Manufacturing method for high-simulation artificial stalactite

A production method and stalactite imitation technology, applied in decorative arts, crafts for producing decorative surface effects, decorative structures, etc., can solve problems such as increased production costs and labor costs, difficult process operations, and rising market prices, and achieve Good decoration and beautification effects, natural appearance streamlines, and good appearance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

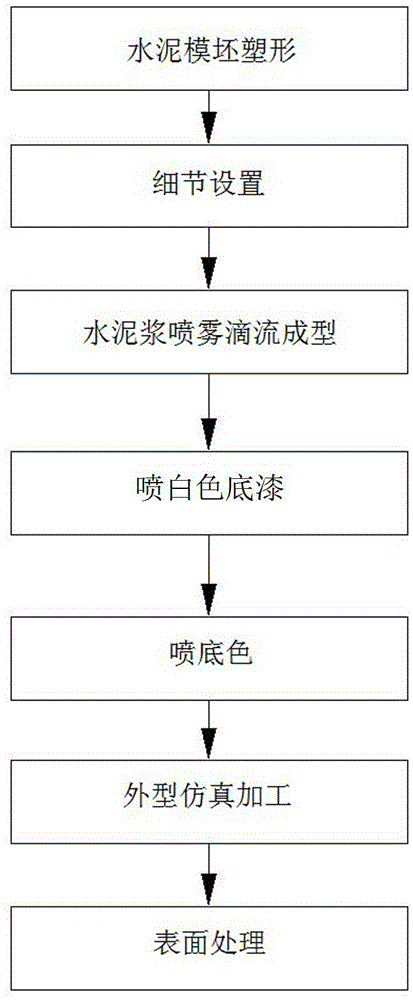

[0048] Such as figure 1 A high-simulation artificial stalactite manufacturing method is shown, including mold base shaping, detail modification, paste-like substance spray drip molding (primary product molding), white primer (intermediate product molding), spraying base color, and appearance Simulation processing, surface treatment (advanced product molding), the specific steps are as follows:

[0049] a. Cement mold blank shaping: mold shaping or manual shaping, materials include wood, soil, arbitrary stone in natural materials; concrete, gypsum, artificial stone, metal, plastic, foam plastic, etc. in artificial materials (can be attached Cement slurry, gypsum slurry, double-flying powder slurry and other artificial pasty materials that can be attached to the surface of objects) random substances to create artificial stalactite bases with structures similar to natural stalactite configurations, and artificial stalactite bases can be left Functional holes may or may not be re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com