Environmental-protection drying device

A drying device, an environment-friendly technology, applied in heating devices, manure drying, drying solid materials, etc., can solve the problems of different particle sizes and different drying degrees, and achieve the effect of strengthening heat preservation, high work efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

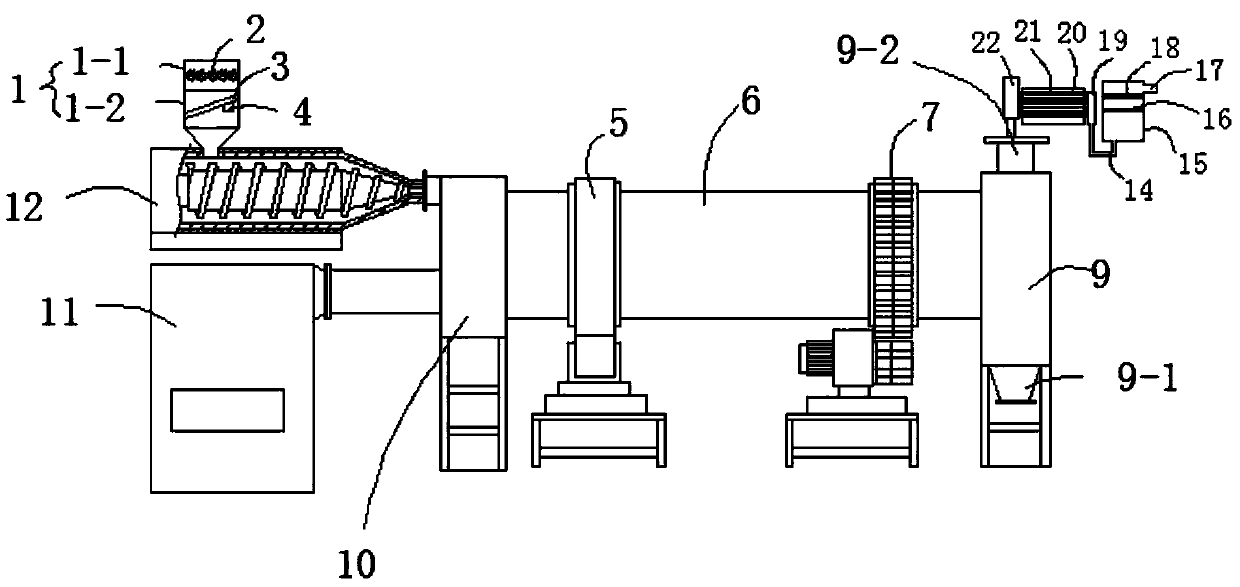

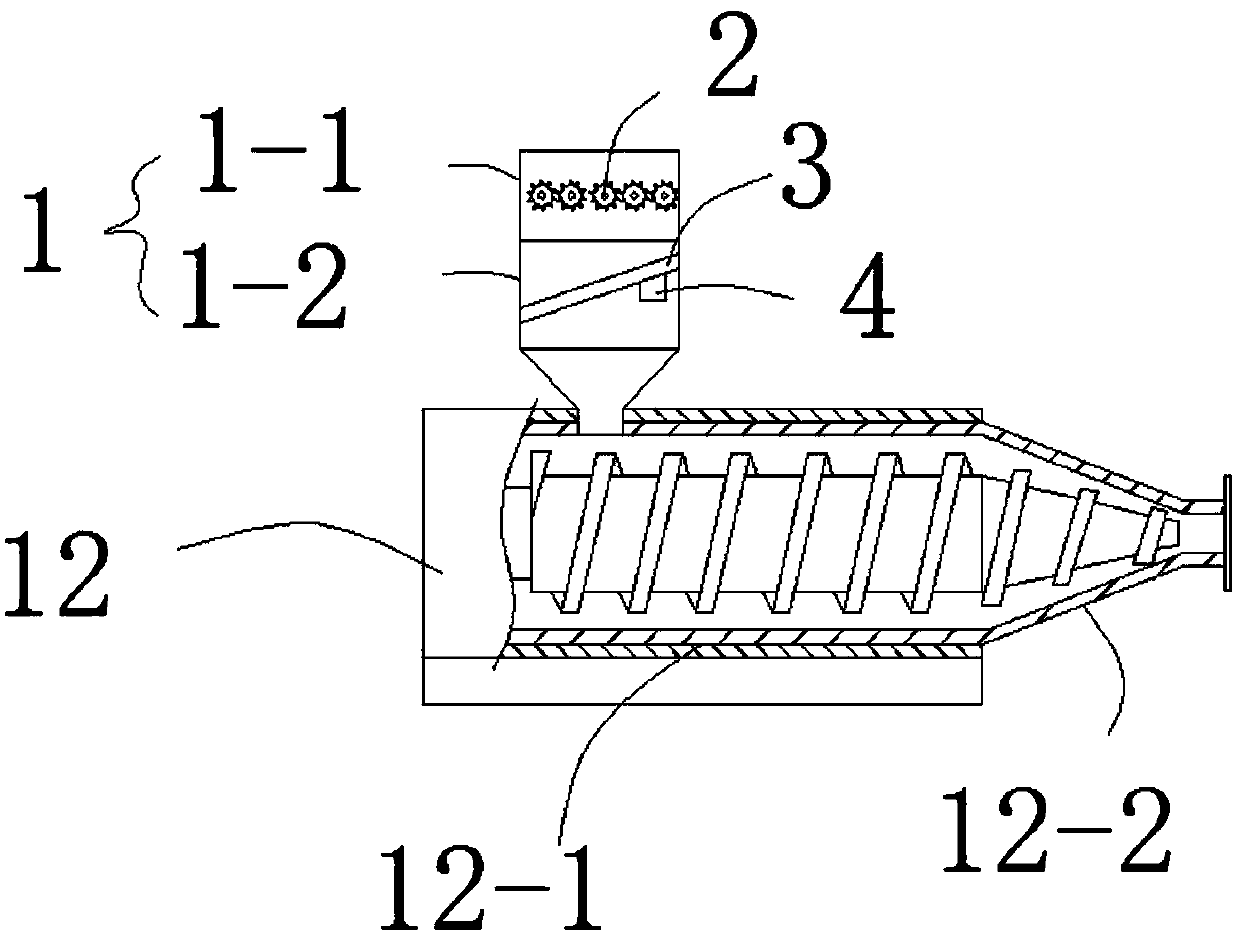

[0027] Such as Figures 1 to 5 As shown, the present embodiment provides an environment-friendly drying device, comprising a feed head 10 and a discharge head 9, a drum 6 is arranged between the feed head 10 and the discharge head 9, and the feed head 10 It is connected with a combustion chamber 11, and it is characterized in that the feed port of the feed head 10 is connected with a composite feed mechanism, the composite feed mechanism includes a conveying chamber 12, and the conveying chamber 12 includes a cylindrical chamber 12 welded into one -1 and conical cavity 12-2, the outlet of conical cavity 12-2 is connected to the feed port of feed head 10, and the cylindrical cavity 12-1 is provided with a compound feed hopper 1, which includes the upper The pre-crushing chamber 1-1 and the vibrating feeding chamber 1-2 connected with the cylindrical chamber 12-1 below, the vibrating screen 3 is arranged in the vibrating feeding chamber 1-2, and the composite vibrating mechanism...

Embodiment 2

[0031] This embodiment is further optimized on the basis of embodiment 1, specifically:

[0032] The drum 6 is provided with a gear drive mechanism 7 which drives the drum 6 to rotate, and the drum 6 is provided with a driven rotation mechanism 5 .

[0033] The composite thermal insulation layer 6-2 includes several layers of glass fiber layers 6-2.1 and several layers of aluminum foil layers 6-2.2, the glass fiber layers 6-2.1 and aluminum foil layers 6-2.2 are stacked alternately, and the adjacent two layers of aluminum foil layers 6-2.2 No Contact.

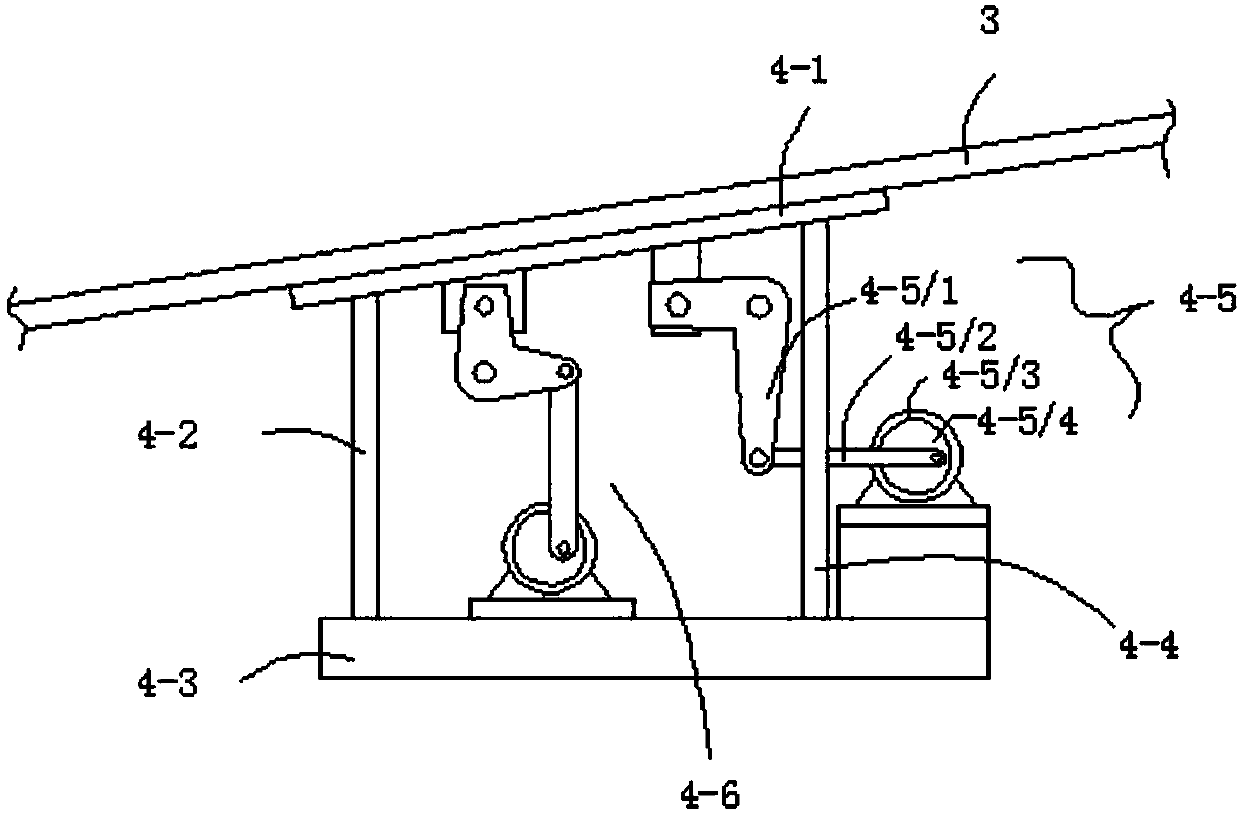

[0034] Described composite vibration mechanism 4 comprises vibrating plate 4-1 and support base plate 4-3, is provided with connecting rod A4-2 and connecting rod B4-4 between vibrating plate 4-1 and supporting base plate 4-3, and supporting base plate 4- 3 is provided with a horizontal vibration mechanism 4-5 for controlling the horizontal vibration of the vibration plate 4-1 and a vertical vibration mechanism 4-6 for control...

Embodiment 3

[0036] This embodiment is further optimized on the basis of embodiment 1 or 2, specifically:

[0037] The horizontal vibration mechanism 4-5 includes a horizontal motor 4-5 / 3, a horizontal connecting rod 4-5 / 2, and one end connected to the horizontal connecting rod 4-5 / 2 and the other end connected to the vibration The horizontal curved plate 4-5 / 1 is movably connected to the bottom side of the middle part of the plate 4-1, the output end of the horizontal motor 4-5 / 3 is provided with a horizontal turntable 4-5 / 4, the horizontal turntable 4-5 / 4 and the horizontal connecting rod 4 -5 / 2 is movably connected, and the connection between the horizontal turntable 4-5 / 4 and the horizontal connecting rod 4-5 / 2 is far away from the center of circle of the horizontal turntable 4-5 / 4.

[0038] A plurality of flaps 13 are arranged inside the drum 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com