Martensitic stainless steel for building structure fastener and manufacturing method thereof

A martensitic stainless steel and building structure technology, applied in the field of martensitic stainless steel, can solve the problems of poor cold forming performance, poor corrosion resistance, prone to galvanic corrosion, etc., achieve good hot working performance and cold working performance, and improve cold working Formability and corrosion resistance, effect of improving hot workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

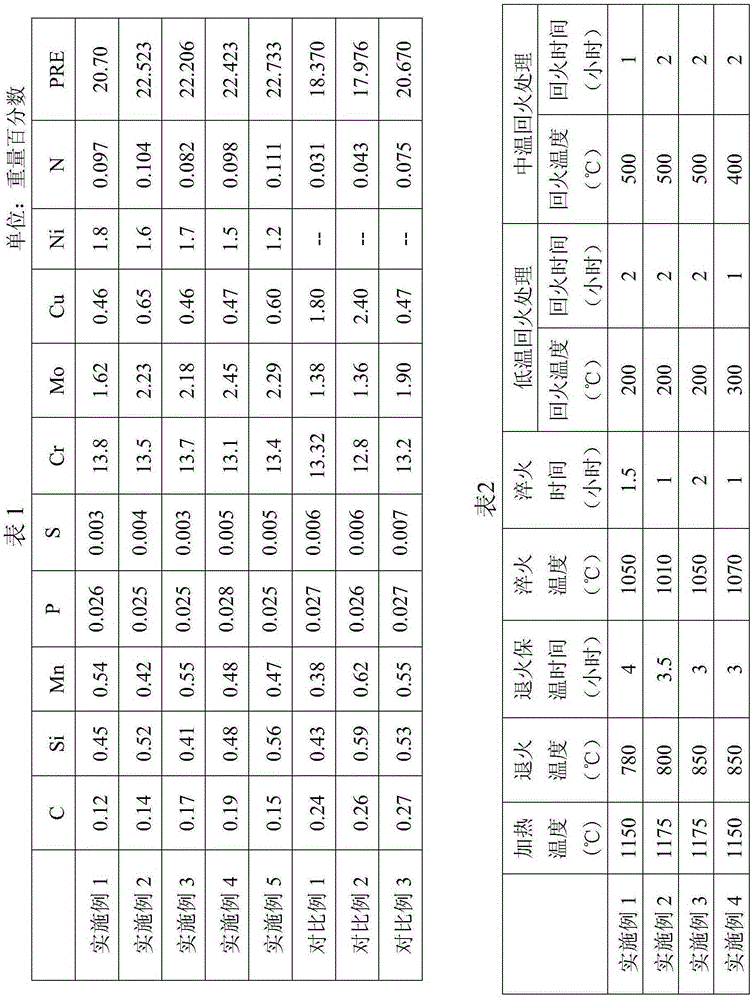

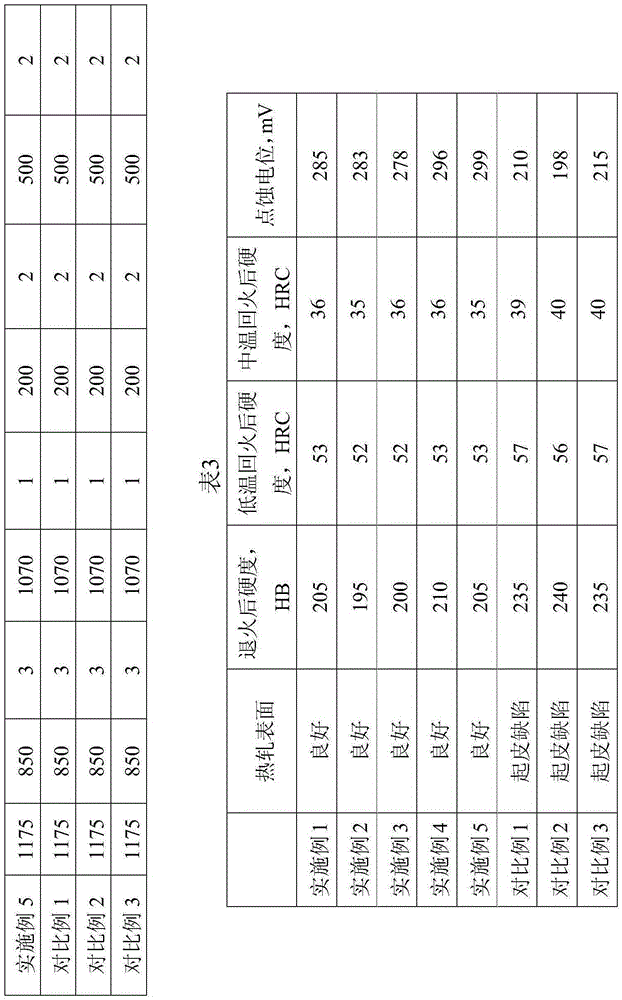

[0048] Table 1 is the composition of the steel of the embodiment of the present invention and the comparative example, table 2 is the process parameter of the embodiment of the present invention and the comparative example, and table 3 is the hot-rolled surface quality, mechanical properties and pitting potential of the embodiment of the present invention and the comparative example .

[0049] The martensitic stainless steel for building fasteners described in the embodiment of the present invention is smelted by electric furnace+AOD two-step method according to the composition in Table 1, and after being cast into a billet, it is then heated, hot rolled, annealed+pickling, and heat treated, wherein , the heating temperature is 1100-1200°C, the annealing temperature is 780-860°C, and the annealing holding time is 3-4 hours; the heat treatment process in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pitting potential | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com