Production technology for reflective heat-insulation coating

A reflective thermal insulation coating and production process technology, applied in the coating field, can solve the problems of poor thermal insulation performance, unfavorable environmental protection, high cost, etc., and achieve the effects of excellent performance, overcoming the influence of the environment, and high reflectivity and emissivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

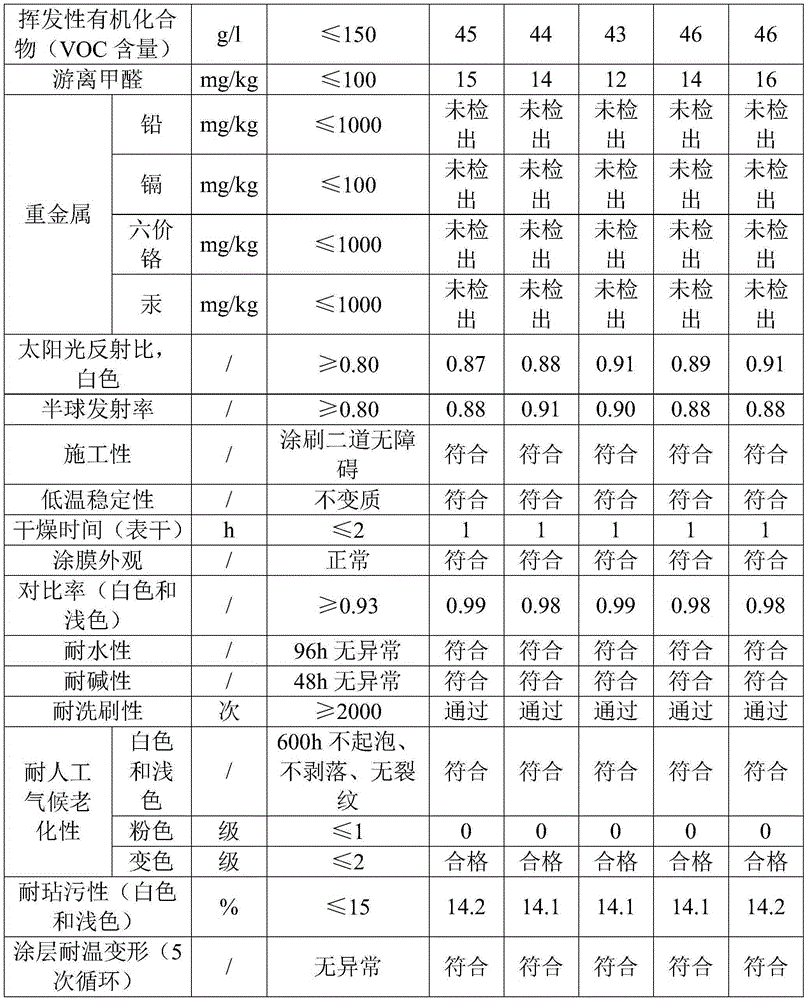

Examples

Embodiment 1

[0029] A production process of reflective heat-insulating paint, said production process comprising the following steps:

[0030] (1) Add 160 parts of water, 2.5 parts of dispersant, 4.8 parts of defoamer, and 4.8 parts of bactericide into the reaction kettle according to the weight ratio, and stir evenly;

[0031] (2) Add 0.48 parts of nano-tin antimony oxide, 0.8 part of nano-alumina zinc, and 0.18 parts of surface-grafted nano-titanium dioxide microcapsule composite particles into the reactor according to the proportioning by weight, and adjust the rotating speed to be stirred for 45 minutes under the condition of 1300r / min, get a dispersed system;

[0032] (3) Add 30 parts of polyacrylic resin, 10 parts of polyurethane resin, and 10 parts of silicone acrylic resin to the reaction kettle according to the proportion by weight, and stir for 25 minutes under the condition of adjusting the rotating speed of 1000r / min to obtain the mixture;

[0033] (4) Mix 16 parts of film-for...

Embodiment 2

[0038] A production process of reflective heat-insulating paint, said production process comprising the following steps:

[0039] (1) Add 165 parts of water, 3 parts of dispersant, 5 parts of defoamer and 5 parts of bactericide into the reaction kettle according to the proportioning by weight, and stir evenly;

[0040] (2) Add 0.8 part of nano-tin antimony oxide, 1.2 part of nano-alumina zinc, and 0.2 part of surface-grafted nano-titanium dioxide microcapsule composite particles into the reactor according to the proportioning by weight, and adjust the speed of stirring for 50 min under the condition of 1500 r / min, get a dispersed system;

[0041] (3) Add 35 parts of polyacrylic resin, 12 parts of polyurethane resin, and 12 parts of silicone acrylic resin to the reaction kettle according to the proportion by weight, and stir for 25 minutes under the condition of adjusting the rotating speed of 1000r / min to obtain the mixture;

[0042] (4) Mix 18 parts of film-forming aid, 0.4 ...

Embodiment 3

[0047] A production process of reflective heat-insulating paint, said production process comprising the following steps:

[0048] (1) Add 180 parts of water, 3.6 parts of dispersant, 5.6 parts of defoamer, and 6 parts of bactericide into the reaction kettle according to the weight ratio, and stir evenly;

[0049] (2) Add 1.2 parts of nano-tin antimony oxide, 1.8 parts of nano-alumina zinc, and 0.24 parts of surface-grafted nano-titanium dioxide microcapsule composite particles into the reactor according to the proportioning by weight, and adjust the rotating speed to be stirred for 45 minutes under the condition of 2000r / min, get a dispersed system;

[0050] (3) Add 40 parts of polyacrylic resin, 15 parts of polyurethane resin, and 15 parts of silicone acrylic resin to the reaction kettle according to the proportion by weight, and stir for 30 minutes under the condition of adjusting the rotating speed of 1100r / min to obtain the mixture;

[0051] (4) Mix 20 parts of film-formi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com