mix according to the weight ratio of 1000:27:42.5 to obtain FeCl 3 and NaNO 3 mixed solution.

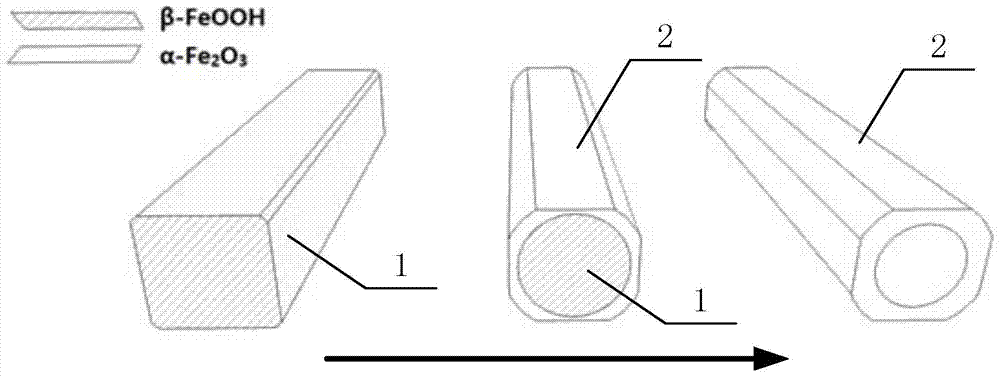

[0045] Step 3, preparation of β-FeOOH nanorod array: FeCl 3 and NaNO 3 20ml of the mixed solution was injected into a polytetrafluoroethylene liner with a volume of 50ml, and the glass substrate covered with FTO was placed obliquely on FeCl 3 and NaNO 3 In the mixed solution, the side of the glass substrate covered with FTO faces the inner wall of the polytetrafluoroethylene liner; then, the polytetrafluoroethylene liner is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com