A kind of reactor and quick start method for quickly starting anaerobic ammonium oxidation coupled nitrosation reaction

An anammox, fast-start technology, applied in the field of wastewater biological treatment, can solve the problems of long generation cycle of anammox bacteria, limited application and development, slow growth, etc., to achieve easy growth and reproduction, and avoid sludge loss. , the effect of stabilizing ecological conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

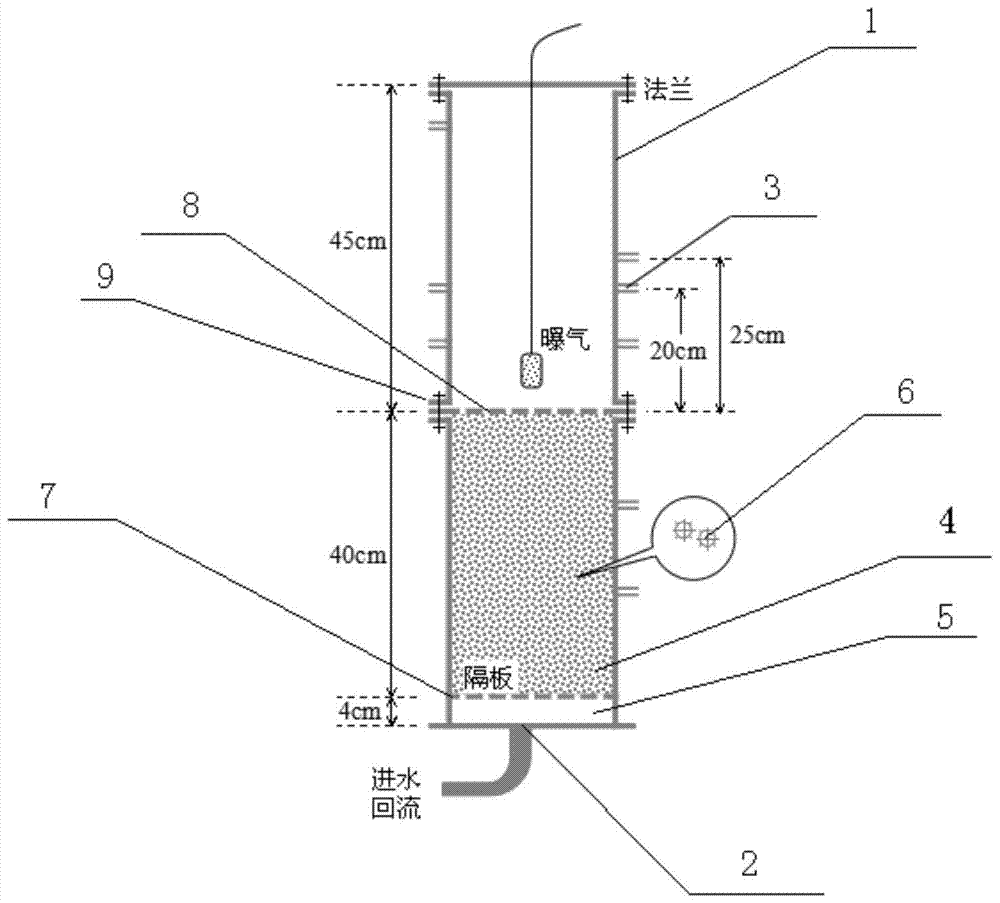

[0045] A reactor for quickly starting anaerobic ammonium oxidation coupling nitrosation reaction, the structure is as follows figure 1 Shown, comprise long columnar reactor 1, be provided with water inlet 2 at the bottom of reactor, sidewall upper part is provided with water outlet 3, be provided with gravel layer in the bottom of reactor, the thickness of gravel layer is 3cm, gravel The average diameter of the gravel in the layer is 5mm, and a water inlet pipe is laid in the gravel layer, and the water inlet pipe is connected to the water inlet. A lower partition 7 with holes is arranged above the gravel layer, and a packing layer 4 is arranged on the lower partition. The packing layer There are gaps inside, the porosity of the packing layer is 0.7, the thickness of the packing layer is 1 / 2 of the height of the reactor, the top of the packing layer is provided with an upper partition 8 with holes, and an aeration reactor is arranged on the upper part of the packing layer . T...

Embodiment 2

[0049] Utilize the reactor of embodiment 1 to quickly start the method for anaerobic ammonium oxidation coupling nitrosation reaction, comprise steps as follows:

[0050] (1) 1.5L of activated sludge is added to the packing layer area of the reactor of the quick-start anammox coupled nitrosation reaction of embodiment 1, the effective volume of the reactor is 5L, and the bottom is paved with a thickness of It is a gravel layer with a diameter of 3 cm and a diameter of 5 mm, and the water inlet pipe is laid in the gravel layer; the activated sludge is obtained from the sludge discharged from Jinan Everbright Water Affairs after filtering, screening, and pre-cultivation, and the sludge is removed by filtering and screening. Leaves, waste paper, waste plastics and other impurities in the sludge, and then feed the sludge into the lower reaction zone of the sequencing batch bioreactor.

[0051] (2) Add polyethylene filler particles to the filler layer area where sludge has been a...

Embodiment 3

[0055] Utilize the reactor of embodiment 1 to quickly start the method for anaerobic ammonium oxidation coupling nitrosation reaction, comprise steps as follows:

[0056] (1) 1.5L of anaerobic granular sludge is added to the packing layer area of the reactor of the quick-start anammox coupled nitrosation reaction of embodiment 1. The effective volume of the reactor is 5L, and the bottom is paved with There is a gravel layer with a thickness of 3cm and a diameter of 5mm, and the water inlet pipe is laid in the gravel layer; the anaerobic granular sludge is the sludge discharged from a paper mill in Zibo, and the sludge is added to the sequencing batch bioreactor in the lower reaction zone.

[0057] (2) Add polyethylene filler particles to the filler layer area where sludge has been added to form a filler layer. The porosity of the filler layer is 0.7, and the thickness of the filler layer is 1 / 2 of the height of the reactor. The polyethylene filler particles Stir and mix wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com