Rapid algae-liquid separation method for microalgae treatment wastewater

A technology for treating wastewater and microalgae, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as difficult promotion and application, difficult operation, secondary pollution, etc. Flexibility, convenient processing, and the effect of improving efficiency and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

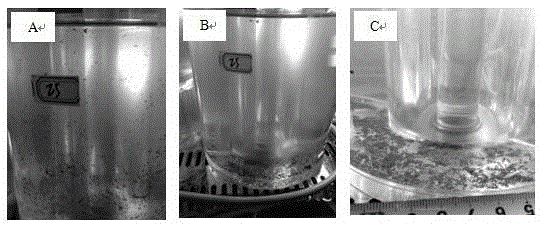

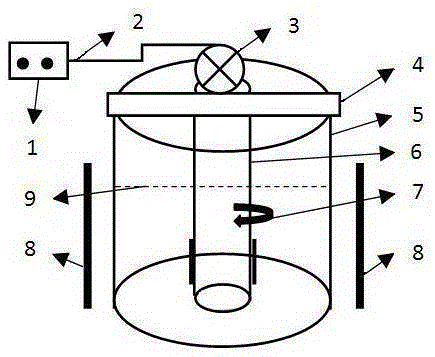

[0019] The following will be combined with figure 1 , 2 , 3 to describe the beneficial effects of the present invention in detail, aiming at helping readers better understand the essence of the present invention, but not constituting any limitation on the implementation and protection scope of the present invention.

[0020] 1. First collect the wastewater discharged from the sewage treatment plant and put it in the room for standby, and the COD of the wastewater Cr Potassium dichromate method is used, potassium persulfate oxidation ultraviolet spectrophotometry is used for TN, molybdenum antimony anti-spectrophotometry is used for TP, nanometer reagent photometry is used for ammonia nitrogen, and glass electrode method is used for pH. For details, refer to Water and Wastewater Monitoring and Analysis Methods (Fourth Edition)";

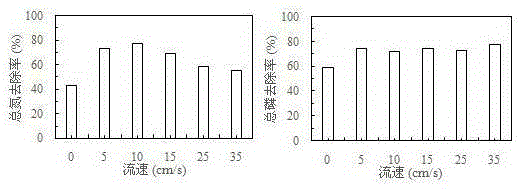

[0021] 2. Wastewater treatment is carried out in a controllable hydrodynamic plexiglass tank, controlling different hydrodynamic gradients, 0cm / s (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com