A kind of high chromium vanadium titanium pellets

A technology of high-chromium vanadium-titanium pellets and vanadium-titanium ore, which is applied in the field of pellets, can solve the problems of unfavorable blast furnace smelting, high reduction expansion rate, and low compressive strength of pellets, so as to improve metallurgical properties and reduce powder , The effect of reducing the cost per ton of iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 and the comparative example raw material composition mass percentage content of prior art are shown in Table 1.

[0024] Table 1 Example 1 and comparative example raw material composition mass percentage content table

[0025] raw material Iron Concentrate % High chromium vanadium titanite% Magnesium boron concentrate% Added bentonite% Example 1 56.8 42 1.2 1

[0026] comparative example 60 40 0 1

[0027] The iron concentrate, high-chromium vanadium-titanium ore, boron-magnesium concentrate and added bentonite are weighed according to the ratio in Table 1, and then mixed with a powerful mixer, and the mixed material is mixed with a disc pelletizer The pellets are formed, and the pellets are roasted using a conventional rotary kiln process.

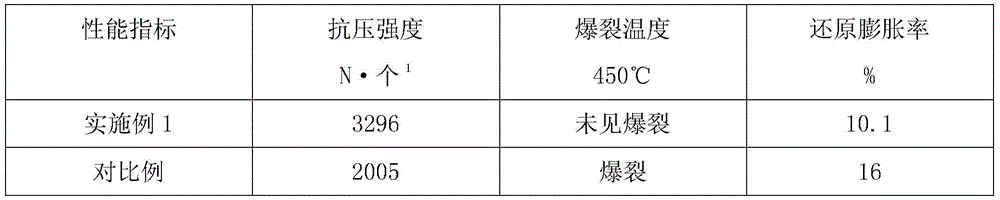

[0028] The pellets produced in Example 1 and Comparative Example were tested experimentally, and the performance test results are shown in Table 2.

[0029] Table 2 Pe...

Embodiment 2

[0033] See Table 3 for the mass percentage content of the raw materials in Example 2 and the comparative example of the prior art.

[0034] Table 3 Example 2 and comparative example raw material composition mass percentage content table

[0035] raw material Iron Concentrate % High chromium vanadium titanite% Magnesium boron concentrate% Added bentonite% Example 2 40.2 58 1.8 2.2 comparative example 60 40 0 2.2

[0036] The iron concentrate, high-chromium vanadium-titanium ore, boron-magnesium concentrate and added bentonite are weighed according to the ratio in Table 3, and then mixed with a powerful mixer, and the mixed material is mixed with a disc pelletizer The pellets are formed, and the pellets are roasted using a conventional rotary kiln process.

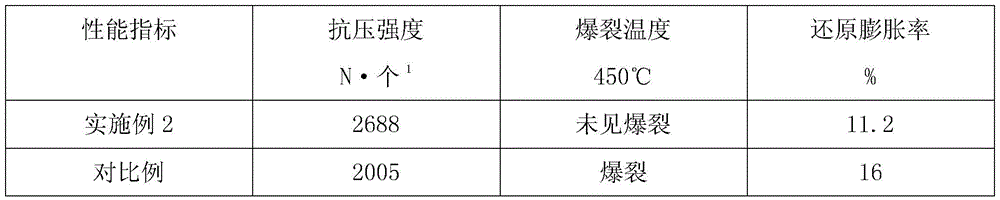

[0037] The pellets produced in Example 2 and Comparative Example were tested experimentally, and the performance test results are shown in Table 4.

[0038] Table 4 Performance inspec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com