A kind of preparation method and product of early-strength polycarboxylate water-reducer containing carbon-oxygen heterocycle

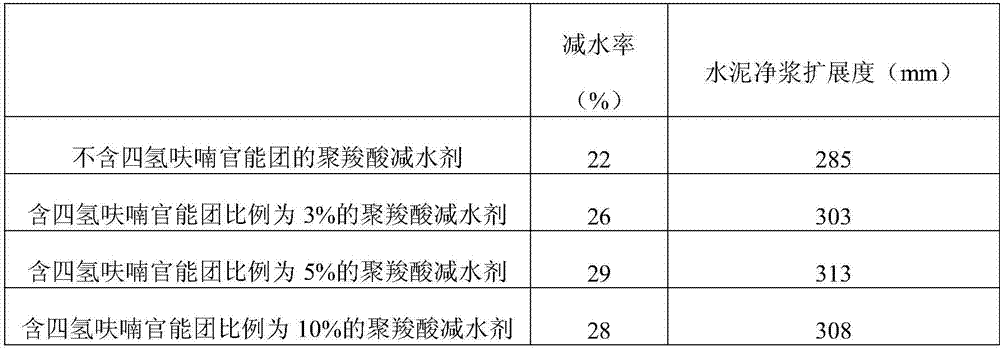

An early-strength polycarboxylate technology, which is applied in the field of preparation of early-strength polycarboxylate water reducers, can solve the problems of no significant improvement in performance, low air-entrainment, and rapid slump loss, and achieve structural strength The effect of accelerated rising speed and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

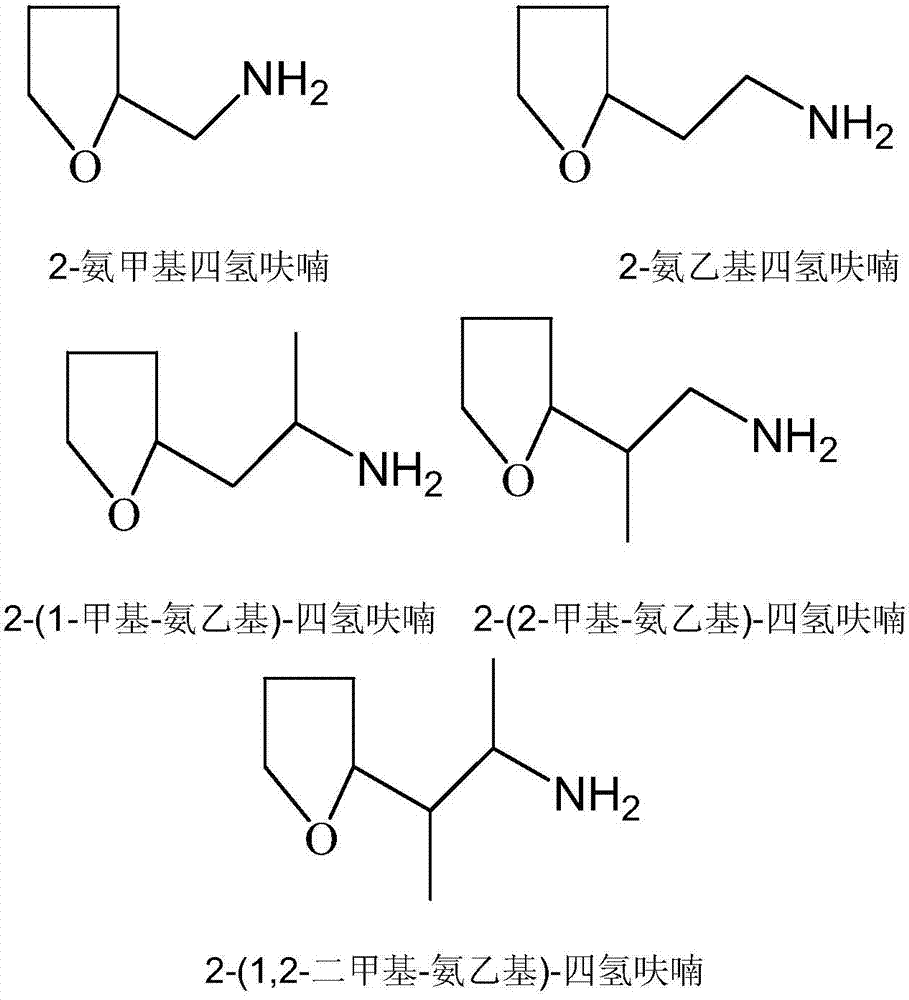

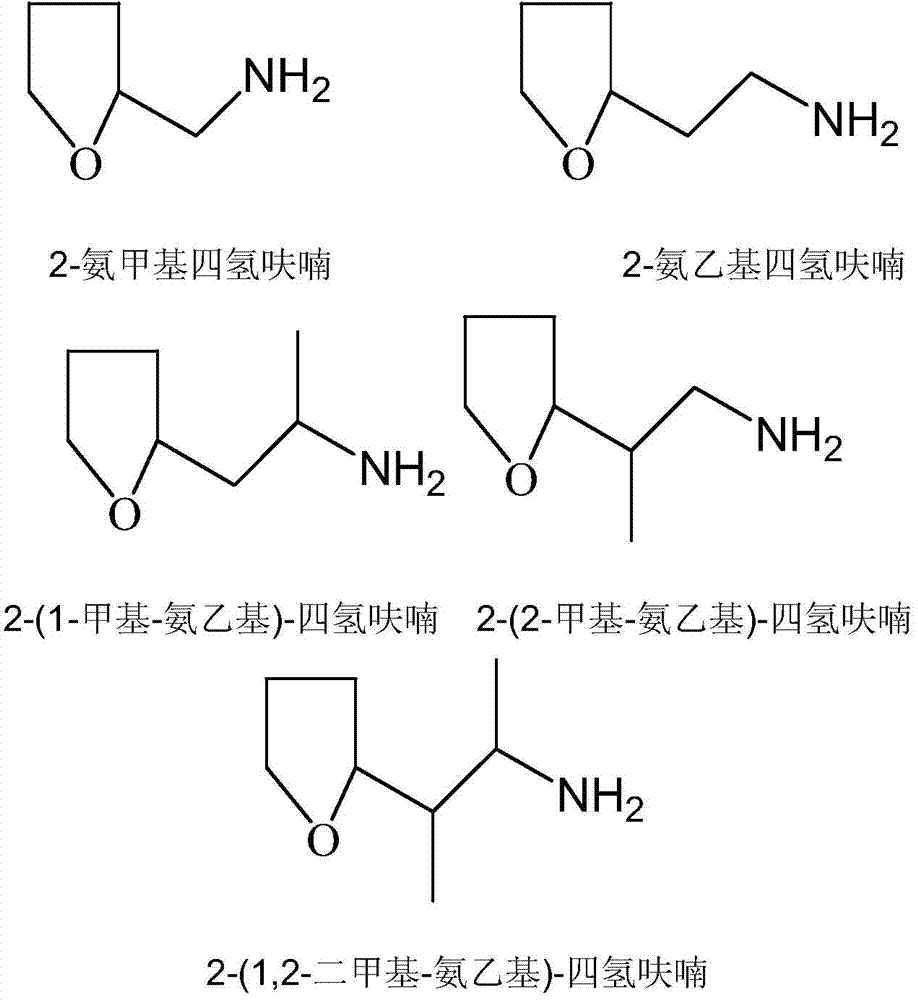

[0027] In a first aspect, the present invention provides a method for preparing an early-strength polycarboxylate water reducer containing a carbon-oxygen heterocycle, comprising the following steps:

[0028] (1) At a low temperature of less than 5°C, add excess dry maleic anhydride to the reaction vessel, stir rapidly, then slowly add aminotetrahydrofuran liquid, and keep the reaction temperature not exceeding 10°C in a water bath or ice-water bath, After all the aminotetrahydrofuran is added into the reaction vessel, the reaction is stirred for 15 minutes to 90 minutes to complete the amidation reaction and obtain an unsaturated tetrahydrofuran compound.

[0029] (2) Add the unsaturated tetrahydrofuran compound, unsaturated carboxylic acid and unsaturated polyether prepared in step (1) into the reaction vessel, and add deionized water to fully stir and mix until a clear solution is formed; The inorganic peroxide, and then, dropwise the reducing substance aqueous solution and...

Embodiment 1

[0043] At less than 5°C, add 500g of dry maleic anhydride to the reaction vessel, stir rapidly, and slowly add 350g of 2-aminomethyltetrahydrofuran dropwise while stirring in an ice-water bath, control the reaction temperature below 10°C, and complete the dropwise addition Afterwards, the stirring reaction was continued for 20 minutes, and the obtained product was an unsaturated tetrahydrofuran compound containing double bonds.

[0044] Add 2400g isopentenol polyoxyethylene ether TPEG (molecular weight 2400), 300g acrylic acid and 100g prepared unsaturated tetrahydrofuran compound to the reaction vessel at one time, add 2000g deionized water, mechanically stir at 20°C reaction temperature, fully Dissolve to form a clear solution, add 60g of ammonium persulfate, and then add 21g of chain transfer agent thioglycolic acid and an aqueous solution containing 2.0g of vitamin C dropwise at a constant rate. The dropping time is controlled at 150min. Add 30% NaOH alkali solution to neu...

Embodiment 2

[0046] At 3°C, add 500g of dry maleic anhydride to the reaction vessel, stir rapidly, and slowly add 300g of 2-(1,2-dimethyl-aminoethyl)-tetrahydrofuran while stirring in an ice-water bath to control the reaction The temperature is below 10°C, and after the dropwise addition is completed, the stirring reaction is continued for 30 minutes, and the obtained product is an unsaturated tetrahydrofuran compound containing double bonds.

[0047] Add 2400g of methallyl polyoxyethylene ether HPEG (molecular weight 2400), 300g of acrylic acid and 120g of the unsaturated tetrahydrofuran compound to the reaction vessel at one time, add 2000g of deionized water, and mechanically stir at a reaction temperature of 20°C. Fully dissolve to form a clear solution, add 65g of ammonium persulfate, and then add 21g of chain transfer agent thioglycolic acid and an aqueous solution containing 2.0g of vitamin C dropwise at a constant rate. The dropping time is controlled at 150min. . Add 30% NaOH alk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com