Preparation process with convenient elimination of defective tetracycline hydrochloride for injection

A tetracycline hydrochloride, preparation technology, applied in the field of medicine, can solve the problem of unqualified finished products of tetracycline hydrochloride for injection, and achieve the effect of avoiding unlabeled and empty loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

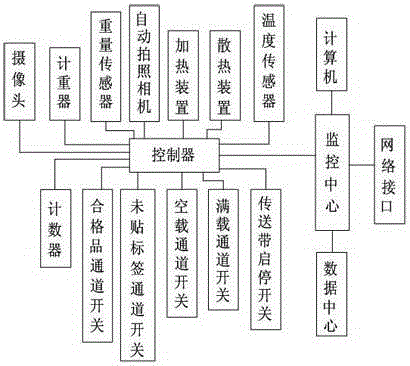

[0022] Such as figure 1 Shown, the preparation technology of the tetracycline hydrochloride for injection that is convenient to reject unqualified product, comprises the following steps:

[0023] 1) Preparation of tetracycline hydrochloride: Mix tetracycline hydrochloride urea double salt with organic alcohol mixed solvent at a ratio of 1g: 6mL, stir continuously at 10°C for 10 minutes, add hydrochloric acid, and filter after continuous stirring; transfer the obtained filtrate into a crystallizer After heating up, add seed crystals when the system temperature reaches 30°C, continue to heat up to 45°C, and incubate at a constant temperature for 30 minutes; then lower the temperature of the suspension to 10°C at a cooling rate of 5°C / min; filter the obtained crystal slurry, wash with a solvent, Obtain tetracycline hydrochloride crystal product; The mol ratio of effective HCl in described tetracycline hydrochloride urea double salt and hydrochloric acid is 1:1; Described organic ...

Embodiment 2

[0027] Such as figure 1 Shown, the preparation technology of the tetracycline hydrochloride for injection that is convenient to reject unqualified product, comprises the following steps:

[0028] 1) Preparation of tetracycline hydrochloride: Mix tetracycline hydrochloride urea double salt with organic alcohol mixed solvent in a ratio of 1g: 8mL, stir continuously at 15°C for 10min, add hydrochloric acid, and filter after continuous stirring; transfer the obtained filtrate into a crystallizer After the temperature rises, when the system temperature reaches 35°C, add seed crystals, continue to heat up to 50°C, and incubate at a constant temperature for 30 minutes; then lower the temperature of the suspension to 15°C at a rate of 8°C / min; filter the obtained crystal slurry, and wash with a solvent. Obtain tetracycline hydrochloride crystal product; The mol ratio of effective HCl in described tetracycline hydrochloride urea double salt and hydrochloric acid is 1:2; Described organ...

Embodiment 3

[0032] Such as figure 1 Shown, the preparation technology of the tetracycline hydrochloride for injection that is convenient to reject unqualified product, comprises the following steps:

[0033] 1) Preparation of tetracycline hydrochloride: Mix tetracycline hydrochloride urea double salt with organic alcohol mixed solvent in a ratio of 1g: 10mL, stir continuously at 18°C for 10min, add hydrochloric acid, and filter after continuous stirring; transfer the obtained filtrate into a crystallizer After heating up, add seed crystals when the system temperature reaches 35°C, continue to heat up to 48°C, and incubate at a constant temperature for 30 minutes; then lower the temperature of the suspension to 18°C at a cooling rate of 6°C / min; filter the obtained crystal slurry, wash with a solvent, Obtain tetracycline hydrochloride crystal product; The mol ratio of effective HCl in described tetracycline hydrochloride urea double salt and hydrochloric acid is 1:2; Described organic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com