Polyethylene film for salt packaging bag

A polyethylene film and packaging bag technology, which is applied in the field of polyethylene film, can solve the problems of many corona treatment processes, little increase in surface tension, and high cost, so as to improve insufficient mechanical properties, save resources and costs, and increase surface tension. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

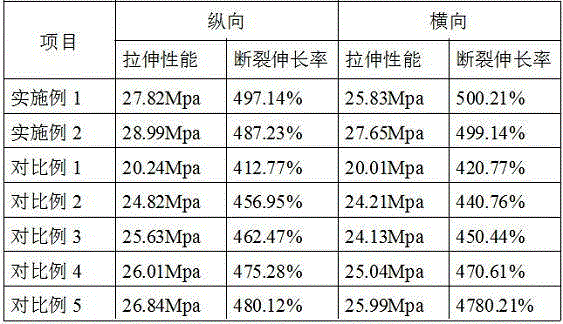

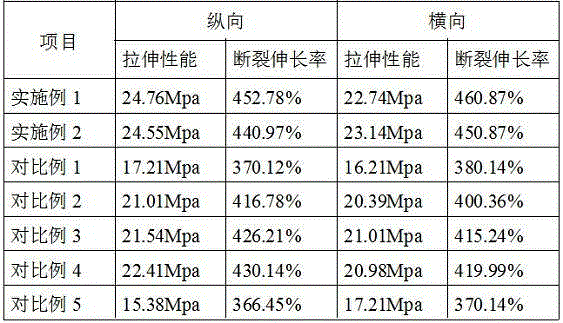

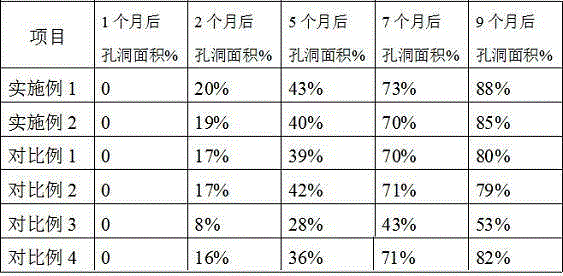

Examples

Embodiment 1

[0035] A kind of polyethylene film for salt packaging bag is made of the following raw materials in parts by weight:

[0036] 600 parts of polyethylene, 100 parts of sweet potato starch, 68 parts of crushed corn leaves, 50 parts of 1 μm calcium carbonate particles, 10 parts of sucrose fatty acid ester, 11 parts of sorbic acid, 20 parts of diluent, 50 parts of additives;

[0037] The polyethylene includes low-density polyethylene, medium-density polyethylene, high-density polyethylene and cross-linked polyethylene, and the ratio of the four is 13:18:7:6;

[0038] The crushed corn leaves are prepared by the following method: wash the corn leaves and dry them, soak the dried corn leaves in water until they become soft, then dry them and grind them into powder, add acetic acid to the powder until the powder becomes a slurry shape, and air-dried naturally, and then ground into powder again to obtain corn grits;

[0039] The diluent is a mixture of methanol and ethylene glycol in a...

Embodiment 2

[0047] A kind of polyethylene film for salt packaging bag is made of the following raw materials in parts by weight:

[0048] 630 parts of polyethylene, 120 parts of sweet potato starch, 90 parts of crushed corn leaves, 66 parts of 10 μm calcium carbonate particles, 15 parts of sucrose fatty acid ester, 20 parts of sorbic acid, 23 parts of diluent, and 85 parts of additives;

[0049] The polyethylene includes low-density polyethylene, medium-density polyethylene, high-density polyethylene and cross-linked polyethylene, and the ratio of the four is 25:22:7:9;

[0050] The crushed corn leaves are prepared by the following method: wash the corn leaves and dry them, soak the dried corn leaves in water until they become soft, then dry them and grind them into powder, add acetic acid to the powder until the powder becomes a slurry shape, and air-dried naturally, and then ground into powder again to obtain corn grits;

[0051] The diluent is a mixture of methanol and ethylene glycol i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com