A biological wall breaking method for improving sludge dewatering performance

A sludge dewatering and sludge technology, applied in water/sludge/sewage treatment, sludge treatment, sludge treatment, etc., can solve problems such as unreported, achieve high ecological and hygienic safety, save processing energy Consume and dispose of space, the effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

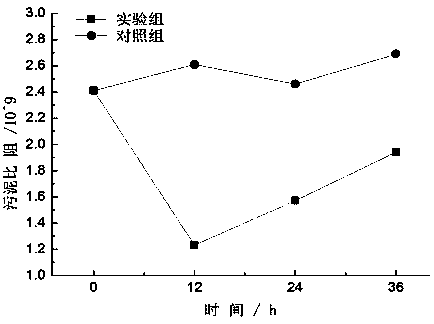

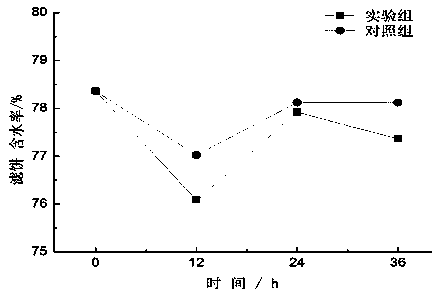

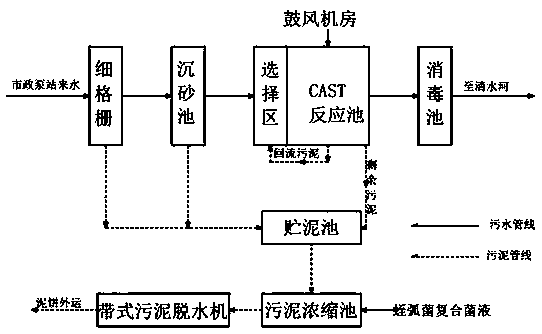

[0021] see figure 1 , figure 2 , using this process to carry out batch treatment of sludge in the laboratory, the treated sludge is the secondary sedimentation tank sludge produced by the oxidation ditch process to treat municipal sewage.

[0022] (1) Preparation of Bdellovibrio solution

[0023] Prepare the Bdellovibrio agent in advance, and the concentration of Bdellovibrio in the Bdellovibrio agent reaches 10 7 pfu / mL order of magnitude.

[0024] (2) Pretreatment of sludge

[0025] After natural sedimentation of the sludge, the lower layer of sludge was removed, and its water content basically reached 97-98%. The pH of the sludge was measured to be 6.75, and the temperature of the sludge was measured to be 25°C. In 1000mL glass bottles, each glass bottle contains 650mL sludge;

[0026] (3) Dosing of Bdellovibrio bacterial agent;

[0027] The experiment is divided into experimental group and control group.

[0028] The same batch of pretreated sludge was used as the s...

Embodiment 2

[0035] (1) Preparation of a Bdellovibrio composite bacterial agent

[0036] Prepare the mixed bacterial liquid of Bdellovibrio, photosynthetic bacteria and yeast flora in advance as the bacterial liquid of Bdellovibrio composite bacterial agent, wherein the concentration of Bdellovibrio is 10 8 pfu / mL order of magnitude.

[0037] (2) Pretreatment of sludge

[0038] The treated sludge is the oxidation ditch sludge produced by the oxidation ditch process to treat municipal sewage. After natural sedimentation of the sludge, the lower layer of sludge is removed, and its water content basically reaches 97-98%. The result of the sludge pH measurement is 7.0, and the sludge temperature is 18°C. In 1000mL glass bottles, each glass bottle contains 650mL sludge;

[0039] (3) Dosing of Bdellovibrio bacterial agent;

[0040] The dosing method of the bacterial agent is the same as in Example 1, and samples are taken every 12 hours to measure the specific resistance of the sludge and th...

Embodiment 3

[0044] (1) Preparation of a Bdellovibrio composite bacterial agent

[0045] Prepare the mixed bacterial liquid of Bdellovibrio, lactic acid bacteria group and Bacillus pumilus in advance as the bacterial liquid of Bdellovibrio compound bacterial agent, wherein the concentration of Bdellovibrio is 10 7 pfu / mL order of magnitude.

[0046] (2) Pretreatment of sludge

[0047] The treated sludge is the residual sludge produced by the SBR process for treating municipal sewage. After natural sedimentation of the sludge, the lower layer of sludge was removed, and its water content basically reached 96-97%. The pH of the sludge was measured to be 6.9, and the temperature of the sludge was measured to be 28°C. No adjustment is required. Stir the sludge evenly and start distributing to In 1000mL glass bottles, each glass bottle contains 650mL sludge;

[0048] (3) Dosing of Bdellovibrio bacterial agent;

[0049] The dosing method of the bacterial agent is the same as that of Example 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com