A kind of novel ionic liquid and preparation method thereof

A technology for ionic liquids and lithium-ion batteries, applied in the chemical industry, can solve problems such as poor solubility of lithium salts and hinder the application of ionic liquids, and achieve excellent wettability of polyimide, good solubility of lithium salts, and high thermal stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

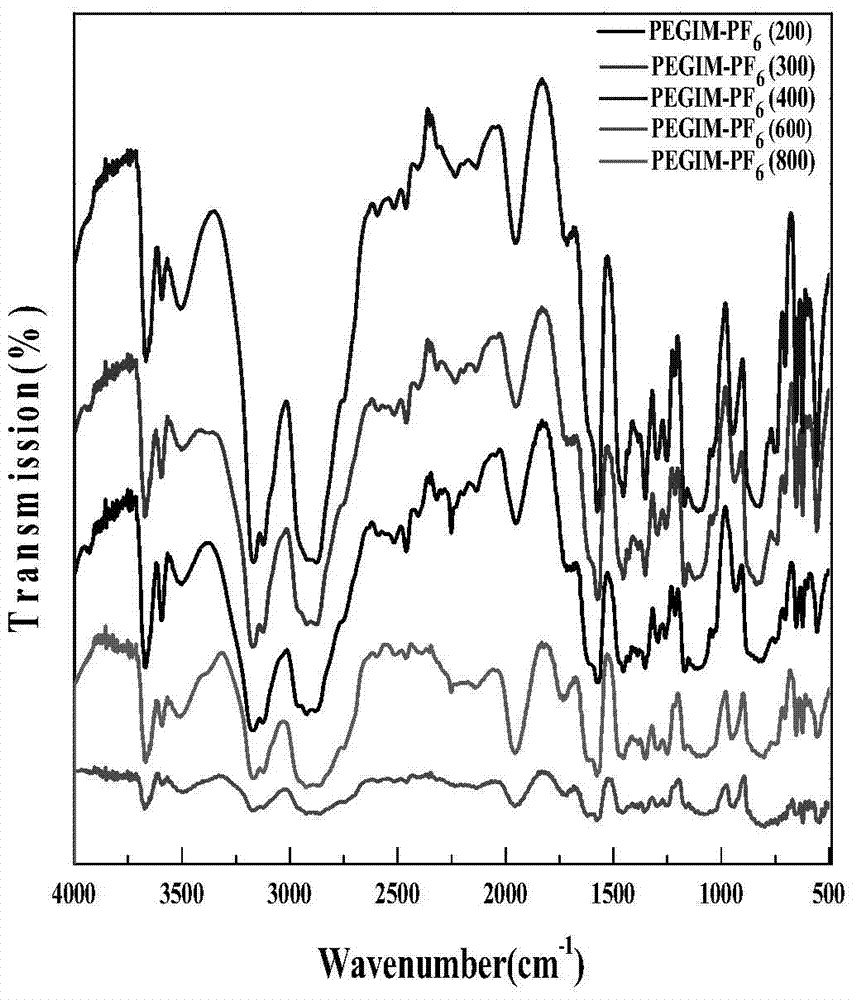

Embodiment 1

[0029] Add 0.001 mol redistilled PEG (average molecular weight 200) into the three-necked flask. Then, take 50mL of thionyl chloride and place it in a constant pressure dropping funnel. Subsequently, thionyl chloride was added dropwise into polyethylene glycol at 20°C. After the dropwise addition of thionyl chloride was completed, the reaction was maintained for 12 hours. Next, vacuum distillation was carried out to remove the remaining thionyl chloride. The obtained light yellow liquid was put into a vacuum drying oven and dried at 40° C. for 12 h. Finally, the resulting product is stored in a vacuum desiccator for future use.

[0030]Under nitrogen protection, 0.001 mol of chlorinated PEG (the average molecular weight of PEG is 200) was added into the three-necked flask. The temperature was raised to 60 °C, and then 0.5 mL of redistilled 1-methylimidazole was slowly added with stirring. After 24 h of reaction, the reaction was stopped and the temperature was lowered to ...

Embodiment 2

[0034] Add 0.01 mol of redistilled PEG (average molecular weight: 300) into the three-necked flask. Then, take 60 mL of thionyl chloride and place it in a constant pressure dropping funnel. Subsequently, thionyl chloride was added dropwise into polyethylene glycol at 40°C. After the dropwise addition of thionyl chloride was completed, the reaction was maintained at 80°C for 8h. Next, vacuum distillation was carried out to remove the remaining thionyl chloride. The obtained light yellow liquid was put into a vacuum drying oven and dried at 50° C. for 12 h. Finally, the resulting product is stored in a vacuum desiccator for future use.

[0035] Under the protection of nitrogen, 0.01 mol of chlorinated PEG (the average molecular weight of PEG is 300) was added into the three-necked flask. The temperature was raised to 80 °C, and then 1.2 mL of redistilled 1-methylimidazole was slowly added with stirring. After 20 h of reaction, the reaction was stopped and the temperature wa...

Embodiment 3

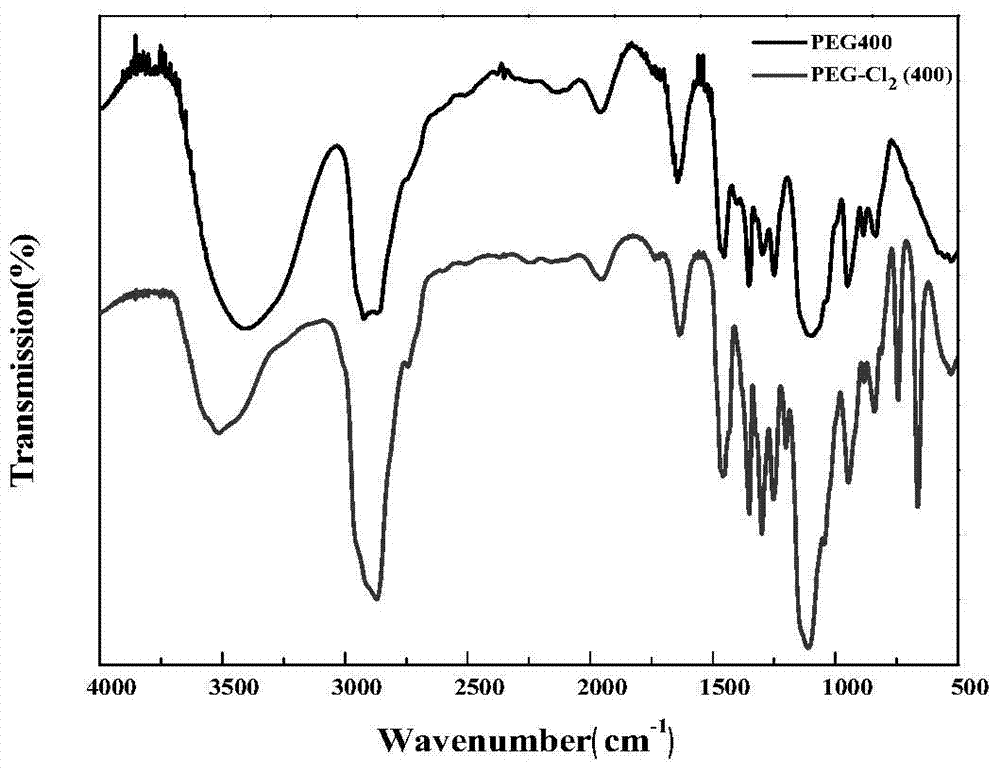

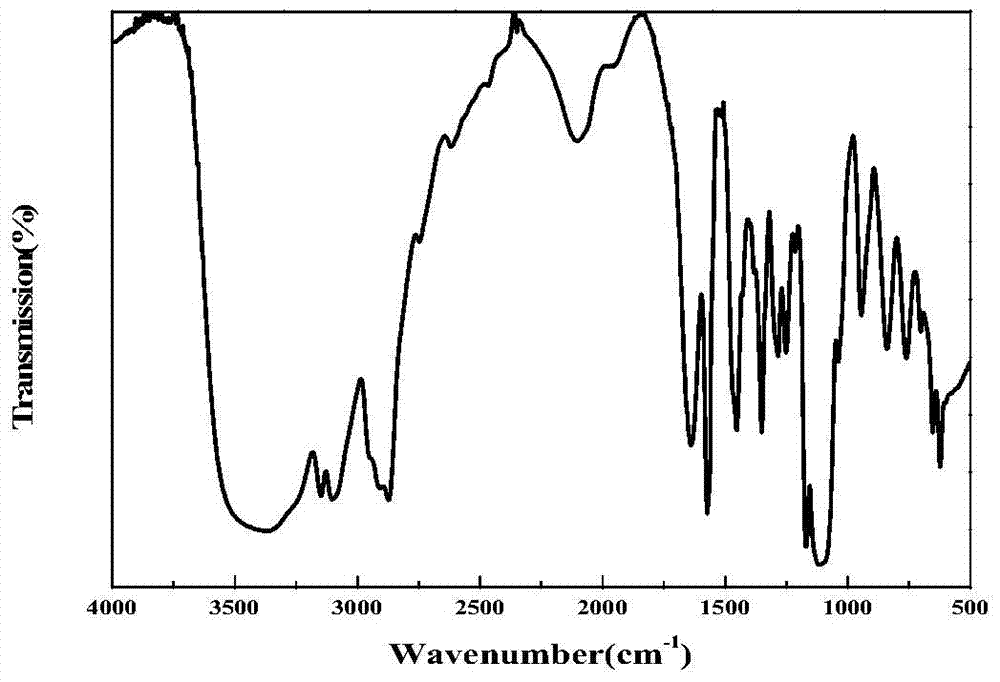

[0039] Add 0.01 mol redistilled PEG (average molecular weight 400) into the three-neck flask. Then, take 60 mL of thionyl chloride and place it in a constant pressure dropping funnel. Subsequently, thionyl chloride was added dropwise into polyethylene glycol at 40°C. After the dropwise addition of thionyl chloride was completed, the reaction was maintained at 80°C for 8h. Then, vacuum distillation was carried out to remove the remaining thionyl chloride. The obtained light yellow liquid was put into a vacuum drying oven and dried at 50° C. for 12 h. Finally, the resulting product is stored in a vacuum desiccator for future use.

[0040] Under the protection of nitrogen, 0.01 mol of chlorinated PEG (the average molecular weight of PEG is 400) was added into the three-necked flask. The temperature was raised to 80 °C, and then 1.2 mL of redistilled 1-methylimidazole was slowly added with stirring. After 20 h of reaction, the reaction was stopped and the temperature was lowe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap