Locked-rotor protector of high pressure flow regulating valve

A technology of flow regulating valve and protector, applied in valve details, valve device, valve operation/release device, etc., to achieve the effect of low cost, stable operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

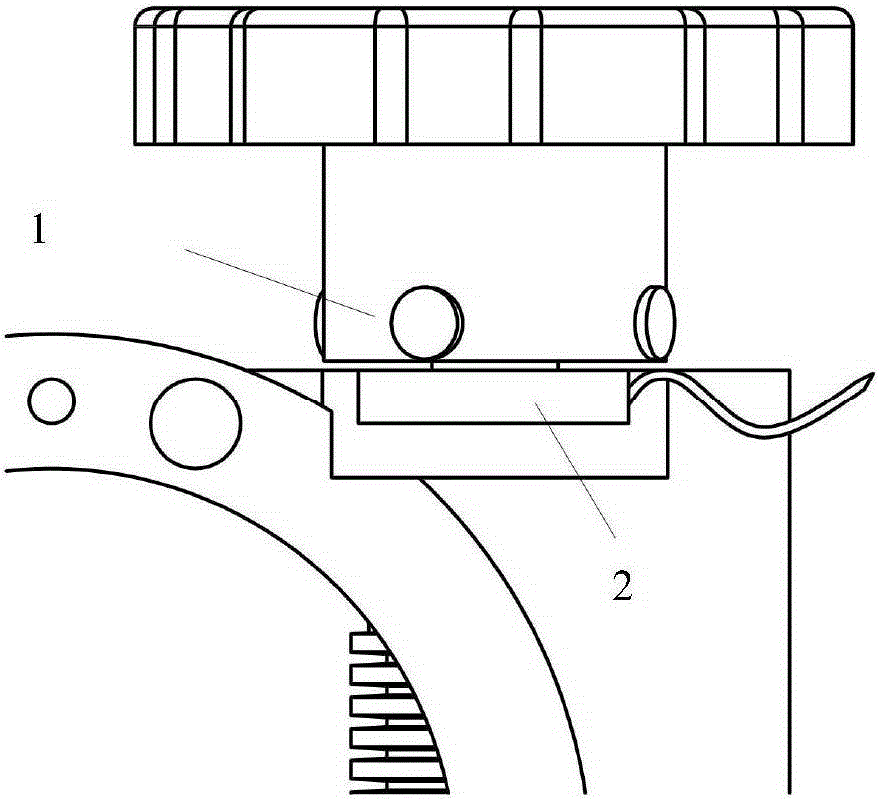

[0015] The present invention will be further described below in conjunction with accompanying drawing:

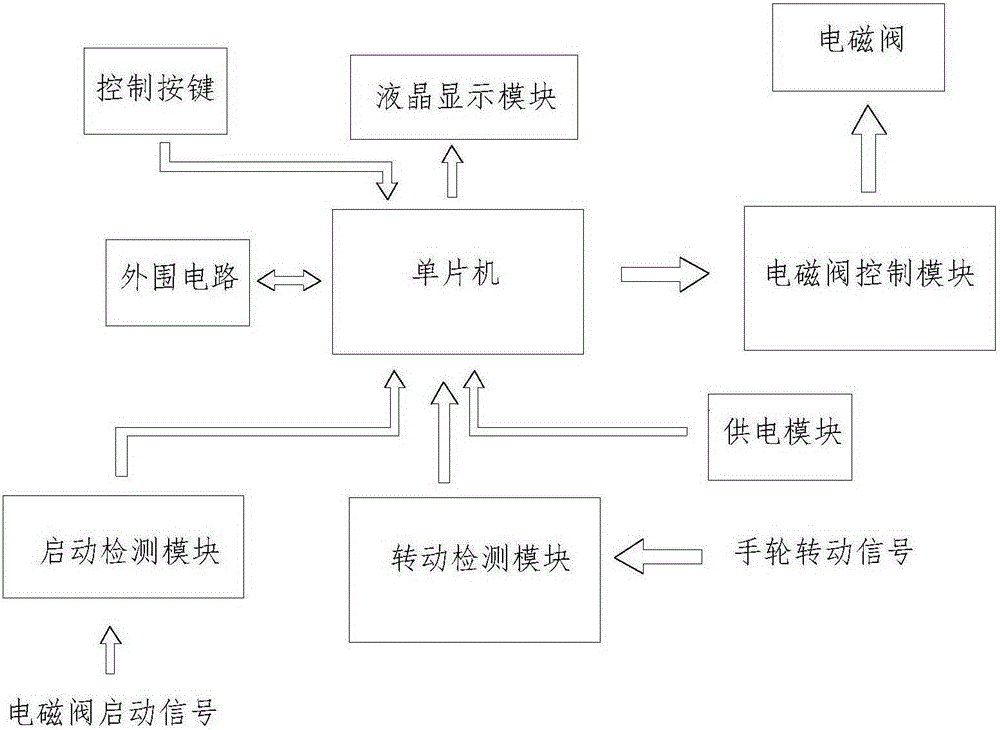

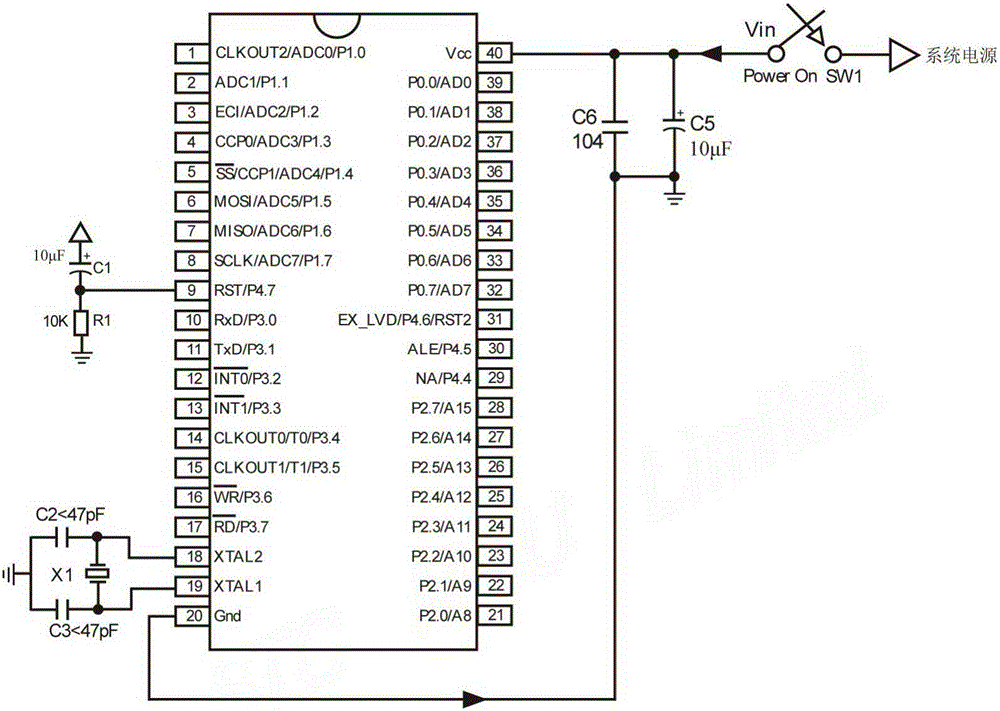

[0016] The purpose of this kind of high-pressure flow regulating valve locked-rotor protector is to disconnect the motor to protect the motor, control board and transmission rod of the high-pressure flow regulating valve when the regulating valve is fouled. It has a single-chip microcomputer and a control button coordinated with the single-chip microcomputer, a peripheral circuit, a liquid crystal display module and a power supply module. The single-chip microcomputer adopts STC12C5A60S2, and its peripheral circuit includes a reset circuit and a crystal oscillator circuit. The circuit diagram of the power supply module is as follows Figure 6 As shown, it can be installed on the high-pressure flow regulating valve, and can obtain 220V AC mains power locally. In order to obtain the 5V DC required by the system, it is necessary to step down, rectify and stabilize the 220V AC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com