High-conductivity polyimides-graphene composite material and preparation method thereof

A technology of polyimide and high conductivity, which is applied in the field of high conductivity polyimide-graphene composite materials and its preparation, and can solve the problems of difficult dispersion of graphene, high percolation threshold, cumbersome process, etc. , to achieve the effect of simple and practical molding method, high electrical conductivity and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040]Add 0.6 g of self-made polyimide microspheres into a 100 ml single-necked flask, add 54 g of deionized water, stir and disperse evenly, and obtain a dispersion of polyimide microspheres. Add 0.6 mg of self-made graphene oxide (see: Journal of the American Chemical Society 1958; 80:1339 for specific preparation method) into 6 g of deionized water, and ultrasonically disperse for 1 hour to obtain a graphene oxide dispersion. Then the graphene oxide dispersion was slowly added to the polyimide microsphere dispersion, and stirred at 25° C. for 1 h to obtain a graphene oxide-coated polyimide microsphere dispersion. Next, 0.02 g of hydrazine hydrate was added to the solution, and the reaction solution was heated to 90° C. for 24 hours of reaction. Centrifuged and washed 3 times to obtain polyimide microspheres coated with reduced graphene oxide.

[0041] Wherein, the preparation method of polyimide microsphere is as follows:

[0042] (1) Add polyimide to N,N-dimethylacetamid...

Embodiment 2

[0050] Add 0.6 g of self-made polyimide microspheres into a 100 ml single-necked flask, add 48 g of deionized water, stir and disperse evenly, and obtain a dispersion of polyimide microspheres. Add 1.2 mg of self-made graphene oxide into 6 g of deionized water, and ultrasonically disperse for 1 hour to obtain a graphene oxide dispersion. Then the graphene oxide dispersion was slowly added to the polyimide microsphere dispersion, and stirred at 25° C. for 1 h to obtain a graphene oxide-coated polyimide microsphere dispersion. Next, 0.04 g of hydrazine hydrate was added to the solution, and the reaction solution was heated to 90° C. for 24 hours of reaction. Centrifuged and washed 3 times to obtain polyimide microspheres coated with reduced graphene oxide.

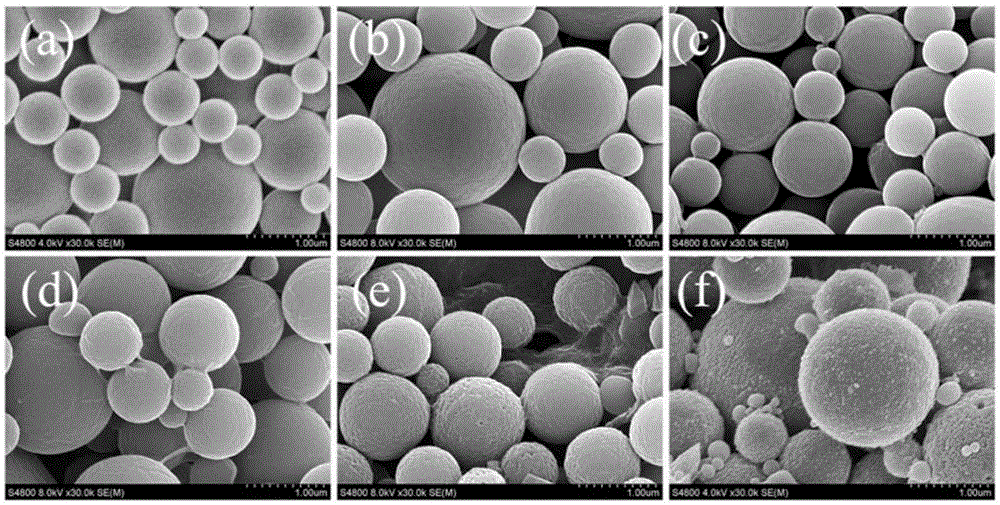

[0051] Scanning electron microscopy showed that the surface of the microspheres was slightly coated with a layer of graphene, and the intensity of the PI characteristic peak on the Raman spectrum peak was weakened.

[0052...

Embodiment 3

[0054] Add 0.6 g of self-made polyimide microspheres into a 100 ml single-necked flask, add 42 g of deionized water, stir and disperse evenly, and obtain a dispersion of polyimide microspheres. Add 1.8 mg of self-made graphene oxide into 18 g of deionized water, and ultrasonically disperse for 1 hour to obtain a graphene oxide dispersion. Then the graphene oxide dispersion was slowly added to the polyimide microsphere dispersion, and stirred at 25° C. for 1 h to obtain a graphene oxide-coated polyimide microsphere dispersion. Next, 0.05 g of hydrazine hydrate was added to the solution, and the reaction solution was heated to 90° C. for 24 hours of reaction. Centrifuged and washed 3 times to obtain polyimide microspheres coated with reduced graphene oxide.

[0055] Scanning electron microscopy showed that the surface of the microspheres was slightly coated with a layer of graphene, and the intensity of the PI characteristic peak on the Raman spectrum peak was weakened.

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com