Method for continuous production of high-quality alkyl benzene sulfonic acid

A high-quality technology of alkylbenzene sulfonic acid, applied in the field of daily chemical industry, can solve the problems of continuous production feasibility exploration, untested, and removal of free sulfuric acid, and achieve low price, reduce irritation, and improve utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

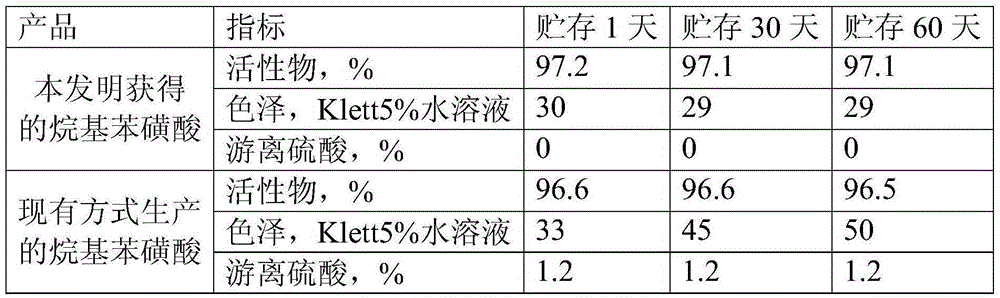

[0021] Embodiment 1: in the continuous production of existing sulfonic acid, alkylbenzene generates alkylbenzenesulfonic acid anhydride, enters homogeneous system by 3t / h; Simultaneously, mass concentration is the calcium hydroxide aqueous emulsion of 45% by 100kg / h The speed of h enters the homogeneous system. Control the homogenization speed to 1400rpm, control the reaction temperature to 40°C, and control the reaction time to 20 minutes. After the reaction, centrifuge to obtain a finished product of benzenesulfonic acid with good quality, and store it at 35°C for 60 days in the later stage. The changes of active matter, color and free sulfuric acid, the specific indicators are as follows:

[0022]

Embodiment 2

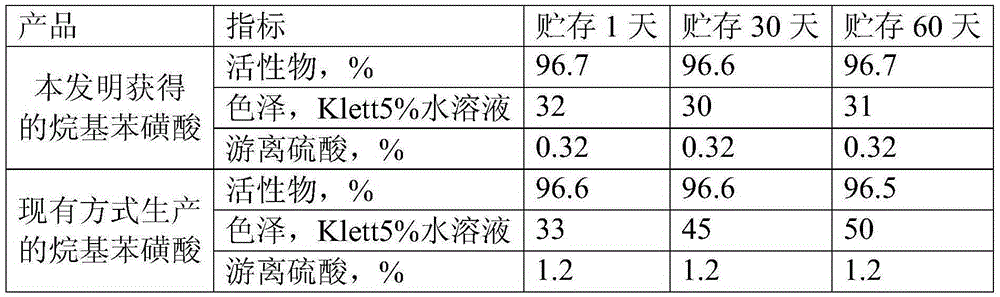

[0023] Embodiment 2: in the continuous production of existing sulfonic acid, alkylbenzene generates alkylbenzenesulfonic acid anhydride, enters homogeneous system by 3t / h; Simultaneously, mass concentration is the calcium chloride aqueous solution of 30% by 100kg / h The speed enters the homogeneous system. Control the homogenization speed to 1000rpm, control the reaction temperature to 30°C, and control the reaction time to 30 minutes. After the reaction, centrifuge to obtain a finished product of benzenesulfonic acid with good quality, and store it at 35°C for 60 days in the later stage. The changes of active matter, color and free sulfuric acid, the specific indicators are as follows:

[0024]

Embodiment 3

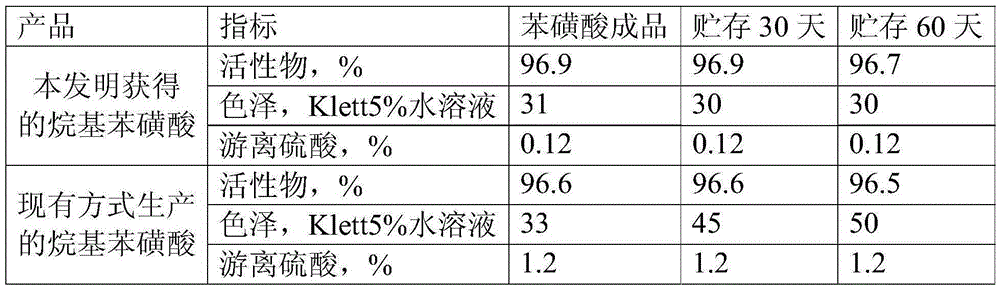

[0025] Embodiment 3: in the continuous production of existing sulfonic acid, alkylbenzene generates alkylbenzenesulfonic acid anhydride, enters homogeneous system by 3t / h; Simultaneously, mass concentration is the calcium bicarbonate aqueous solution of 60% by 100kg / h The speed enters the homogeneous system. Control the homogenization speed to 2000rpm, control the reaction temperature to 50°C, and control the reaction time to 15 minutes. After the reaction is completed, centrifuge to obtain a finished product of benzenesulfonic acid with good quality, and store it at 35°C for 60 days in the later stage. The changes of active matter, color and free sulfuric acid, the specific indicators are as follows:

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com