Manufacturing method for spray pipe of propeller

A propeller and nozzle technology, which is applied in the field of preparation of propeller nozzles, can solve the problems of small application range and shortage, and achieve the effects of wide application range, controllable quality and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

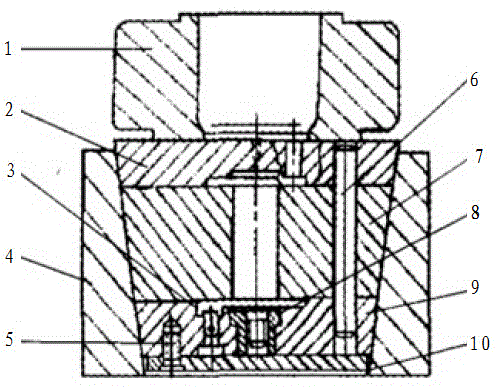

Image

Examples

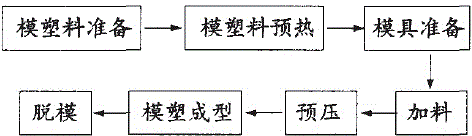

Embodiment 1

[0028] Weigh 30 grams of phenolic glass fiber reinforced molding compound, put it into a cloth belt, put it in the oven, bake for 10 minutes, take it out, and heat the mold to 160 o When C, disconnect the thermostat and return to 30 o C, turn on the temperature controller and raise the temperature to 150 o C. Open the mold, clean the mold, apply the release agent evenly, and assemble the mold. Put the phenolic glass fiber reinforced molding compound into the upper mold cavity of the nozzle mold, close the die head, put the upper mold cavity on the nozzle mold, close the mold and inject pressure, and wait until the phenolic glass fiber reinforced molding compound is on the upper mold When the cavity becomes soft, pressurize the mold, and slowly inject the phenolic glass fiber reinforced molding compound into the cavity. After the phenolic glass fiber reinforced molding compound is completely injected, deflate the mold once for low temperature vulcanization for 180 seconds, and...

Embodiment 2

[0030] Weigh 50 grams of phenolic glass fiber reinforced molding compound, put it into a cloth belt, put it in the oven, bake for 10 minutes, take it out, and heat the mold to 190 o When C, disconnect the thermostat and return the temperature to 50 o C, turn on the temperature controller to raise the temperature to 160 o C. Open the mold, clean the mold, apply the release agent evenly, and assemble the mold. Put the phenolic glass fiber reinforced molding compound into the upper mold cavity of the nozzle mold, close the die head, put the upper mold cavity on the nozzle mold, close the mold and inject pressure, and wait until the phenolic glass fiber reinforced molding compound is on the upper mold When the cavity becomes soft, pressurize the mold, and slowly inject the phenolic glass fiber reinforced molding compound into the cavity. After the phenolic glass fiber molding compound is completely injected, deflate the mold once for low-temperature vulcanization for 180 seconds,...

Embodiment 3

[0032] Weigh 40 grams of phenolic glass fiber reinforced molding compound, put it into a cloth belt, put it in the oven, bake for 10 minutes, take it out, and heat the mold to 130 o When C, disconnect the thermostat and return to 30 o C, turn on the temperature controller to raise the temperature to 140 oC. Open the mold, clean the mold, apply the release agent evenly, and assemble the mold. Put the phenolic glass fiber reinforced molding compound into the upper mold cavity of the nozzle mold, close the die head, put the upper mold cavity on the nozzle mold, close the mold and inject pressure, and wait until the phenolic glass fiber reinforced molding compound is on the upper mold When the cavity becomes soft, pressurize the mold, slowly inject the phenolic glass fiber reinforced molding compound into the cavity, and after the phenolic glass fiber reinforced molding compound is completely injected, deflate the mold once for low temperature vulcanization for 180 seconds, press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com